1.Applicability of laser welding technology features to materials

①High energy density:

Concentrated laser beam energy enables deep melting welds for high melting point variations in iron-copper based materials (SINTD10), but copper evaporation and segregation need to be controlled.

②Small heat affected zone:

Low impact on carbon sensitive areas of FC0208 cast iron reduces the risk of thermal cracking, but rapid cooling may lead to hardened tissue (e.g. martensite).

③Non-contact machining:

Suitable for porous materials (e.g. SINTD10), reduces mechanical stresses, but the effect of porosity on melt pool stability should be noted.

2.Feasibility of laser welding FC0208 (gray cast iron)

①High carbon content:

Prone to form hard and brittle martensite, leading to cold cracking.

②Graphitization element:

Welding thermal cycle may destroy the graphite distribution, affecting the performance.

Solution:

Preheating and slow cooling:

Preheat to 300~400℃ before welding and use heat preservation measures after welding (e.g. sand cooling).

Selection of filler material:

Use nickel-based wires (e.g. ENi-CI) to inhibit carbon diffusion and reduce cracks.

Optimization of process parameters:

Adopt low power and slow speed to reduce heat input and avoid local overheating.

3.Feasibility of laser welding of SINTD10 (iron-copper base alloy)

①Large difference in melting points:

Iron (1538°C) and copper (1083°C) can lead to uneven fusion and copper segregation.

②Porosity:

Powder metallurgy porosity may lead to porosity or slag entrapment.

Solution:

Optimization of process parameters:

Adopt pulsed laser mode to reduce copper evaporation; adjust spot position to balance the ratio of iron to copper melting.

Auxiliary gas protection:

Use argon or helium to disperse the plasma and prevent porosity.

Pre-treatment:

Hot Isostatic Pressure (HIP) densification before welding, or select high energy density laser (e.g. fiber laser) to close the porosity.

4.Dissimilar material laser welding between FC0208 and SINTD10

①Metallurgical mismatch:

Brittle intermetallic compounds (e.g. Fe-Cu) tend to form at the Fe-Cu interface.

②Difference in coefficients of thermal expansion:

leads to concentration of stresses in the weld.

Solution:

①Interlayer transition:

Addition of nickel- or copper-based foils (e.g. pure nickel or bronze) to mitigate interfacial reactions.

②Composite process:

Combined laser and arc welding to reduce heat input and improve molten pool fluidity.

③Post-weld treatment:

Annealing treatment (500~600℃) to eliminate stress and improve joint toughness.

5.Precautions

①Surface Cleaning:

Thoroughly remove oil and oxides to avoid air holes (refer to Abstract 3).

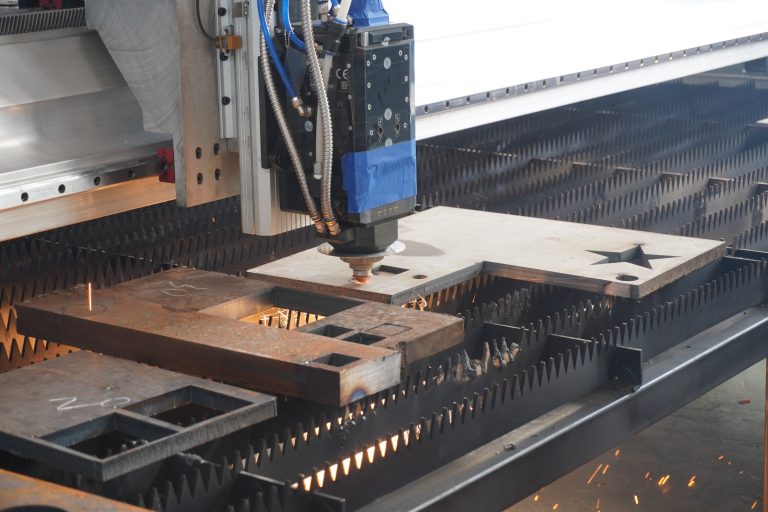

②Equipment selection:

Prefer fiber laser or disc laser, high energy density and stable beam quality.

③Quality Inspection:

Use ultrasonic or X-ray flaw detection to detect internal defects, combined with metallographic analysis to assess tissue homogeneity.

6.Conclusion

Laser welding of FC0208 and SINTD10 is feasible, but the process needs to be optimized for the material properties:

FC0208:

preheating, cooling and Ni-based filler material, controlled heat input.

SINTD10:

Sint-D10 is a German standard powder metallurgy material.

Optimization of laser parameters, densification pre-treatment, suppression of copper segregation.

Dissimilar welding:

Relies on the design of the interlayer and the composite process to ensure metallurgical compatibility at the interface.

It is recommended to validate the process parameters by testing and to evaluate the performance of the welded joints in combination with microstructure analysis (e.g. SEM, EDS).