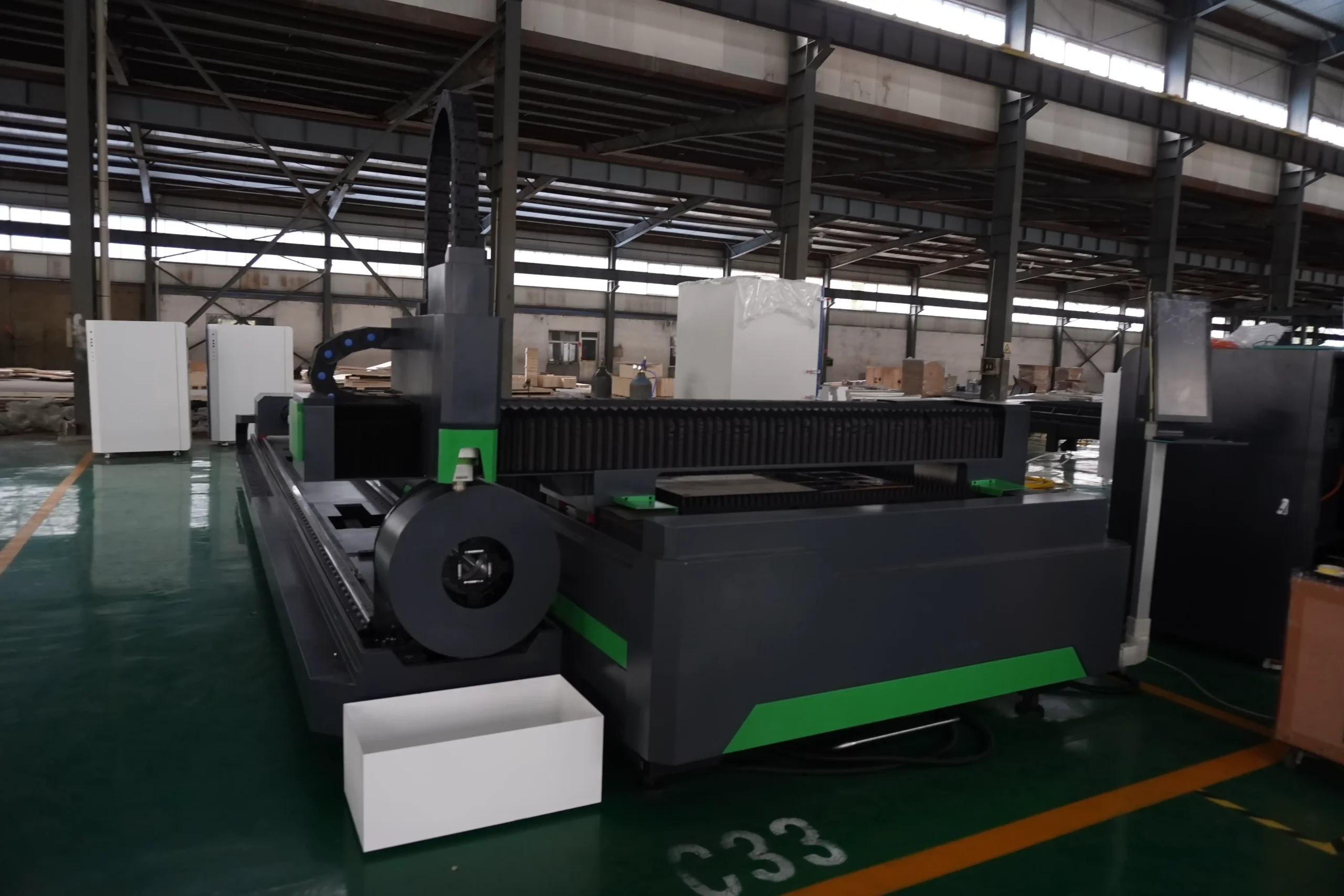

Laser cutting machine is a kind of high-tech equipment that utilizes laser beam for cutting and engraving, which is widely used in metal processing, advertisement production, decoration and decoration. Knowing how to operate the laser cutting machine correctly can not only improve the working efficiency, but also ensure the operation safety. The following is the operation guide of laser cutting machine, hope it can help you.

Preparation before operation

1.Check the status of the equipment: before using the laser cutting machine, you need to check the status of the equipment first to make sure that the parts are intact. Check whether the laser, reflector, focusing mirror, etc. are clean and have no damage or stains.

