Laser welding is a field of metal processing technology using lasers, and is used in a wide variety of industrial fields such as automobiles, precision equipment, electrical appliances, aerospace, and medicine. This time, I will introduce the basic matters of laser welding, which is used especially in the sheet metal processing field, by selecting from the many uses of laser welding.

Principle of laser welding

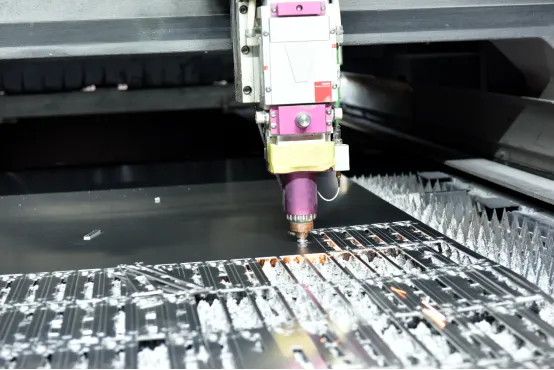

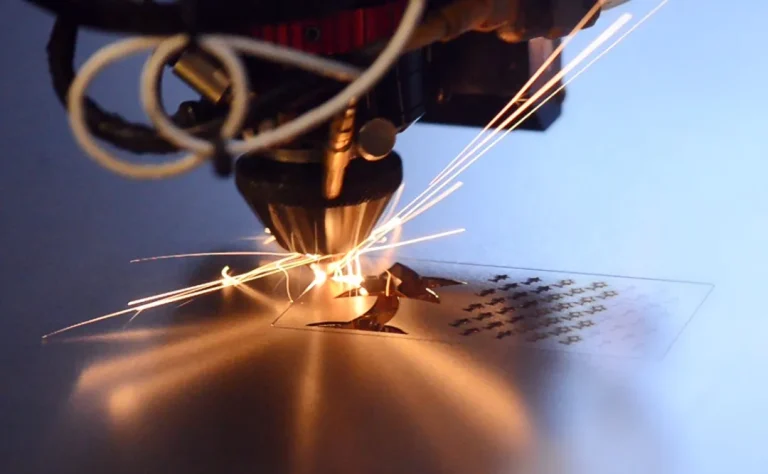

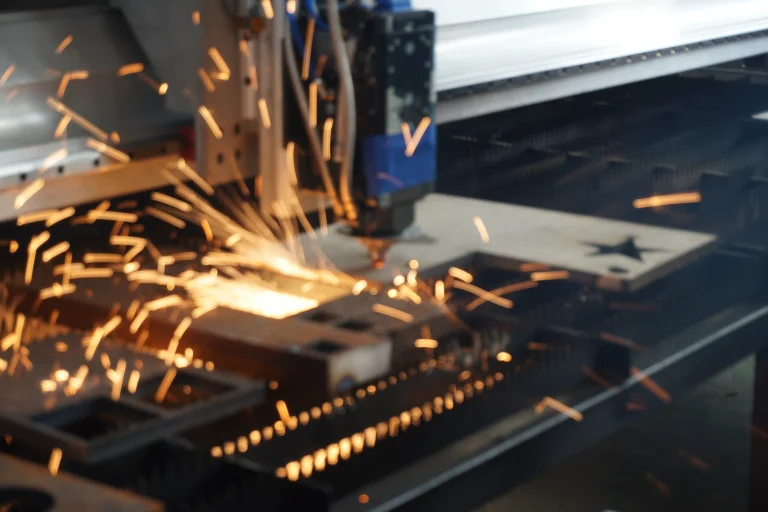

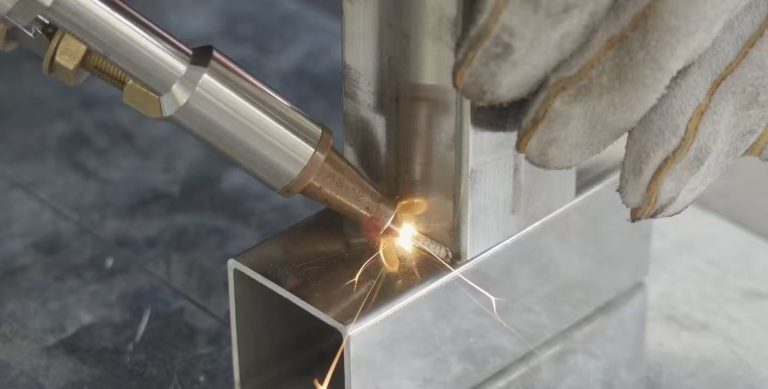

In laser welding, a laser oscillator is used to generate a laser light that becomes a heat source, expand it, and transmit it using an optical fiber that first delivers the light near the workpiece. A laser processing head is required at this stage. The laser processing head is equipped with a lens inside and concentrates the transmitted laser light into a state suitable for processing. By concentrating the light with the help of the lens, the light energy can be concentrated in a small area, and thus a higher energy for melting the metal can be obtained. In order to prevent oxidation of the molten metal, shielding gases such as argon and nitrogen are usually blown while welding.

