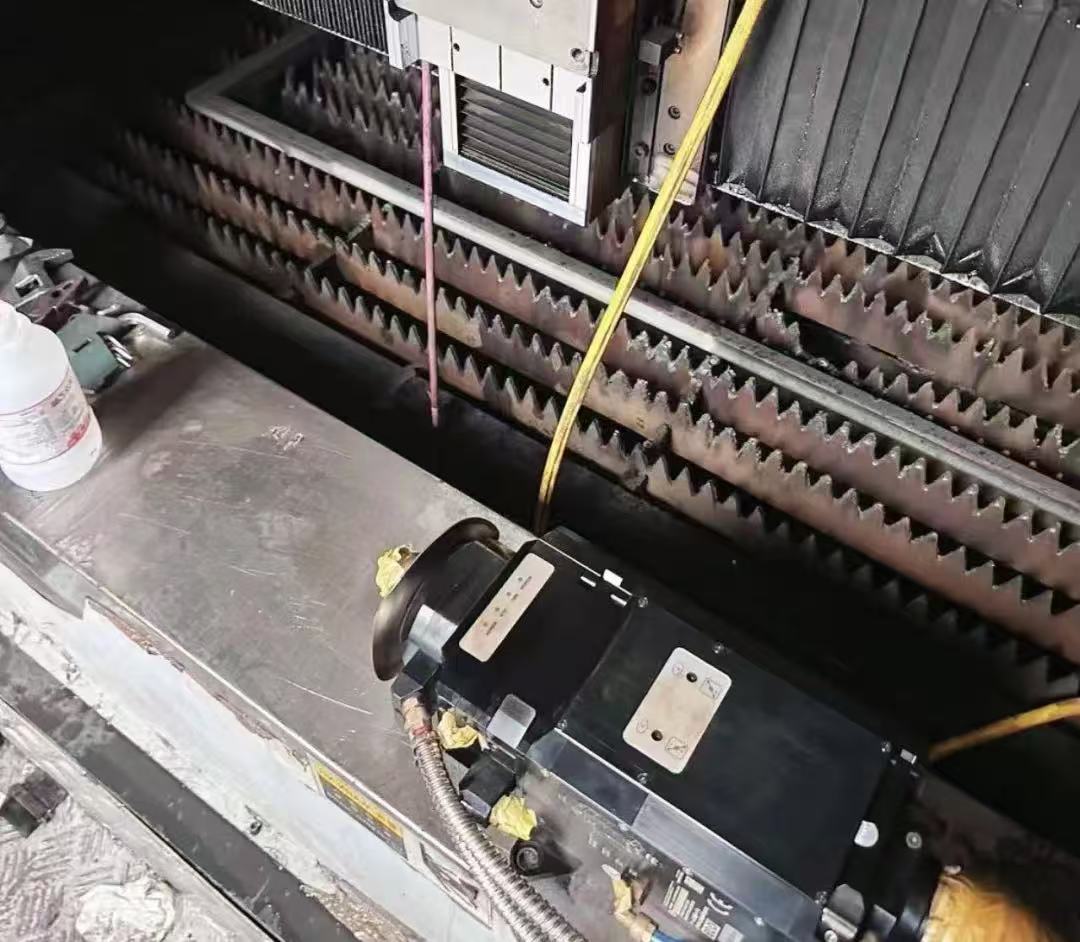

Solutions for Laser Cutting Head Condensation

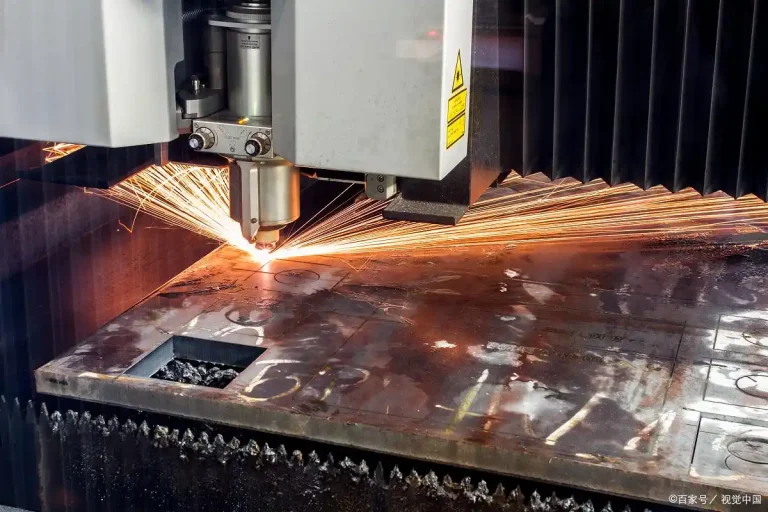

Laser cutting technology is widely adopted in modern manufacturing, where condensation on laser cutting heads is a particularly common issue. Condensation not only compromises cutting quality but can also damage equipment and increase maintenance costs. This article explores the hazards of condensation on laser cutting heads and proposes effective solutions.

Hazards of Condensation on Laser Cutting Heads

1.Optical Component Damage:

Condensation can form water films or droplets on the surfaces of optical components (such as focusing or collimating lens assemblies), impairing their optical performance.

Prolonged exposure to moisture may lead to corrosion, microbial growth, or damage to coating layers, thereby reducing the service life of these components.

2.Reduced Cutting Quality:

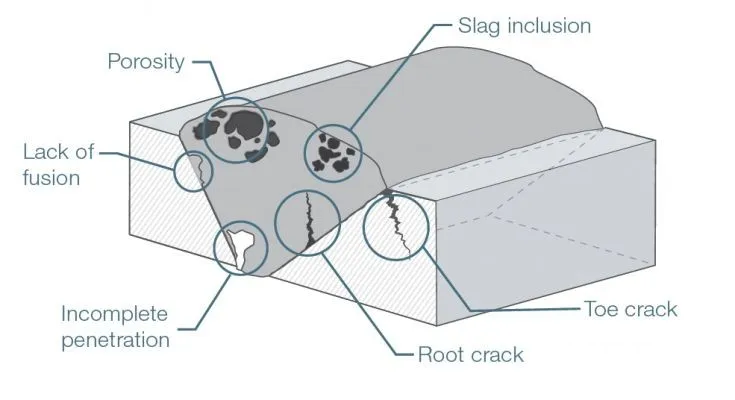

Moisture affects the transmission and focusing of the laser beam, leading to unstable cutting quality. During the cutting process, issues such as uneven cut edges, widened kerfs, or incomplete penetration may occur.

3.Equipment Malfunctions and Downtime:

Moisture ingress into the electrical components and control systems within the laser cutting head may cause short circuits or equipment shutdowns, impacting production efficiency and increasing production costs.

Solutions for Laser Cutting Head Condensation

1.Keep the cutting environment dry:

Use dehumidifiers or air conditioners to control humidity within the workshop, maintaining it within a reasonable range (typically between 40% and 60%). Avoid operating equipment in high-humidity conditions, especially in the morning or on rainy days.

2.Using Dry Air:

Ensure the air supply to the laser cutting machine is dry. If using compressed air, ensure it undergoes drying treatment. Regularly inspect and replace air filters and drying equipment to ensure they function properly.

3.Check the cooling system:

Ensure the cooling system is functioning properly to prevent excessively low coolant temperatures. Adjust the chiller’s high-temperature water setting appropriately (set to 28°C in summer). Inspect the cooling pipes for leaks and repair or address any issues promptly.

Conclusion:

By implementing the above measures, you can effectively reduce or prevent condensation issues on the laser cutting head, ensuring the equipment operates normally and maintains cutting quality.

If the problem persists, it is recommended to contact the equipment supplier or a professional technician for a thorough inspection and resolution.

We hope this article helps you address condensation issues on laser cutting heads, thereby improving equipment efficiency and cutting quality.