Five laser welding defects in the solution — Industrial Applications

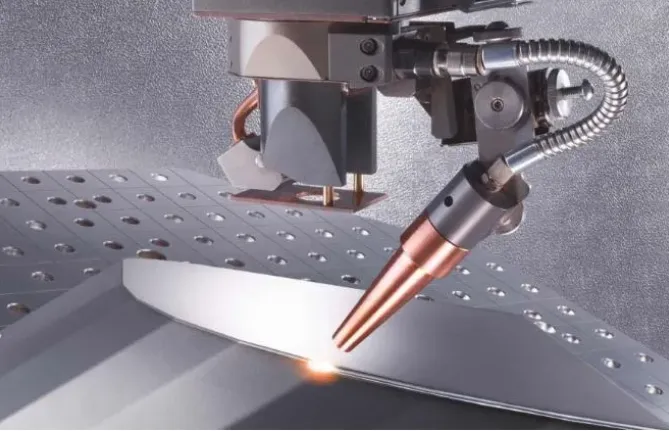

With the development of industrial manufacturing in the direction of high-end, intelligent, green, new energy vehicles, lithium batteries, semiconductors and emerging markets demand-driven, the demand for laser welding has been continuously stimulated, and the scope of application and market continues to expand. Especially in the field of consumer electronics, new energy vehicles and other fields, the requirements for laser welding is becoming more and more high, providing a huge market space for laser welding.

However, any processing method without a good grasp of its principles and processes will produce certain defects or defective products, laser welding is no exception. Only a good understanding of these defects, and learn how to avoid producing these defects, in order to better utilize the value of laser welding, processing the appearance of fine, high quality products. Chuangxin welding application engineers through long-term experience, summed up some common welding defects in the solution for industry colleagues to refer to the exchange!

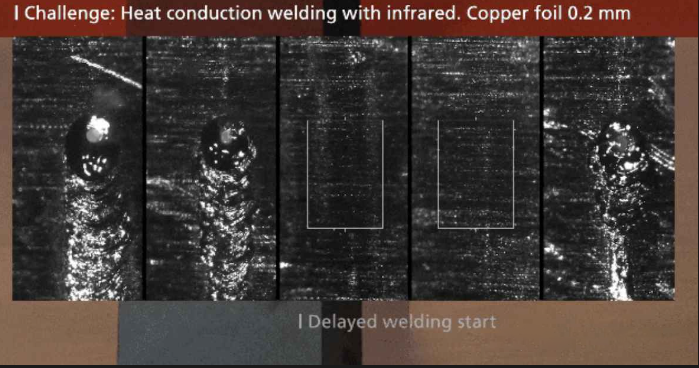

1.Cracks

Cracks produced in continuous laser welding is mainly thermal cracks, such as crystallization cracks, liquefaction cracks, etc., the reason is mainly due to the weld in the fully solidified before the production of large contraction force caused by filling wire, preheating and other measures can reduce or eliminate cracks.