Types of laser welding

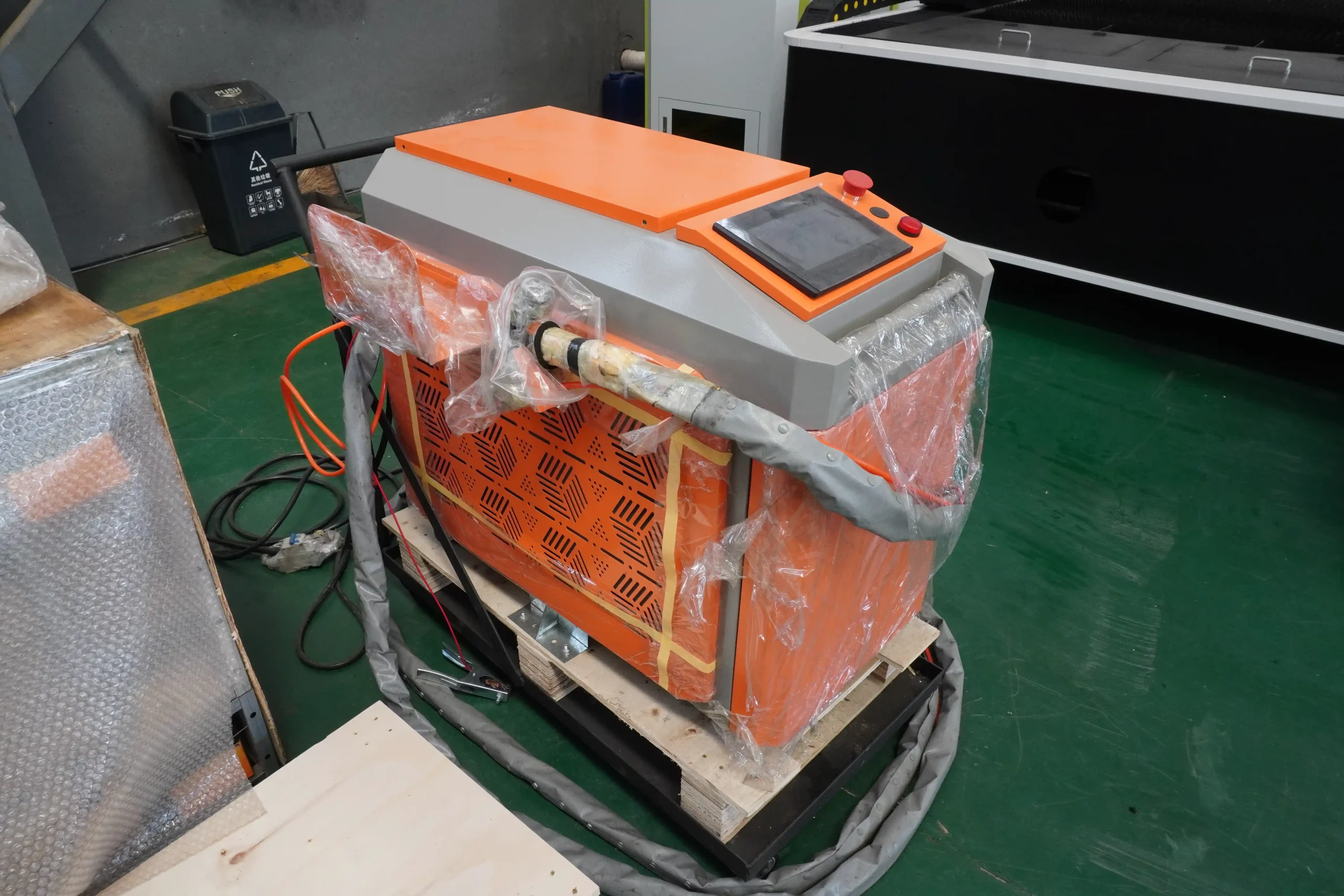

Types of laser welding suitable for hand welding for sheet metal processing. Since the 1990s, portable laser welding machines using YAG lasers have been the first to be popularized in Japan. Since then, the Japanese sheet metal industry has long believed that “laser welding machine = YAG laser,” but in recent years, fiber lasers have become the mainstay of portable laser welding machines, following the introduction of fiber laser welding machines in the mid-1910s. In addition, there are also portable welding devices utilizing disk-type lasers.

Hand welding with fiber laser welding machine

- YAG Laser Welding

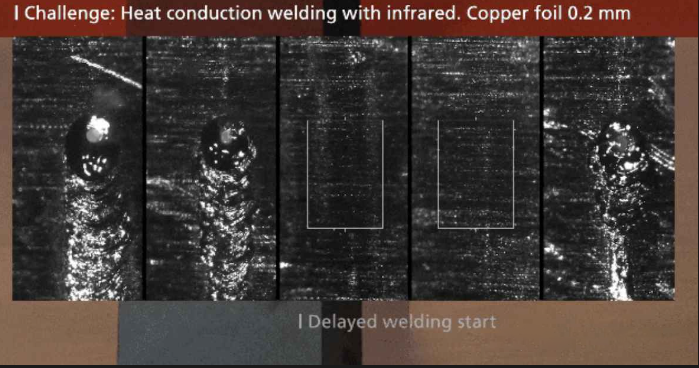

YAG is a crystal called Yttrium Aluminum Garnet, and YAG lasers generate laser light by shining an intense light into the YAG crystal. YAG laser light has a wavelength of 1064nm, which is easily absorbed by metals, and therefore melts metals with less energy, which is suitable for laser welding. On the other hand, in order to generate laser light, it is necessary to flash the flash lamp, and because it generates a lot of heat, it is necessary to use a chiller to cool the oscillator to the welding torch, so it consumes a lot of electricity, and the energy used for the process is less than that used for electricity, and therefore there is a problem of not being able to weld. The burden of maintenance costs for consumables such as cooling water and lamps is also large, which can be considered a major disadvantage in use.

- Fiber laser welding

