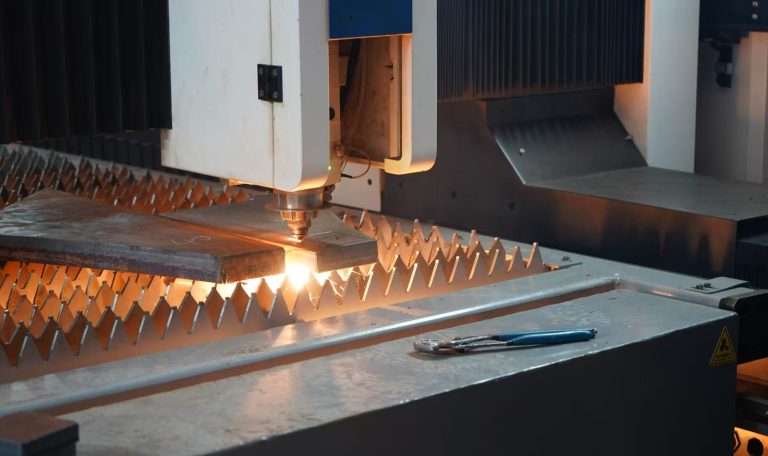

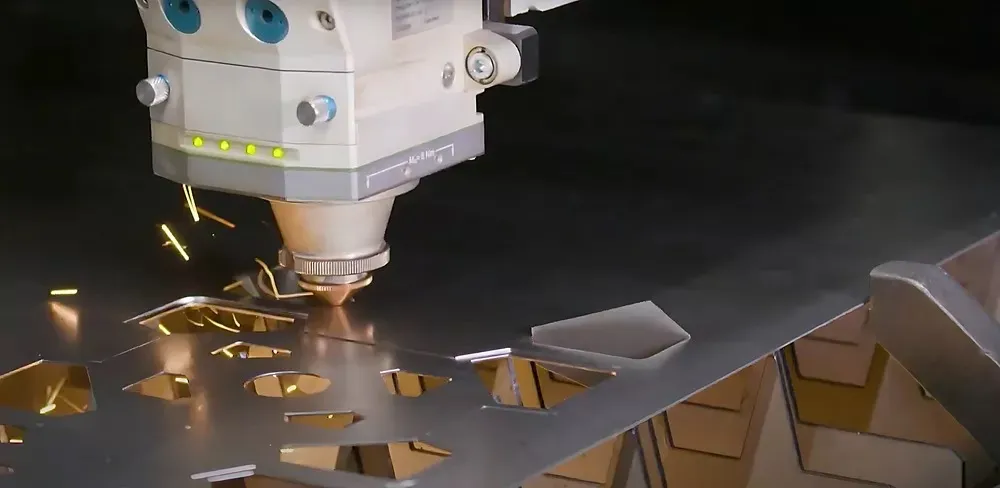

Modern fiber laser cutting is incredibly fast, but the process generates enormous kinetic energy, which can cause workpieces to tip over or scrap to splash, which in turn can interfere with the fast-moving cutting head – the most delicate part of the entire machine. If the inner contour waste cut in the previous process warps and falls to the surface of the plate, resulting in head bumping, the entire process can not be called stable.

To achieve a stable and controllable cutting process, three intelligent strategies must be satisfied: tool path planning should take into account the material utilization rate; the nesting scheme should be integrated with the requirements of the part orientation (such as the texture direction of the exterior parts or the fiber direction of the bent parts); and the optimal use of micro-connections (not only to meet the requirements of the subsequent processes for the cut finish, but also to facilitate the material separation and reduce the burr trimming).

Stable laser cutting ensures that the workpiece is securely positioned in the nest and that the inner contour scrap falls smoothly through the grid gap. Fiber lasers generate intense turbulence, and scrap trajectories are often difficult to predict. Today’s intelligent software does double duty – it holds the workpiece and guides the scrap safely out of the nest in the desired path.

The need for dynamic nesting

Today, the sheet metal working industry is generally challenged by a multi-variety production environment. Optimized nesting solutions often require the integration of diverse parts from multiple orders, and crucially – the mix of production tasks is always in dynamic flux. While programmers can invest a significant amount of time in static nesting optimization (including material utilization and cutting path planning), this time cost is not infinitely consumable.

