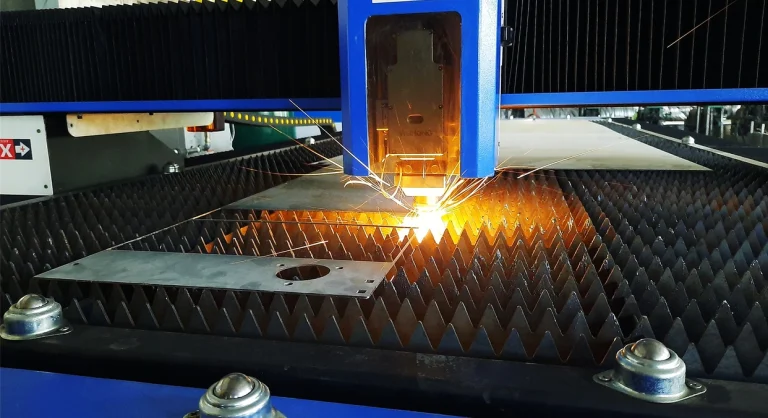

The problem of dents in mild steel during laser welding is closely related to the assembly gap. The assembly gap, also known as the counter gap, is the gap between two weldments at the weld. The size of this gap directly affects the formation of the weld and the quality of the weld.

First of all, too small an assembly gap may lead to a weld that is not easy to weld through, while too large an assembly gap will increase the difficulty of welding and require more filler material, which will affect the welding progress and may increase the welding stress, which is prone to welding deformation. Excessive assembly gap will lead to increased filling of the molten pool metal, increased depth of fusion and wider heat affected zone, thus affecting the quality of weld formation.

The problem of denting in laser welding of mild steel can be solved in the following ways:

1.Control of assembly clearance: Maintaining proper assembly clearance is the key to preventing denting. Usually, for different joint forms, the maximum clearance allowed for laser welding is 0.05 times the plate thickness, and the maximum deviation of the laser beam from the gap match is 0.5 times the spot diameter .

2.Optimize welding parameters: including laser power, welding speed, focus position, etc. to ensure the stability of the molten pool and the uniformity of the weld .

3.Surface treatment of workpiece: Thoroughly clean the surface of the workpiece before welding to remove oil and pollutants in order to minimize the generation of spatter and porosity, which can lead to craters and blown spots on the surface of the weld, affecting the mechanical properties of the weld.

4.Use of oscillating welding technology: By changing the laser scanning method, the temperature uniformity of the weld is improved and localized overheating is reduced, thus reducing the occurrence of dents.

5.Adjustment of spot energy distribution: Use of non-Gaussian distributed beams, such as ring + center beams, reduces high temperature vaporization in the center area and helps to reduce splattering and denting .

6.Use of short wavelength lasers: Short wavelength lasers, such as blue light, have a higher metal absorption, which reduces spattering and helps to improve the quality of the weld.

7.Welding Equipment Maintenance: Regular maintenance and calibration of the laser welding equipment ensures the stability and accuracy of the laser beam and helps to improve the quality of the weld.

Through the above measures, the denting problem during laser welding of mild steel can be effectively controlled and the quality of welded joints can be improved. In the actual production, according to the specific welding requirements and material characteristics, should be based on the specific welding requirements and material characteristics, meticulous process testing and optimization, in order to achieve the best welding results .