With the continuous advancement of industry, laser cutting technology has found widespread application across various mechanical manufacturing sectors, including construction machinery, locomotive manufacturing, and agricultural and forestry machinery. To ensure seamless welding of certain workpieces, higher processing requirements are imposed, necessitating that the cut surfaces possess a specific bevel angle.

When performing bevel cutting, laser cutting machines must precisely control the oscillation angle of the cutting head. Through years of technological innovation and market application in fiber laser cutting machines, Glorious Laser has achieved increasing maturity in bevel cutting processes.

Types and Advantages of Bevel Cutting

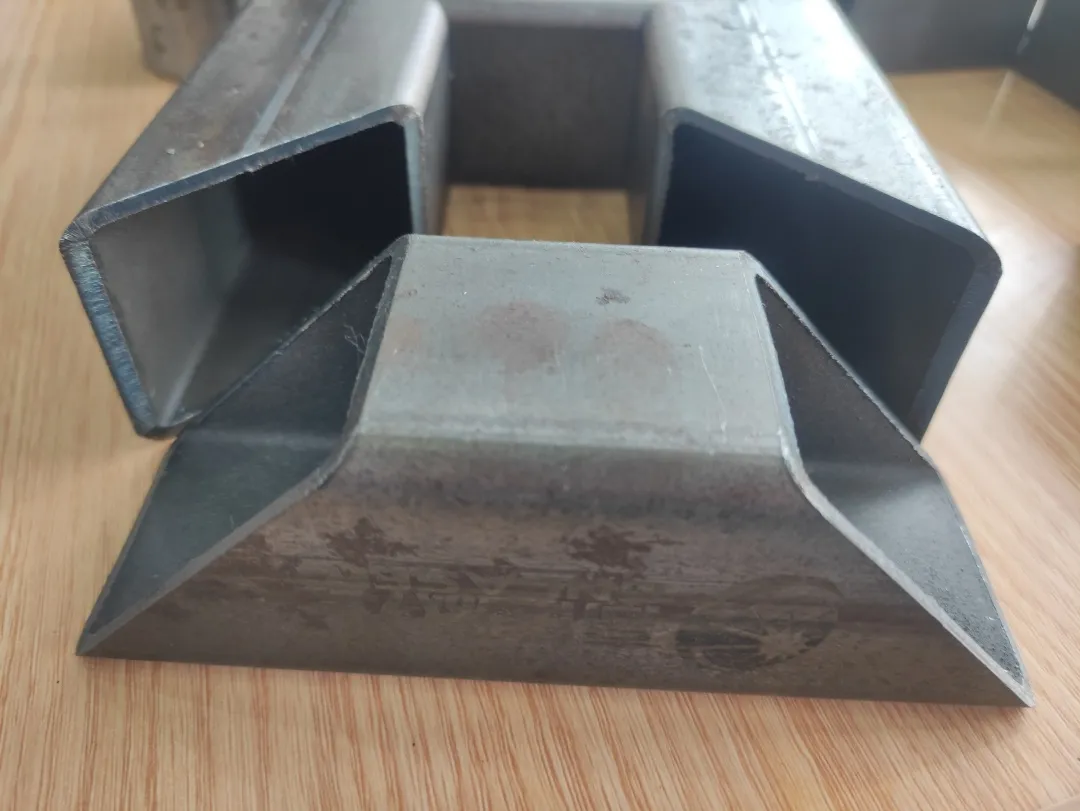

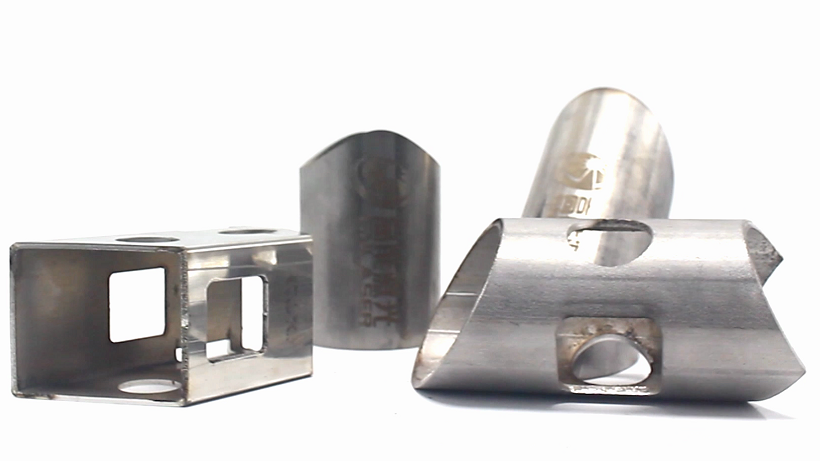

Glorious Laser’s bevel cutting technology is applicable for both plate and pipe cutting, fulfilling the one-step forming requirements for various bevel types including V, X, and Y. Compared to traditional multi-step processes like cutting and milling, it significantly enhances efficiency while delivering high-quality beveled workpieces with superior dimensional accuracy.

1.Enhanced processing efficiency.

Compared to traditional methods, laser cutting machines achieve bevel cuts in a single pass without requiring secondary cutting or grinding, boosting efficiency by over 75%.

2.Improved bevel surface quality.

Traditional machining of arc-shaped bevels yields poor surface quality, making them unsuitable for automated welding. Laser cutting machines produce bevels that are ready for direct welding.

3.Consistent batch processing quality.

Traditional cutting methods suffer from inconsistent bevel quality and low efficiency due to operator fatigue. Laser cutting enables small-scale prototyping, followed by immediate batch production upon approval. This ensures precise bevel dimensions and continuous cutting for workpieces.

4.Reduce beveling processing costs.

