Laser welding is an advanced manufacturing technology with high precision and efficiency. However, for copper, the process is challenging due to the inherent properties of the metal. Copper’s low absorption of near-infrared laser light at room temperature, high thermal conductivity, and fluctuating absorption rates are all significant obstacles. In this blog post, we will delve into the difficulties of copper laser welding, the defects that result from these challenges.

High thermal conductivity and fast heat dissipation

Copper has an extremely high thermal conductivity of up to 401 W/(m*K), which not only facilitates rapid heat dissipation, but also complicates the laser welding process. This means that when the laser beam hits copper, most of the energy is lost to cooling rather than being used to weld the depth. For example, with an input power of 1,000 W, copper may consume 400 W, leaving only 600 W for welding, while steel may retain 920 W. To achieve a comparable depth of fusion, copper requires more than twice the laser power of aluminum and more than five times that of steel. High thermal conductivity can lead to a range of weld defects, including unfused and rough appearance at the macro level, as well as large heat-affected zones and degradation of properties at the micro level. While preheating is often necessary for low-density welding processes such as arc welding, high-density processes like laser welding require higher power to maintain stability.

High reflectivity, low absorption

The high reflectivity and low absorption of infrared lasers by copper is another obstacle. The widespread use of fiber lasers, especially in the 1030-1080nm wavelength range, results in only about 3% of the incident laser light being absorbed by copper at room temperature. This low efficiency requires higher power lasers for effective welding, which exacerbates instability in the welding process. Strategies to overcome this problem include optimizing laser parameters and exploring different wavelengths that may interact more favorably with copper.

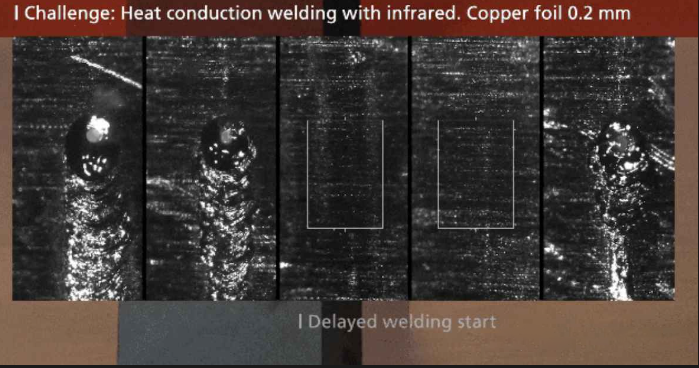

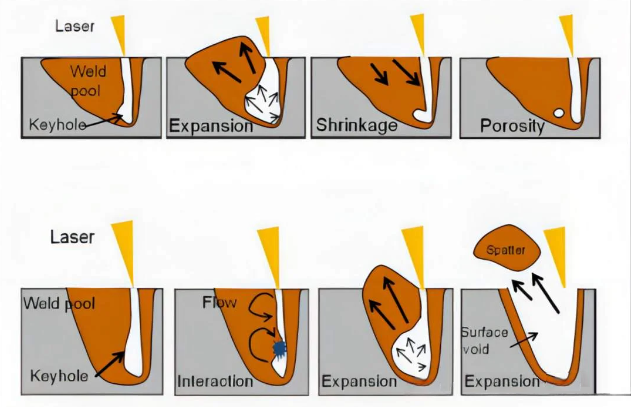

VARIABLE ABSORPTIVITY

The difficulty of laser welding is further increased by the fact that the absorptivity of copper varies dramatically during the welding process. At room temperature, the initial absorption of solid copper is about 3%, increasing slowly to about 8% at 1250K, an increase of only 5%. However, in the narrow temperature range of 1250-1350K, the absorption jumps to about 15% and the thermal conductivity drops dramatically from 330 W/(mK) to about 160 W/(mK). This drastic change leads to a significant increase in heat buildup, which results in defects such as spattering and porosity.

Copper laser welding presents unique challenges and requires specialized methods to ensure high quality connections. Significant fluctuations in high thermal conductivity, high reflectivity and absorption require the use of higher laser power and tight control of welding parameters. By understanding these challenges and implementing the solutions offered by LASERCHINA engineers, manufacturers can overcome the obstacles associated with copper laser welding and achieve reliable, efficient results. As technology advances, further optimization of laser equipment and processes will continue to increase the capabilities of copper welding in a variety of industrial applications.