2.Confirm the working environment: the laser cutting machine should be placed in a dry, well-ventilated environment, avoiding direct sunlight and other heat sources. Make sure the operation area is clean and free of flammable and explosive materials.

3.Prepare cutting materials: Select the appropriate laser cutting parameters according to the materials to be cut. Different materials (e.g. metal, wood, plastic, etc.) have different requirements for laser power, speed, etc., which need to be adjusted according to specific conditions.

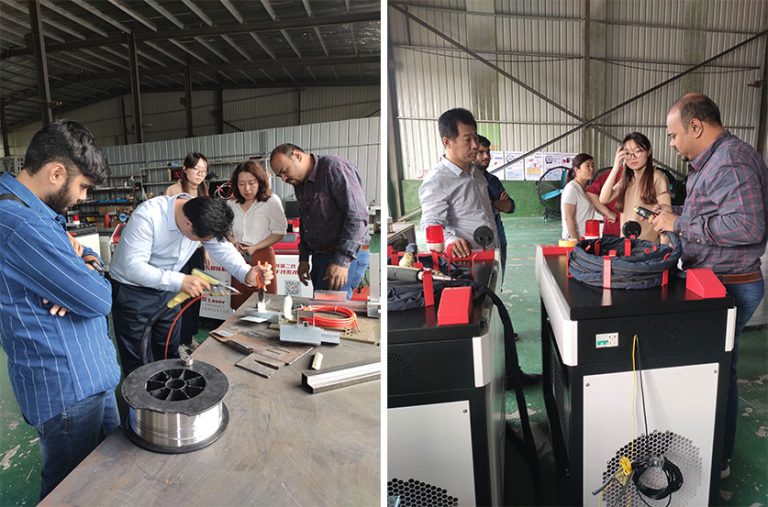

4.Wear protective equipment: the operator should wear suitable protective equipment, such as laser protective glasses, to prevent laser damage to the eyes. At the same time, it is recommended to wear protective gloves and overalls.

Operation steps of the laser cutting machine

1.Starting up the equipment: turn on the power and turn on the power switch of the laser cutting machine. Wait for the equipment self-test to complete, start the laser and cooling system to ensure the normal working temperature of the laser.

2.Set cutting parameters: according to the cutting material and requirements, set the laser power, cutting speed, gas pressure and other parameters. These parameters can usually be set through the control panel of the laser cutting machine or computer software.

3.Load cutting drawings: Import the drawing files to be cut into the control system of the laser cutting machine. Common file formats are DXF, DWG, PLT, etc. Make sure the size and position of the drawing are correct to avoid deviation when cutting.

