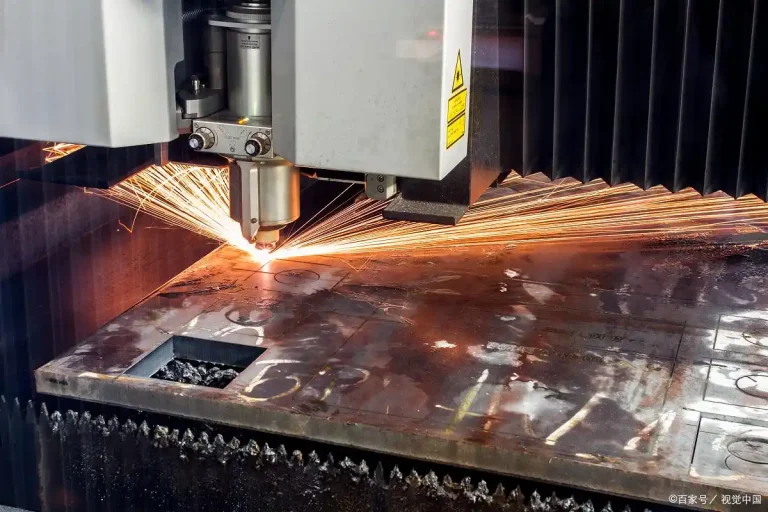

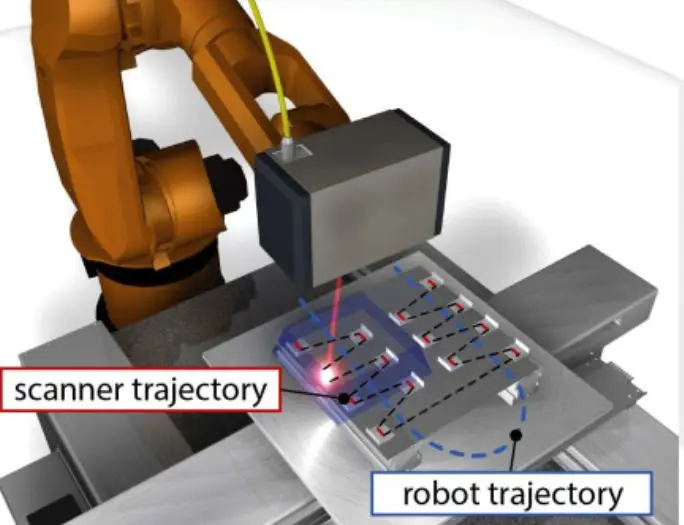

1.laser Flying welding

Laser flight welding integrates the advantages of remote welding, vibrating mirror and manipulator, with professional graphic processing software, so as to realize three-dimensional space instantaneous multi-track welding.

Mainly used in:

Automobile body, seat and commonly used auto parts and other products, material can be applied to various types of steel, cold rolled plate, aluminum alloy and other commonly used materials, can also be applied to composite materials, alloy materials such as magnesium aluminum alloy.

Laser Flying Welding Advantages:

①Any weld pattern

②Any seam orientation

③User-defined seam/point distribution

④Optimized force distribution

⑤High-speed spot, seam, stack, butt, fillet and lap welding

⑥Real-time synchronization of weld head and robot speeds up the laser welding process

⑦Smaller footprint

⑧Reduced maintenance and logistics costs

2.laser Wobble welding

A laser welding method with double-wedge laser oscillation, realized by configuring a special wobble oscillation module on the welding head. The focused spot is moved by the welding head to produce a spiral weld. The main applications are: welding of hinges, heat exchangers, tubular heat exchangers, thick tubes for oil and gas, flanges and aluminum alloys, among others.

laser Wobble welding Advantages:

①Reduction of pure laser welding defects such as porosity, cracks, and excessive product fit-up gaps

②Increase the strength of the weld seam and obtain a more perfect weld path.

③Brazing is that the base material does not melt, only the brazing material melts.

④Small brazing distortion, smooth and beautiful joints, suitable for welding precision, complex, different material components

⑤Small heat-affected zone, high compressive strength

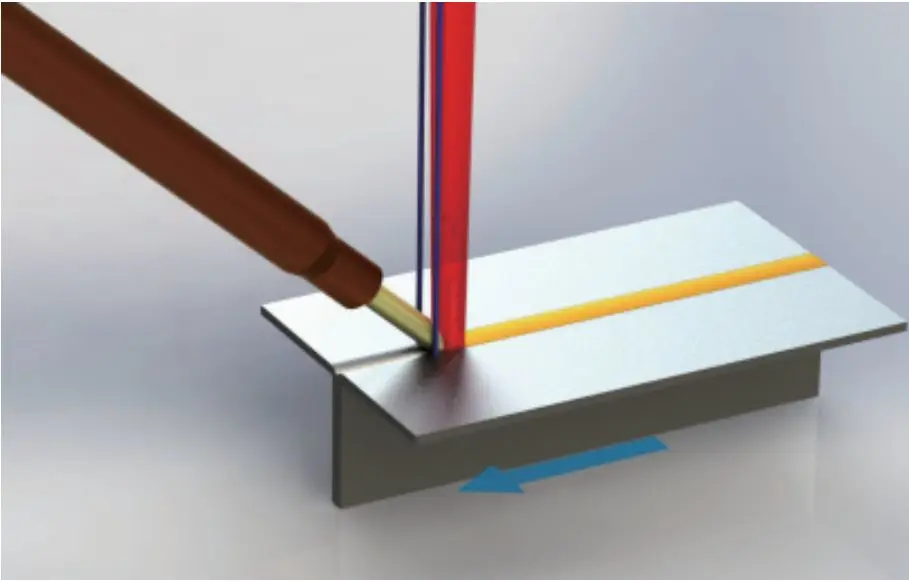

3.Laser brazing

Laser brazing refers to the use of filler metal with a lower melting point than the base material, the brazing material is heated to a temperature higher than the melting point of the brazing material and lower than the melting temperature of the base material, and the liquid brazing material is used to wet the base material, fill the gap between the joints and diffuse with the base material to realize the method of joining the welded parts. Mainly used in aluminum body frame structure welding, such as the roof and case surround connection, doors and other products.

