Discover the real cost of laser cutting: break down labor, machine maintenance, and setup time. Learn why prototyping is expensive and how smart manufacturing is reducing small batch costs. Get actionable insights for cost-effective sheet metal fabrication.

1.Laser processing costs are affected by the number of models and pieces processed

As mentioned in the introduction to bending, each process is made up of a combination of different subsections, and the overall cost of the process is the sum of the costs of the various processes involved in the product.

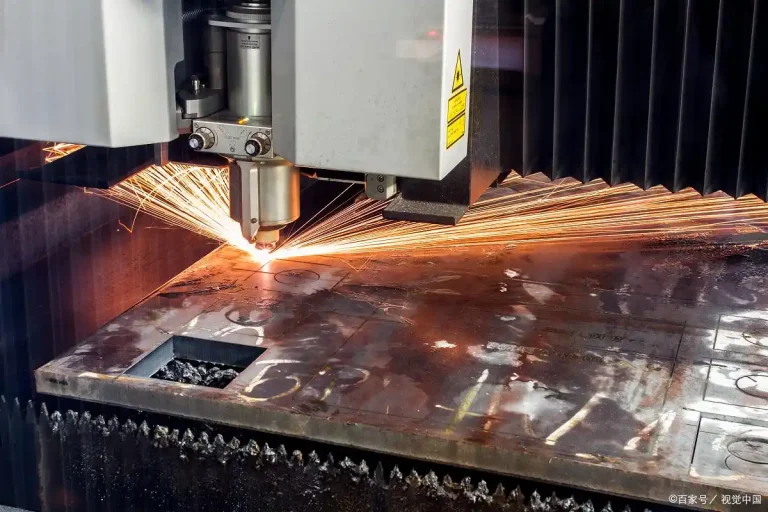

Since there is no tooling costs, the cost of laser processing, mainly by the cost of labor, machine operation and maintenance costs, and time costs of three components:

That is, laser cost = labor cost + machine operation and maintenance cost + time cost.

Labor costs are very low: due to the high degree of automation and simplicity of laser cutting machines, one person can usually operate a machine.

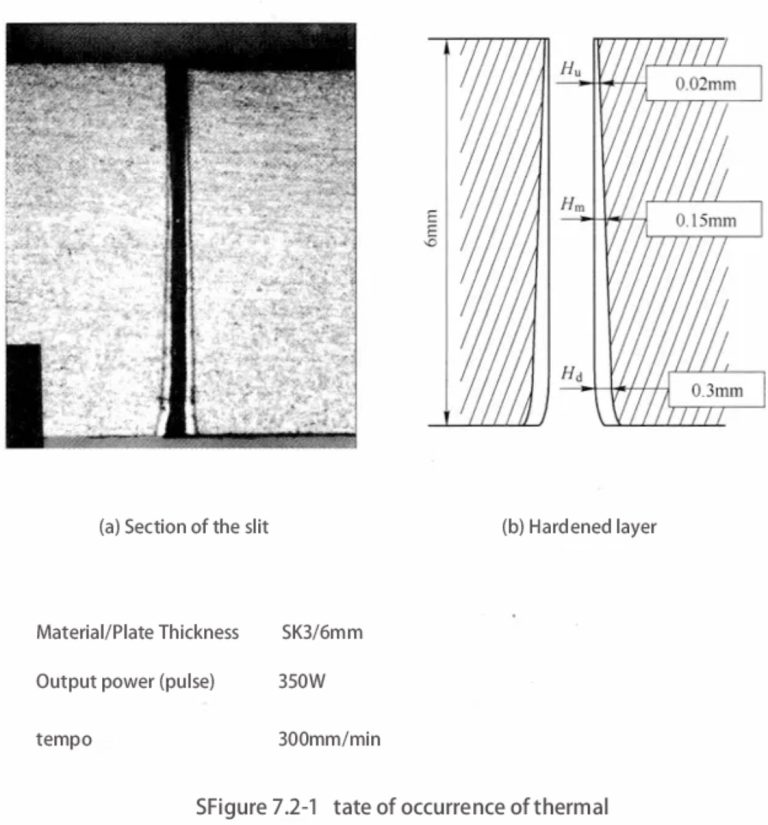

And machine operation and maintenance costs are fixed: equipment operation of electricity, cutting auxiliary gas energy costs, as well as protective lenses, cutting nozzles and other consumables such as wear and tear costs, are calculated according to the use of the cycle.

Only the cost of time is variable: the actual time cost of processing includes the cost of preparatory work such as nesting time, plate loading and unloading time, machine commissioning time (selection of parameters, positioning, etc.), and the actual cost of cutting consumed by the equipment for formal cutting/processing. Laser processing time cost = preparation time + actual cutting time.

The processing time cost of one piece is 20 seconds, if it is a batch piece, has been only processing this product, then we can do uninterrupted production, one minute to process 3, one hour to process 180, ten hours total can process 1800. However, if it is just a prototype, then the processing time is not much time we have to go to change the material to change the settings, the time spent during this period is sometimes even more than the time spent on cutting.

