Laser cutting has been a cornerstone of modern manufacturing since its first application in the 1970s, widely used for high-precision processing of sheet metal, plastics, ceramics, wood, glass, and more. Its advantages—non-contact operation, high efficiency, narrow kerf, and minimal heat-affected zone—make it indispensable in industrial production. This article systematically explains the working principle of laser cutting, covering five mainstream processes: flame cutting, fusion cutting, compressed air cutting, plasma-assisted cutting, and vaporization cutting. We also dive into the key parameters affecting cut quality—laser power, focus position, cutting speed, gas purity, and nozzle diameter—and show how to optimize them using technical parameter tables. Plus, we provide standards for evaluating edge quality to help operators improve precision and productivity.

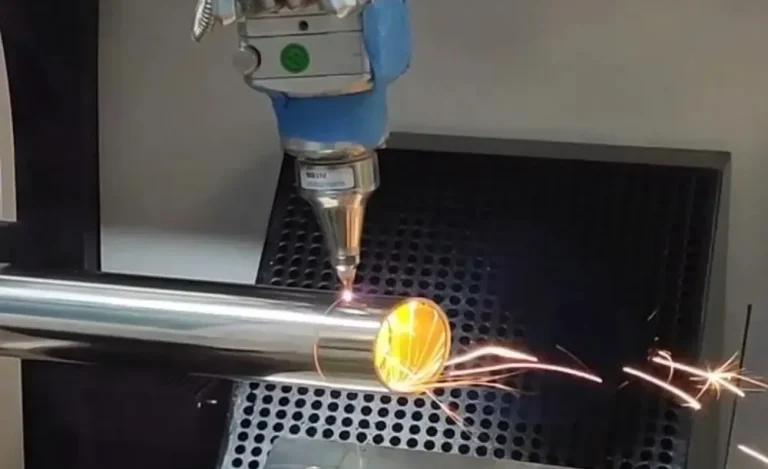

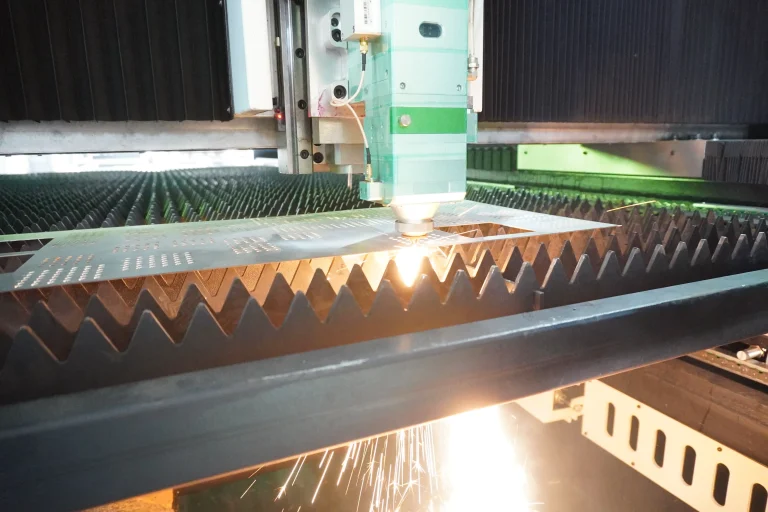

Laser cutting

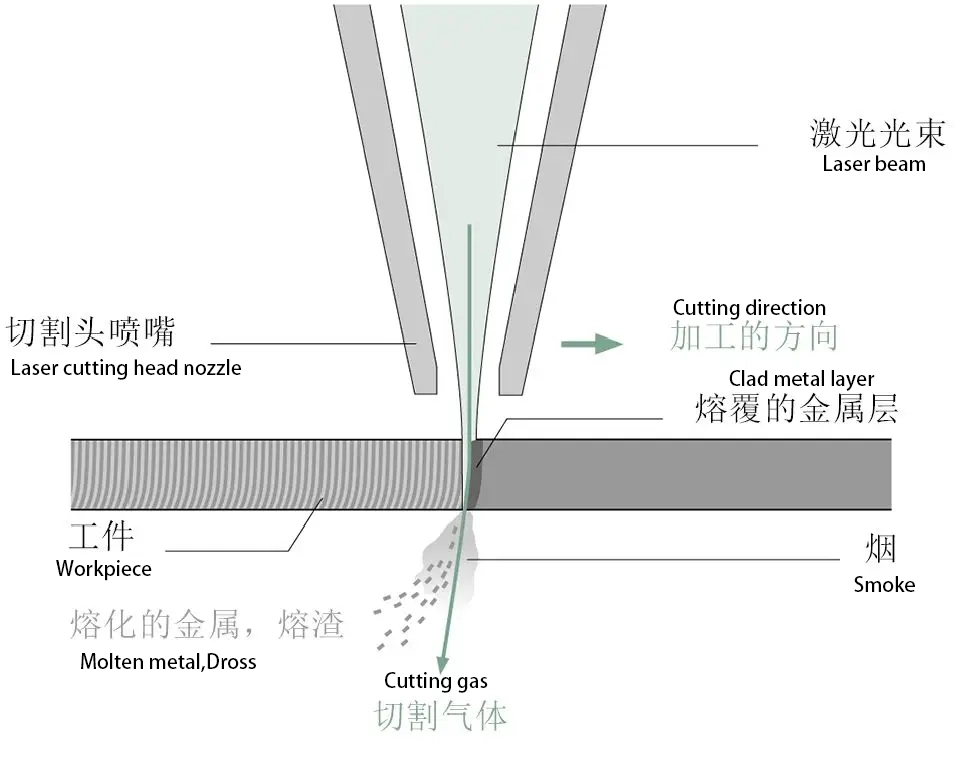

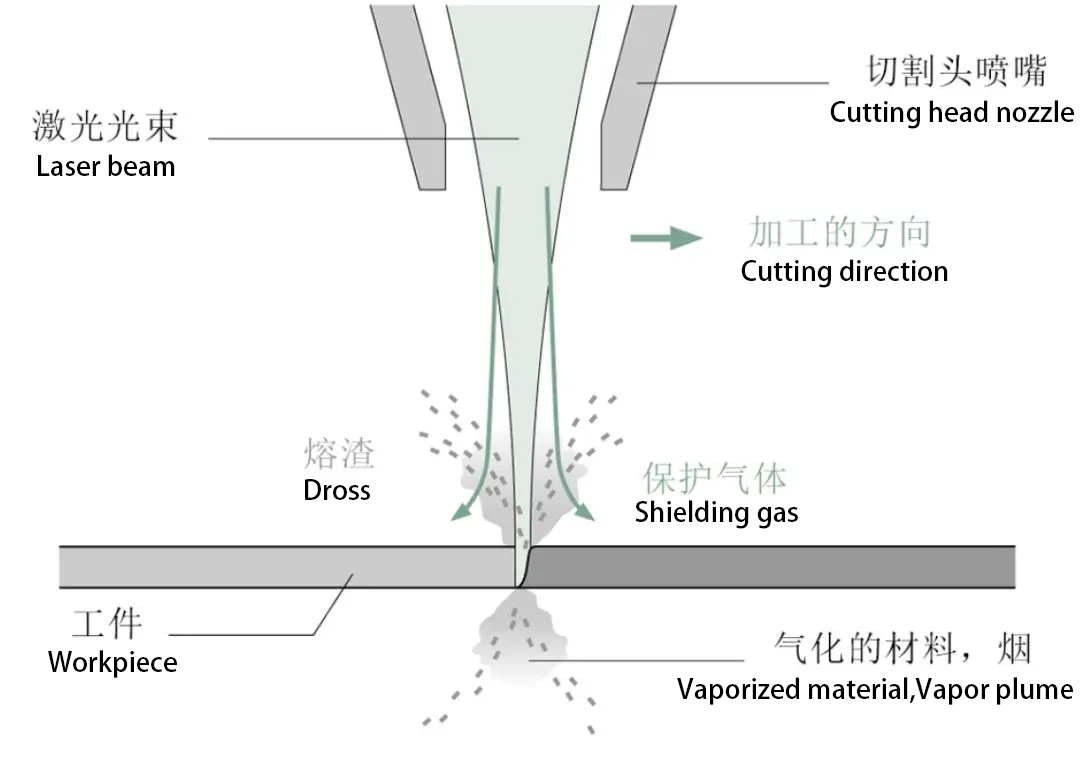

When the focused laser beam strikes the workpiece, the irradiated area rapidly heats up to melt or vaporize the material. Once the laser beam penetrates the workpiece, the cutting process begins: the laser beam moves along the contour line while melting the material. Typically, a jet of gas is used to blow away the molten material from the cut, leaving a narrow slit between the cut section and the plate frame. This slit is nearly as wide as the focused laser beam itself.

Flame Cutting

Flame cutting is a standard process for cutting low-carbon steel, utilizing oxygen as the cutting gas. Oxygen is pressurized up to 6 bar and blown into the cut. There, the heated metal reacts with the oxygen: combustion and oxidation commence. This chemical reaction releases substantial energy (up to five times that of laser energy) to assist the laser beam in cutting.

Fusion Cutting

Fusion cutting is another standard process used for cutting metals. It can also be applied to other fusible materials, such as ceramics.

Nitrogen or argon is used as the assist gas, which blows through the kerf at pressures ranging from 2 to 20 bar. Both argon and nitrogen are inert gases, meaning they do not react with the molten metal in the cut. Instead, they simply expel the molten material downward. At the same time, the inert gas protects the cut edge from oxidation by shielding it from atmospheric air.

Compressed Air Cutting

Compressed air can also be used for cutting thin sheets. Air pressure of 5–6 bar is sufficient to blow away the molten metal from the kerf. Since air consists of approximately 80% nitrogen, compressed air cutting is essentially a form of fusion cutting.