What is the actual reuse rate of these nesting solutions, given the characteristics of the customer’s needs? Some orders may go into production frequently, but if the nesting includes a batch of low-volume “one-off” parts, is this optimization still worthwhile? As a result, modern programmers are relying more and more on dynamic nesting solutions automatically generated by software.

These programs can automatically identify process constraints (such as part positioning to ensure that the fiber direction of the blank meets requirements), set safe travel parameters for the cutting head (maximum translation distance before the Z-axis lifts the tool), and intelligently evaluate the application of micro-joints (which can be added to long, narrow parts to prevent tipping, but can be eliminated for parts spanning multiple grids, while simplifying stock splitting and avoiding burrs).

These features have become the building blocks of modern nesting software. It’s interesting to note that software technology has made breakthroughs in recent years – veteran laser programmers have probably encountered the dilemma of cutting operations being abruptly interrupted by tiny scrap warps (a fraction of a millimeter of metal scrap can have serious consequences). Today’s intelligent systems are able to anticipate risk areas and completely eliminate production accidents caused by uncontrolled scrap.

Intelligent toolpaths and collision avoidance systems

Collision avoidance is one of the key elements of the nesting process. The most destructive are the scraps that should fall smoothly through the grill, but then buckle or splash out of control – the moment the scrap is completely separated from the base material is the moment of high risk: if it wobbles, tilts, or falls upwards instead of vertically, it can not only damage the laser head, but also shatter the glass shield of the machine.

It is true that conventional laser cutting is the fastest in theory if it is done only sequentially on the inside contour (assuming the scrap comes off naturally). But the reality is that as soon as the scrap jams, buckles or is thrown upwards, the system becomes unstable – and a head-on collision is imminent (see above). Modern intelligent software automatically activates collision avoidance algorithms to perform a double safeguard: analyzing the structural integrity of the entire board, and then generating process-specific strategies to ensure cutting stability.

Intelligent Anti-Jam Cutting Strategy Explained

Assuming a part contains multiple irregular polygonal internal contours (both sharp and rounded edges), the software pre-scans these internal features to accurately identify areas of risk that could lead to jamming of the scrap, preventing it from falling smoothly through the grill.

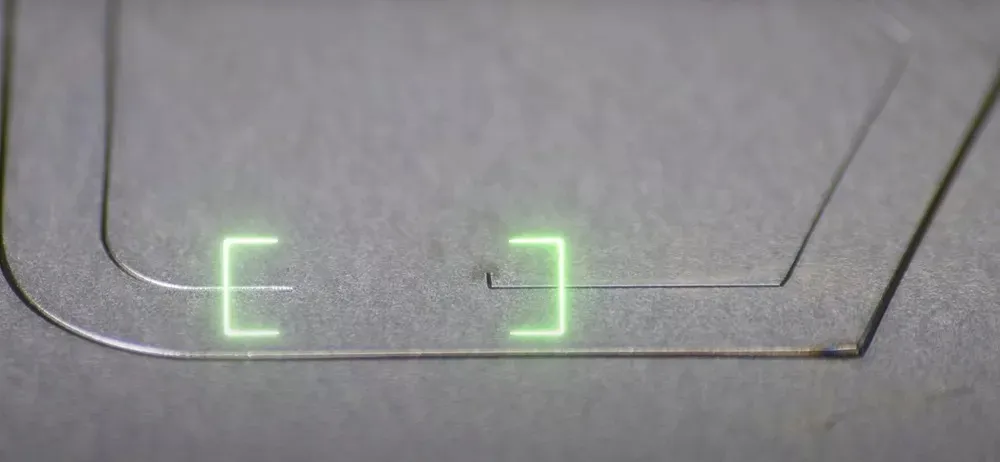

Once the risk has been identified, the system initiates adaptive adjustments. In the pre-cutting phase, the laser head makes more than 90% of the cut along the inner contour, leaving critical uncut areas to hold the scrap in place (see image below). This “hanging cut” allows the head to move quickly between contours without lifting the knife and always follows a safe path with “zero crossing of the cut area”.