Therefore, the actual cost of processing time is affected by the number of models and pieces processed:

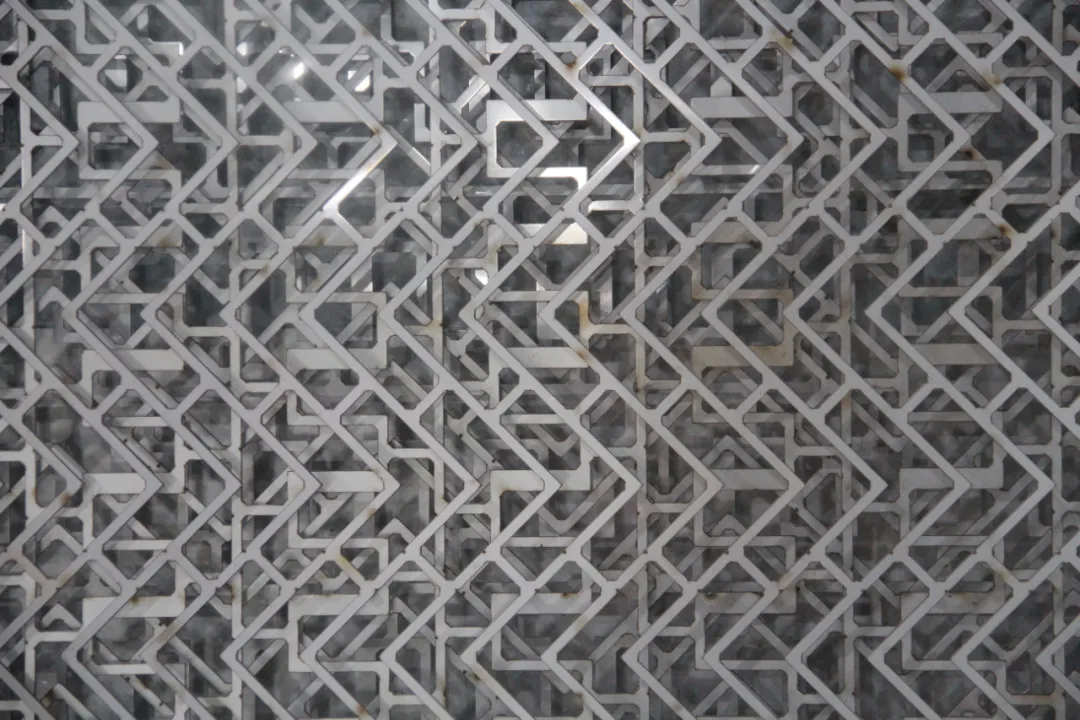

The more models – as a result of the need for multiple nesting sets, repeated loading and unloading, and constantly switching machine parameters, the time cost increases; the fewer the number of models, the lower the cost of time;

The more pieces – when the number of pieces is a lot, only need a layout nesting, a feeding, a tune machine parameters, can always be processed; when the number of pieces is very small, the workpiece is processed at once, and then change the material to change the parameters, in order to start processing another workpiece, the cost of time has increased dramatically.

2.Prototyping and small batch production have become the trend in today’s processing industry.

Why do most traditional factories like to take bulk parts? Just because batch parts can save a lot of costs in non-processing stages, such as the pre-preparation work mentioned earlier. When each production of products are sampling, each product requires a lot of preparation work in front of the production, and workers have been required to continue to learn, change their production methods and rhythms, and even prepare it longer than the production of it.

Can not achieve large-scale production, there is no way to borrow a larger batch to share the total cost of fixed costs, so that the unit cost of each commodity under the cost can not go down, the offer is naturally high, then compared to other factories have a small advantage.

Factories like to receive bulk parts, then sampling is not no choice? Of course not!

With the continuous development of the economy, people’s needs are gradually personalized, diversified, the market is changing rapidly, technology has been progressing, the product life cycle becomes shorter. Just like the current electronic products, from the previous ten years a new generation to the current annual new. Sampling and small batch demand is growing, mass production stockpiling has become a thing of the past, a small amount of diverse production is the development trend of our times.

Therefore, the future of sheet metal processing requires us to consider is no longer the number of single processing, but how in a small number of diverse production environment, through the industry intelligence, production automation, intelligence, and other ways to break through the traditional processing methods, so that the production efficiency of all aspects of the production efficiency up to go from the overall go to reduce the cost of production of the samples, and from which to squeeze out the profit. We are now building such a set of production process specifically for samples and small quantities, from the construction of online ordering and quotation platform, to offline digital management and information transfer, upgrading and iterative production process, etc., to continuously improve production efficiency and reduce production costs.

Laser processing high efficiency, simple operation, flexible production characteristics, is very suitable for sampling and small batch production.

It has no special skills in operation, mainly from the design of some of the specifications to see how to reduce production costs from the design, and to achieve the results they want.

In conclusion, laser cutting cost is heavily influenced by setup time and batch diversity—not just cutting speed. While prototyping remains costly, the future lies in smart factories with automated workflows, digital quoting, and lean production. Embrace small-batch agility to stay competitive in the era of rapid product innovation.