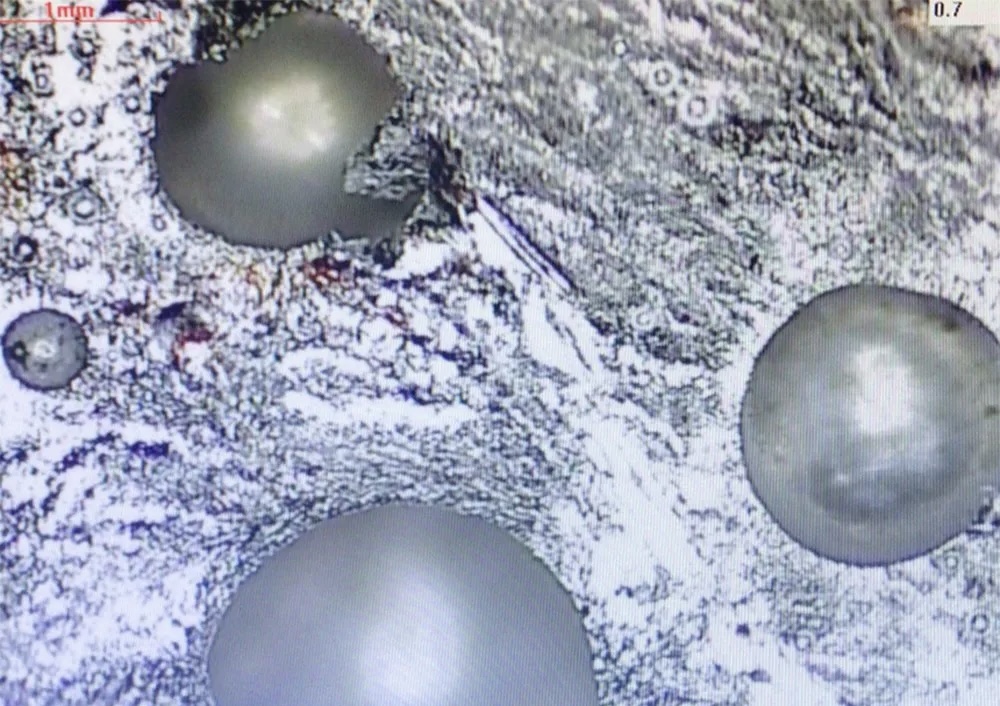

2. Porosity

Porosity is a defect that is more likely to occur in laser welding. The molten pool of laser welding is deep and narrow, and the cooling rate is very fast, so the gas generated in the liquid molten pool does not have enough time to escape, which can easily lead to the formation of porosity. However, the laser welding cooling fast, resulting in porosity is generally smaller than the traditional welding. Cleaning the surface of the workpiece before welding can reduce the tendency of porosity, and the direction of blowing will also affect the generation of porosity.

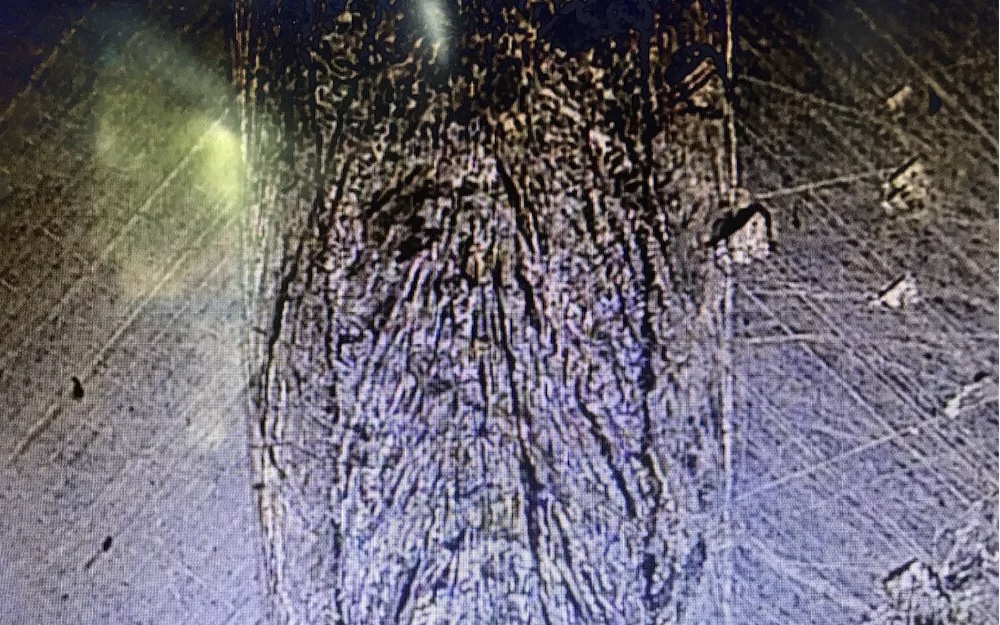

3.Splattering

The spatter generated by laser welding seriously affects the surface quality of the weld and can contaminate and damage the lens. Spatter and power density has a direct relationship, appropriate reduction of welding energy can reduce spatter. If the depth of fusion is insufficient, reduce the welding speed.