Laser brazing Advantages:

①Reduction of pure laser welding defects, such as porosity, cracks, and excessive product fit-up gaps

②Increase the strength of the weld seam and obtain a more perfect weld path.

③Brazing is that the base material does not melt, only the brazing material melts.

④Small brazing deformation, smooth and beautiful joints, suitable for welding precision, complex, different materials composition components

⑤Small heat-affected zone, high compressive strength

4.Laser Filler Welding

Laser fillet welding is a method of forming a weld by melting the base material with a filler metal of the same or similar material as the base material and condensing it to form a weld. It is mainly applied to: full body structural parts of vehicles and automotive parts and components.

Laser Filler Welding Advantages:

①Reduction of pure laser welding defects such as porosity and cracks

②Increased weld product margins, allowing slightly larger weld product gaps

③Welding of the base material is melted and the weld strength is stronger than the base material.

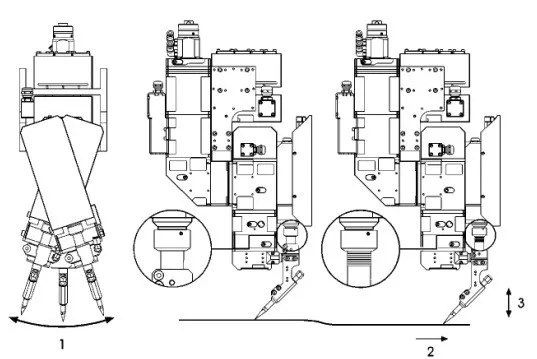

5.laser Oscillating brazing

Combines beam forming and weld tracking functions in one machine with ALO3. The filler wire can be used as a mechanical sensor. It is mainly used for white body laser welding, mainly including roof lid laser brazing and trunk lid laser brazing, and automotive parts brazing. The fluctuation of parts and fixture errors, often add a lot to the difficulty of laser brazing, resulting in laser welding debugging process is exceptionally difficult, but the pendulum brazing it can effectively regulate its own welding direction, weld tracking and focal length automatic compensation function, can make the laser beam easy to guide, focus, to realize the transformation of each direction, high degree of automation, welding speed, high efficacy, so that it can maintain the quality of the weld.

laser Oscillating brazing Advantages:

①Welding seam tracking, real-time judgment of workpiece welding seam trajectory.

②Adaptive adjustment of welding trajectory in XYZ direction according to the deviation of different workpieces to obtain good welding quality.

③Improvement of product weld consistency

6.Triple Spot Brazing

Adding a double spot module in the lens, in which when welding, one beam is distributed into three beams by the triple spot module in the brazing optics, provides a solution for brazing hot-dipped galvanized steel sheets. It makes the weld more flat and no cracking. Mainly used in: aluminum alloy brazing of white body, roof lid laser brazing and luggage compartment lid laser brazing, and automotive parts brazing.

Triple Spot Brazing Advantages:

①More stable and reliable brazing process

②Faster speeds

③Higher strength

④Higher exterior surface quality for hot-dip galvanized sheet welding

⑤In-line cleaning process

⑥Dynamic energy adjustment

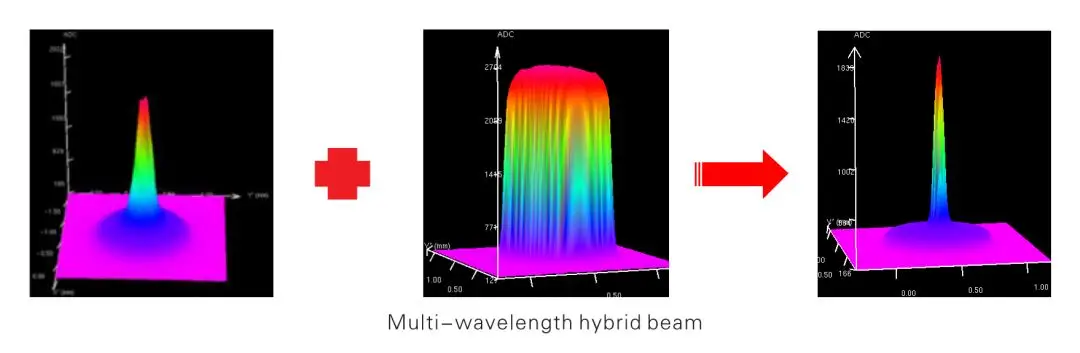

7.Multi-wavelength composite welding

Multi-wavelength composite welding is the welding process pioneered by Lianweng Laser, which is made by superimposing two different wavelength lasers so that the axes of the two laser beams overlap in space. The primary wavelength laser mainly carries out the welding, while the secondary wavelength laser mainly preheats the welding wire and the base material and reduces the cooling speed of the metal liquid in the welding molten pool. It is especially suitable for aluminum alloy, magnesium alloy, copper alloy and so on.

Multi-wavelength composite welding Advantages:

①Reduced porosity

②Increased stability of welded joints and increased welding efficiency

③Effective relief of thermal stress can reduce cracks, improve the strength of the weld to obtain a more uniform appearance of the weld.

The above is the process of laser welding, our company is specialized in the production of laser welding machine manufacturers, any related problems can contact us to communicate.