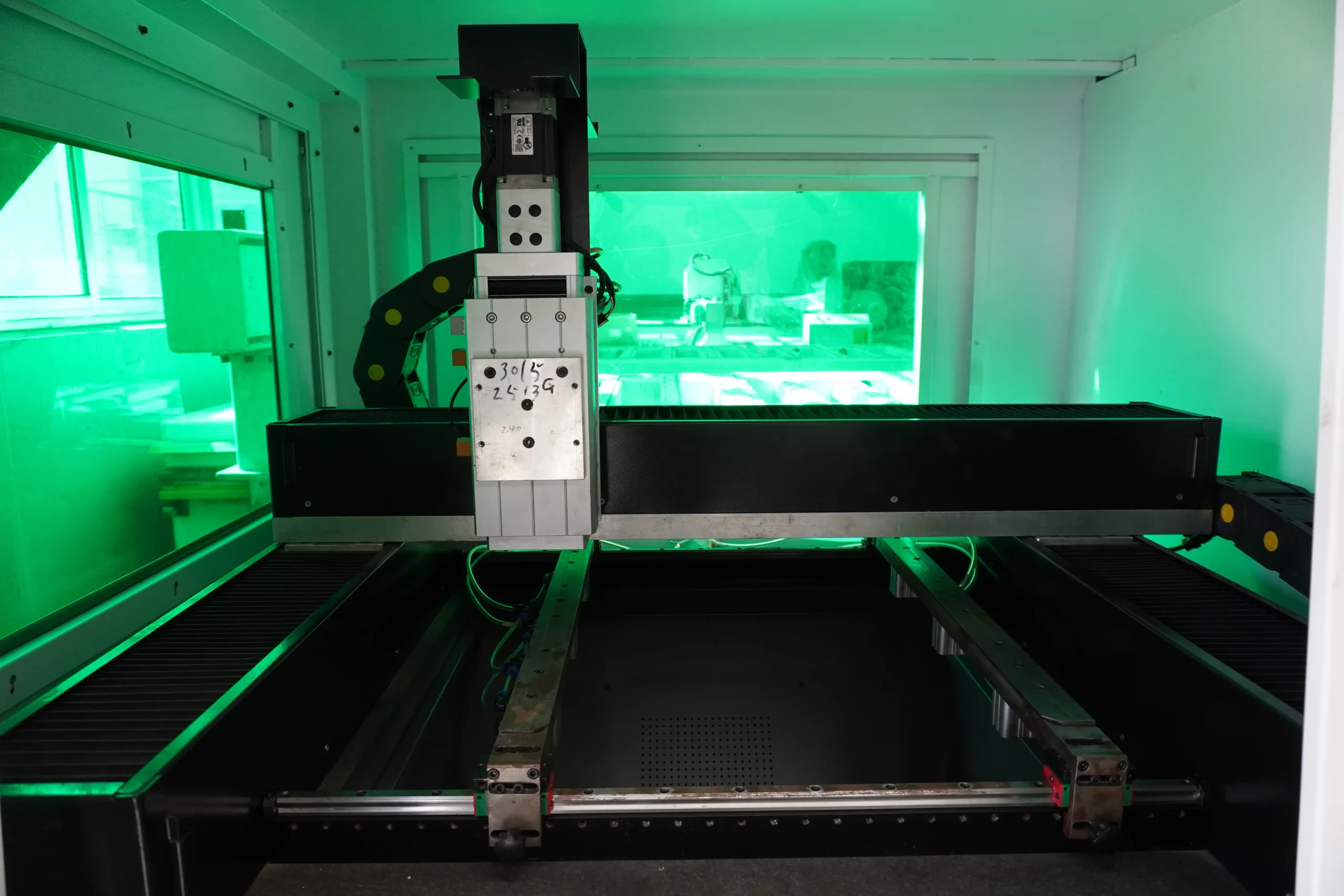

4.Fixing the cutting material: Place the material to be cut on the working table and use fixing clips or magnets to fix the material to ensure that the material will not move or vibrate during the cutting process.

5.Focus and Alignment: Adjust the height and focal length of the laser head to focus the laser beam on the material surface. Use an alignment tool or software for precise alignment to ensure that the cutting path is consistent with the drawing.

6.Start cutting program: After confirming that the cutting parameters and material are fixed correctly, start the cutting program. The laser cutter will cut according to the preset path. During the operation, keep observing to ensure that the cutting is carried out normally. If any abnormality is found, stop the operation immediately and troubleshoot the problem.

Post-Operation Disposal

1.Shutting Down the Equipment: When cutting is complete, turn off the laser and cooling system and disconnect the power supply. Wait for the equipment to cool down completely and then clean up the worktable and cutting waste.

2.Check the cutting effect: Remove the cut material and check the cutting effect. Ensure that the cut is smooth and without obvious burrs or slag. If problems are found, adjust the cutting parameters and cut again.

3.Maintenance and care: Regularly maintain and care for the laser cutting machine. Clean the optical lens, check the laser and cooling system to ensure the normal operation and service life of the equipment.

Safety Precautions

1.PROTECTION: Protective eyewear must be worn when operating the laser cutting machine to prevent eye injury from laser radiation. Avoid direct laser light on the skin to prevent burns.

2.Ventilation and smoke exhaust: the laser cutting process will produce smoke and harmful gases, the operating environment should be equipped with good ventilation and smoke exhaust equipment to ensure air quality.

3.Operation standardization: operate in strict accordance with the operation regulations, avoid manual adjustment or overhaul when the equipment is running. Ensure that there are no unrelated personnel around the equipment to avoid accidental injury.

4.Emergency Handling: Familiarize yourself with the emergency handling measures of the equipment, such as the location of the emergency stop button and fire extinguisher in the event of equipment failure or fire, to ensure that you can respond quickly in case of emergency.

Correct operation of the laser cutting machine not only improves the cutting efficiency and quality, but also ensures the operation safety. Through reasonable preparation, standardized operation and regular maintenance, the laser cutting machine will become a powerful assistant in your work. We hope that the above guide can help you better master the operation skills of laser cutting machine and realize more efficient and safer work.