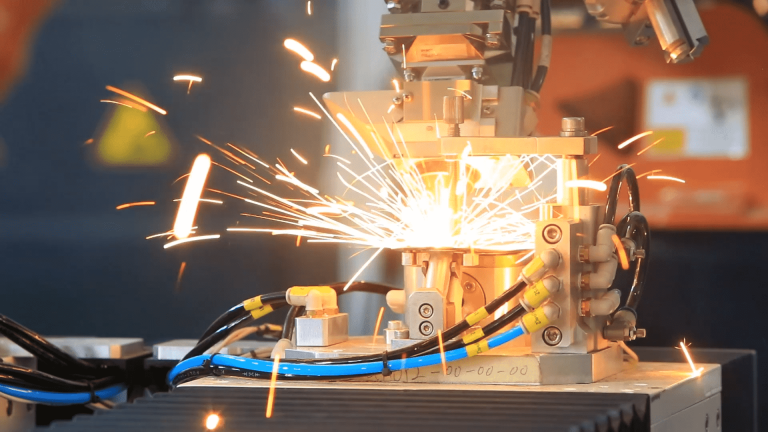

In the ever-evolving landscape of industrial manufacturing, achieving high efficiency and precision in cutting carbon steel has become a critical challenge for many enterprises. Carbon steel, an iron-carbon alloy with a carbon content ranging from 0.0218% to 2.11%, is widely used across various industries due to its hardness and strength. However, traditional cutting methods often struggle to balance speed and accuracy. Fiber laser cutting machines have rapidly become the mainstream choice in the market, particularly suited for precision processing of thin carbon steel sheets.

Carbon steel is a ferrocarbon alloy with a carbon content of 0.0218%~2.11%. Generally, it also contains a small amount of silicon, manganese, sulfur, phosphorus and other elements. The higher the carbon content in carbon steel, the greater the hardness and the higher the strength, but the lower the plasticity. With the increasingly fierce competition in the industry, how to improve efficiency and reduce cutting processing has become a concern for most users. With the advantages of fast cutting speed, small material deformation and high processing accuracy, the fiber laser cutting machine has quickly become the mainstream of the market.

Advantages of thin plate precision laser cutting machine for cutting carbon steel:

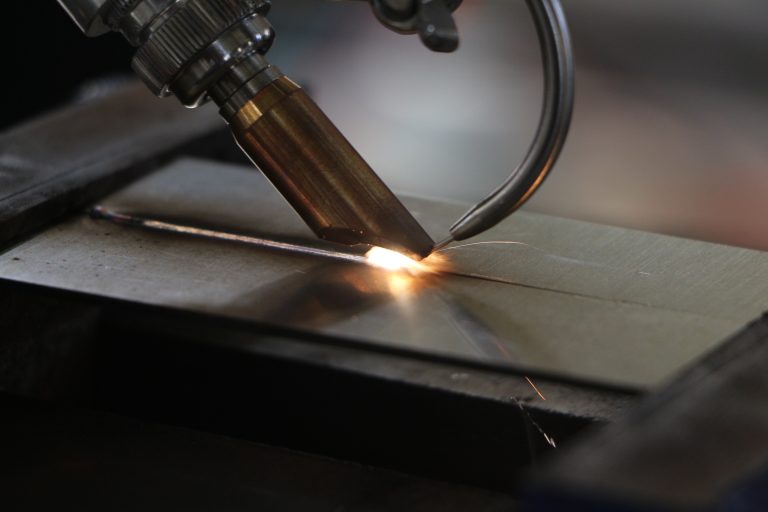

- High cutting accuracy, can reach ±0.01mm, good quality, small cutting seams, small deformation, smooth, flat and beautiful cutting surface, no follow-up treatment required;

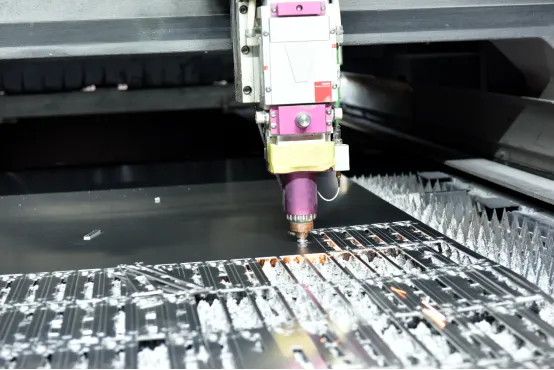

- Fast cutting speed, continuous and fast curve cutting function and shortest processing path optimization function greatly improve work efficiency;

- High stability, stable output power of the equipment, long-term continuous operation, long-term laser service life, simple maintenance;

- Powerful operation function, can design all kinds of graphics and text for instant processing at will, and can realize simultaneous output of a variety of working methods such as engraving, cutting, and micro-hole punching of workpieces.

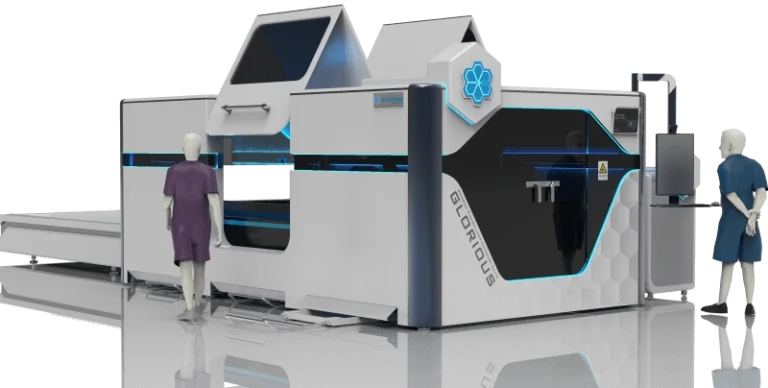

For carbon steel processing, the most important thing is to ensure the accuracy of the product, especially some hardware parts, because most of them are used in automobiles, ships, precision accessories and household appliances. Chuangheng Laser CX-CC6060L precision laser cutting machine is mainly aimed at high-speed laser processing of thin plates, and can efficiently cut carbon steel, stainless steel, copper, aluminum and alloy, titanium and alloy and other metal materials. The whole machine runs stably, and the repeated positioning accuracy is as high as 0.004mm, which is 20% more efficient than that of traditional machine tools. It is precision-machined with thin metal!

In conclusion, fiber laser cutting machines exhibit significant advantages in the precision processing of thin carbon steel sheets, including high accuracy, fast cutting speeds, stability, and versatile operation capabilities. For companies requiring high-quality and efficient production, selecting the right laser cutting equipment is crucial. The CH Laser CX-CC6060L precision laser cutting machine not only meets these needs but also enhances production efficiency and reduces post-processing steps, making it an ideal choice for modern manufacturing.