Fiber laser is a laser that uses an optical fiber to expand and transmit the generated excitation light, and has a wavelength of 1070nm that is easily absorbed by metals. Among many lasers, the energy density is particularly high, and it is easy to concentrate the beam, and the ability to deep-melt metals is one of its major advantages. Compared with the YAG laser, it has many advantages such as deep melting, low operating cost, and almost no trouble or cost for adjustment and maintenance, and its popularity is accelerating in recent years. Although fiber lasers are characterized by high power and high efficiency, in hand welding of sheet metal, if the power is too high, it can be dangerous for the operator, so the power is usually limited to about 1kW when making products. When pursuing higher power and greater depth of weld penetration, the use of mechanical and robotic welding can be investigated.

- Disk Laser Welding

The disk laser is a laser that uses a disc-shaped YAG crystal to amplify the generated excitation light and then transmits it using an optical fiber. Since Germany’s Crydom has succeeded in realizing high power and stabilization, it has been widely used as an industrial laser, and in recent years its possibilities have been re-examined, and the development of new applications has been actively pursued. In Japan, there is no single machine capable of hand welding with a disk laser, but users of Crydom’s laser cutting machine can optionally introduce a torch for hand welding.

Advantages and disadvantages of laser welding

Laser welding used in sheet metal processing has the following characteristics compared to TIG welding, which was widely used in the past.