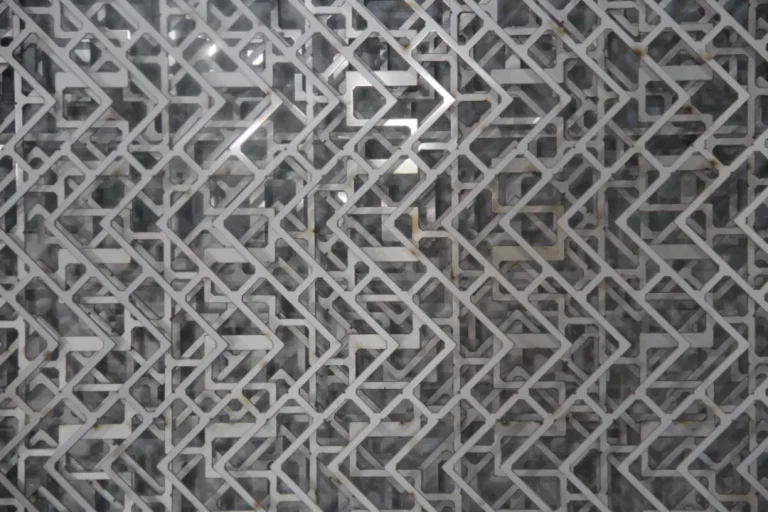

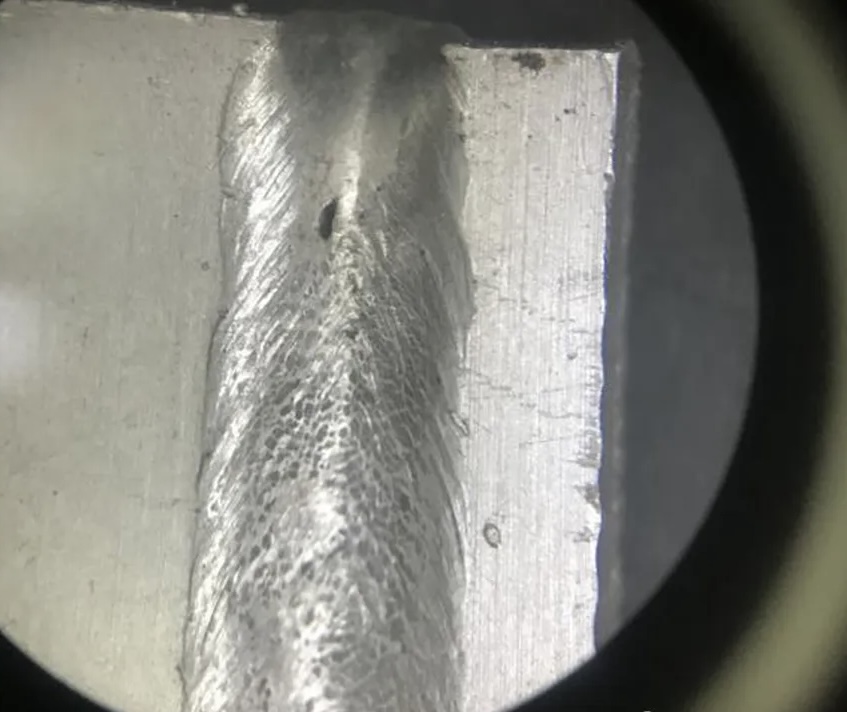

4.Bite Edge

If the welding speed is too fast, the liquid metal pointing to the center of the weld at the back of the hole will not be able to redistribute in time, and solidify on both sides of the weld to form a biting edge. Joint assembly gap is too large, filler melted metal is reduced, also prone to bite edge. Laser welding end, if the energy drop time is too fast, the hole is easy to collapse, resulting in localized biting, control power and speed matching can be a good solution to the generation of biting.

5.sinking of the center of the weld

If the welding speed is slow, the molten pool is large and wide, the amount of molten metal increases, and the surface tension is difficult to maintain the heavier liquid metal, the center of the weld seam will sink, forming a collapse and crater, at this time, it is necessary to appropriately reduce the energy density to avoid the molten pool collapse.

With a proper understanding of the defects that occur during the laser welding process and the reasons that lead to different defects, you can be more focused on solving the problem of weld anomalies during the laser welding process.