Traditional beveling methods require extensive manual grinding. Laser cutting machines enable batch production of beveled edges, effectively reducing labor costs and time investment.

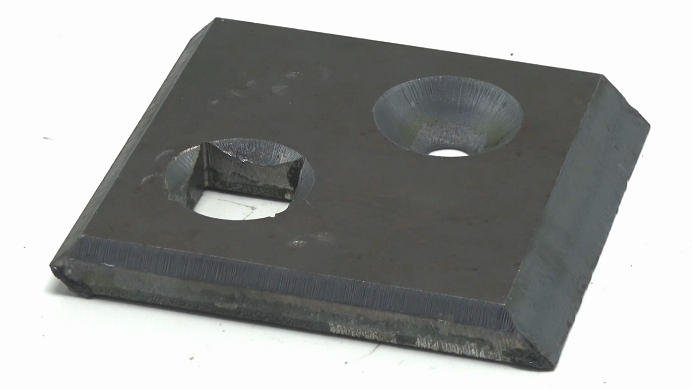

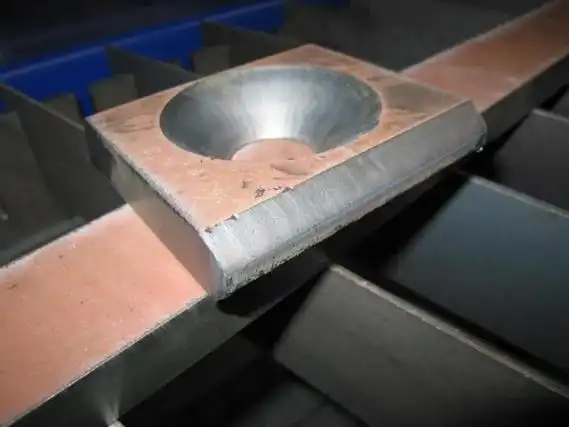

Through the bevel cutting process, the workpiece’s cut surface is smooth and flat, enabling seamless butt welding between components, which fully meets the requirements for bevel welding of the workpiece.

Bevel Cutting Demonstration

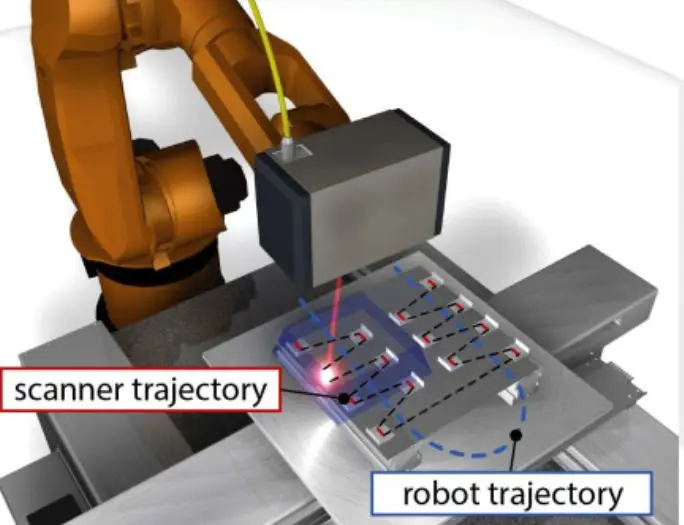

The Glorious laser bevel cutting system features a 45° oscillating cutting head with superior performance. Controlled by an advanced five-axis CNC system for machine tool interpolation, it enables bevel cutting of workpieces within a 0°-45° range. The dedicated 3D cutting head incorporates automatic focusing functionality, dynamically adjusting the focal point during bevel cutting based on material thickness and angle variations to meet cutting process requirements.

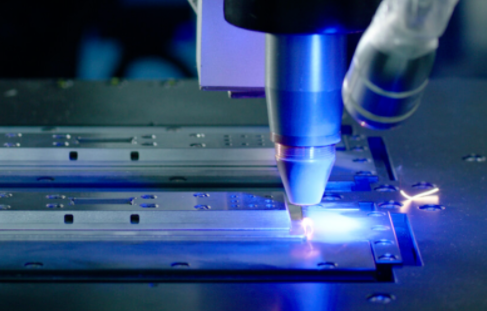

1.Plate bevel cutting

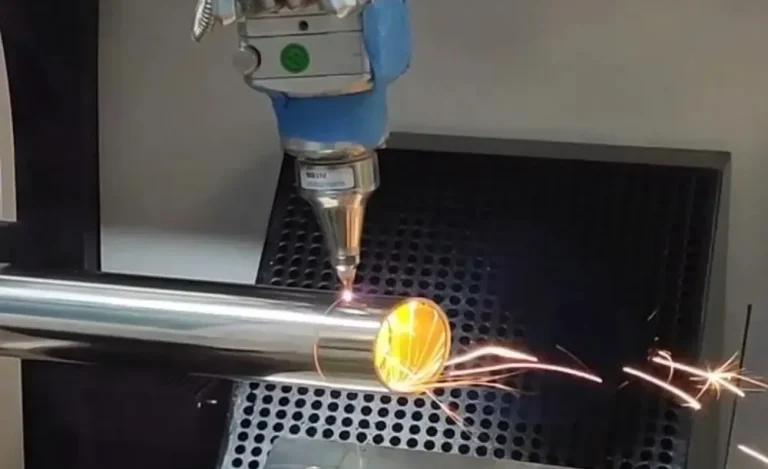

2.Pipe Bevel Cutting

The Glorious will actively support the development needs of more customers, continuously optimize and upgrade our offerings, and proactively address the increasingly sophisticated metal processing demands of the market. We will persistently develop new laser processing technologies, driving the metal processing industry toward greater efficiency, intelligence, and precision with higher-quality products.