Advantages:

- Less heat distortion even for thin plates

TIG welding, due to the shallow penetration and the large heat-affected layer, results in high welding line energy on the metal and high heat distortion of the product. The handling of the resulting heat distortion is highly dependent on the skill of the craftsman, and this is the most difficult aspect of TIG welding. On the other hand, in laser welding, it is a concentrated laser that melts the metal by concentrating higher energy in a smaller focal point, so the weld penetration width is finer and the heat-affected layer is smaller, and therefore less likely to produce heat distortion. In addition, the “pulse oscillation” in which the laser is turned on and off repeatedly and frequently, melting and solidification are repeated several to dozens of times per second, so that distortion is suppressed even more.

- Ensuring adequate strength of the weld portion

Laser welding has a thin weld path, which is sometimes feared to be insufficiently strong, but the weld penetration is deeper, so the interior has sufficient strength compared to the exterior. The alloy portion that temporarily melts and solidifies in laser welding is small, so it will not break, and in strength tests conducted at industrial test sites, it has been confirmed that it has strength that exceeds that of TIG welding.

- Reduction of processing time

Laser welding has a low welding line energy and is less prone to distortion, thus dramatically reducing the number of hours required to eliminate distortion. In addition, since laser welding is basically a base material welding, it is possible to eliminate the need for grinding of weld protrusions. Also, as long as the processing conditions are favorable, weld burns are virtually non-existent, so it is possible to reduce the electrolytic grinding process. This reduces the number of processing hours, which used to be laborious, and contributes to increased productivity and reduced manufacturing costs.

- Easy management and operation of welding conditions

The laser welding machine also has a model that can be called up after the welding conditions are registered as a method, so it can be said that the ease of managing and reproducing the welding conditions is one of its major advantages. In this case, if a skilled person gives the conditions, it is easy for a non-skilled person to reproduce the processing conditions of the skilled person. As a result, if a non-skilled person can also be in charge of thin plate welding, the skilled person can concentrate on high value-added work, which contributes to the overall productivity of the welding process.

Disadvantages:

- Weakness in seam handling

Laser welding has the property of melting metal by concentrating laser energy at a very small focal point of about φ0.1 to φ0.6mm, and because of this property, it has the weakness of being unable to weld if there is a gap. In the case of a model with a spot diameter of φ0.1mm, if there is a gap of 0.1mm, the laser will pass through the center and it will not be possible to weld, so it is necessary to take measures such as improving the precision of the bending process and installing fixtures.

- Not good at overlay welding

Laser welding is good at base material welding, but not at overlay welding. In addition to the fact that the laser energy may not reach the base material at the point where the electrode melts, it is also difficult to align the weld point, the electrode, and the focal point precisely, and it may not be possible to ensure sufficient strength. When the drawing indicates cladding, it is necessary to examine whether laser welding should be used, but when laser welding is desired to ensure strength and aesthetics, it is better not to include cladding instructions.

- Safety measures required

Since the use of a laser can lead to serious accidents if it is used incorrectly, all laser products have safety-related specifications in the JIS standard “Safety Standard for Laser Products”. All hand welders using lasers are categorized as “Class 4”, the highest level of danger, and manufacturers take various safety measures. Please be sure to follow the specifications and operating instructions for proper use, such as setting up a laser management area, using welding masks/goggles for laser welding, using portable torches with safety devices, and properly managing the keys to the equipment.

Know-how of laser welding

Laser welding can realize both welding strength and aesthetics, and is a joining method with more advantages such as low distortion welding of thin plates and easy condition management, but on the other hand, it also has drawbacks such as poor seam handling ability and ineptness at overlay welding. Please pay attention to the following points for the know-how to utilize laser welding skillfully.

- Improve the accuracy of the bending process, set up fixtures, and weld after creating a seamless condition

- If you ask a skilled person to provide the processing conditions and register the method in advance, it will be easy for a non-skilled person to reproduce the process.

- If you change the processing method to laser welding without changing the drawings based on the previous processing method, such as TIG welding, it will be difficult to complete the process successfully. In some cases, it is possible to consider studying design changes.

- If you want to maximize the advantages of laser welding, such as strength and aesthetics, it is recommended that you design with laser welding in mind from the design stage.

Summary

The greatest advantage of laser welding is the ability to weld thin plates with low distortion. It can also be welded by unskilled people, and thus has the potential to significantly improve the welding process, which used to rely on the skills of craftsmen. As long as the disadvantages are properly understood and dealt with, the advantages are all that remain. Let’s make the most of the advantages of laser welding.