Here, the laser head completes the inner contour cut, but leaves a small uncut section to hold the scrap in place. Later in the program, the head returns to cut this final section, allowing the scrap to fall vertically – no buckling or uncontrolled splashing!

When the final cut is made, especially at the end of the cycle, the laser head returns to the inner contours to make the final cut. At this point, the scrap falls vertically by gravity, while the cutting head still adheres to the logic of “avoiding the cut holes” to locate the next perforation point through the optimal safety path.

Here the programmers can customize the operation. For example, they can specify the order in which these last uncut segments are to be cut, as well as the exact location of these uncut segments on the inner contour. When customizing, the software identifies uncut segments that need to be lengthened – just to add strength and ensure that the scrap remains stable. This allows the cutting head to return for the final cut, after which the scrap will fall safely through the grid gap.

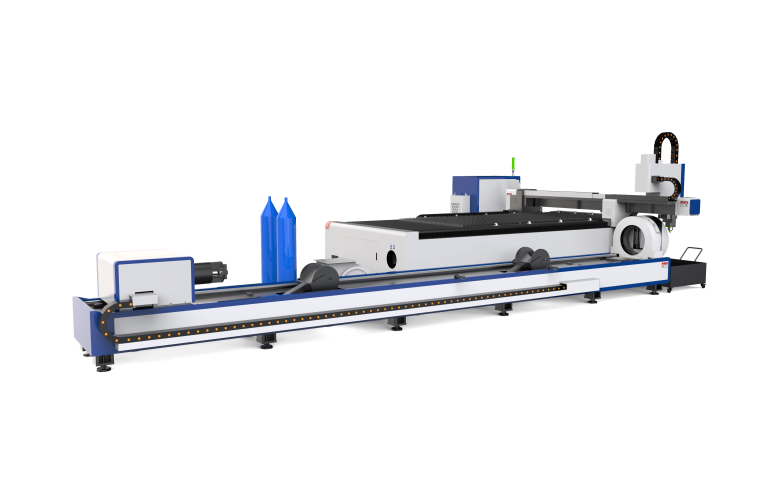

Laser is not a constraint

In some cases, a scrap crushing solution can be used. Here the laser head moves in a serrated or spiral motion, shredding the scrap into small pieces and ensuring that it falls reliably through the grate gap. This method is particularly suitable for tiny scraps in thin, lightweight materials – scraps that are prone to splashing out of control after cutting.

As laser cutting speeds have increased, this type of method has become increasingly popular. Years ago, programmers would prioritize optimizing the laser cutting path for maximum efficiency. It didn’t seem practical to add extra cycle time just to shred the scrap (or skeleton part). However, today’s laser cutting speeds are so fast that the added cycle time is often no longer a problem.

A similar idea is followed when “minimum heat” cutting is used. In this case, the software divides the sheet into zones and instructs the cutting head to alternate between the zones. This head movement does increase the total cutting time. However, cutting in a way that minimizes the spread of heat helps to avoid part distortion caused by heat buildup in small areas of the sheet – distortion that could cause the final cut part to fail to meet specified tolerances.

The same logic applies to collision avoidance of part scrap. The cutting cycle may be extended – partially cutting all internal features first and then finally cutting the remaining uncut portion – but in most cases the increased cycle time is not significant. To reiterate, the laser itself is not the limiting factor unless scrap buckling causes a head bumping accident.

The Road to Laser Cutting Stability

These strategies come down to using smart toolpaths to ensure that parts remain stable and that small scrap falls cleanly and in a predictable manner. Think of it as a maintenance cost; perhaps customers complain that the laser isn’t taking the fastest path, but when the laser head rolls over and crashes, the problem is serious.

Collision avoidance in laser cutting may not be cool enough, but it is absolutely critical. Once a cutting head is damaged, production comes to a complete standstill while waiting for the laser machine to come back online. If these types of accidents are frequent, the cost to the business will far outweigh any other issues. Truly great operations make full use of software and cutting strategies to maximize the benefits of the shop’s most valuable capital investment.