Plasma-Assisted Cutting

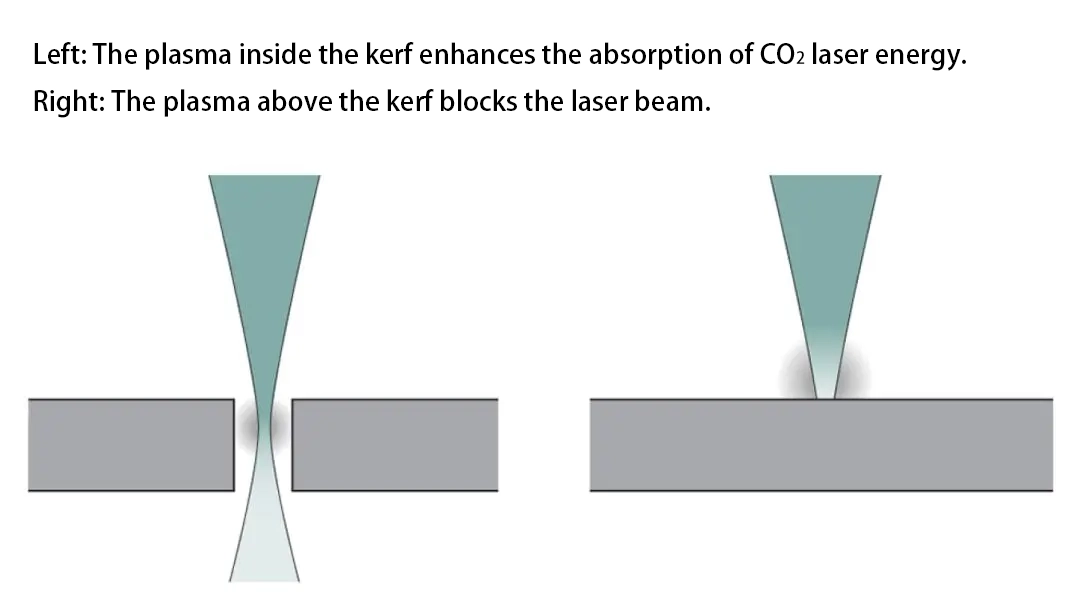

When process parameters are properly set, a plasma plume forms within the kerf during plasma-assisted fusion cutting. This plasma plume consists of ionized metal vapor and ionized assist gas. The plasma absorbs energy from the CO₂ laser and transfers it into the workpiece, increasing the amount of energy coupled into the material. As a result, the material melts more rapidly, enabling higher cutting speeds. Therefore, this process is also known as high-speed plasma cutting.

In fact, the plasma plume is transparent to solid-state lasers (e.g., fiber lasers), meaning it does not absorb their energy effectively. Hence, plasma-assisted fusion cutting only works effectively with CO₂ lasers.

Vaporization Cutting

Vaporization cutting involves the evaporation of material, minimizing thermal effects on surrounding areas. This process can be achieved using a continuous CO₂ laser to evaporate materials with low heat absorption and high vaporization characteristics, such as thin plastic films, wood, paper, foam, and other non-melting materials.

Ultra-Short Pulse Lasers

Ultra-short pulse lasers enable this technology to be applied to a wider range of materials. Free electrons in metals absorb the laser energy and rapidly heat up. The laser pulses do not interact with molten particles or plasma; instead, the material directly sublimates without sufficient time for heat diffusion into the surrounding material. During picosecond pulse ablation, there are minimal thermal effects, resulting in no melting or burr formation.

The laser beam vaporizes and burns the material. The pressure of the vapor ejects the molten debris and dross from the kerf.

Parameters: Adjusting the Machining Process

Many parameters influence the laser cutting process—some depend on the technical capabilities of the laser and machine tool, while others can be adjusted.

Polarization

Polarization indicates the percentage of laser light that is polarized. A typical polarization level is around 90%. This degree of polarization is generally sufficient for high-quality cutting.

Focal Spot Diameter

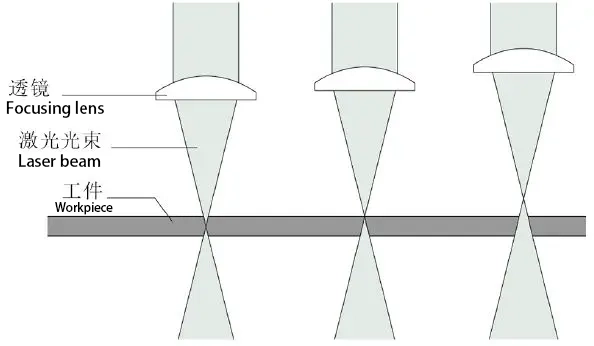

The focal spot diameter affects the kerf width. It can be changed by using focusing lenses with different focal lengths. A smaller focal spot diameter results in a narrower kerf.

Focus Position

The focus position determines the beam diameter, power density on the workpiece surface, and the shape of the cut profile. Proper positioning—above, at, or below the surface—is critical for achieving optimal cut quality, especially in thick-section materials.

Laser Power

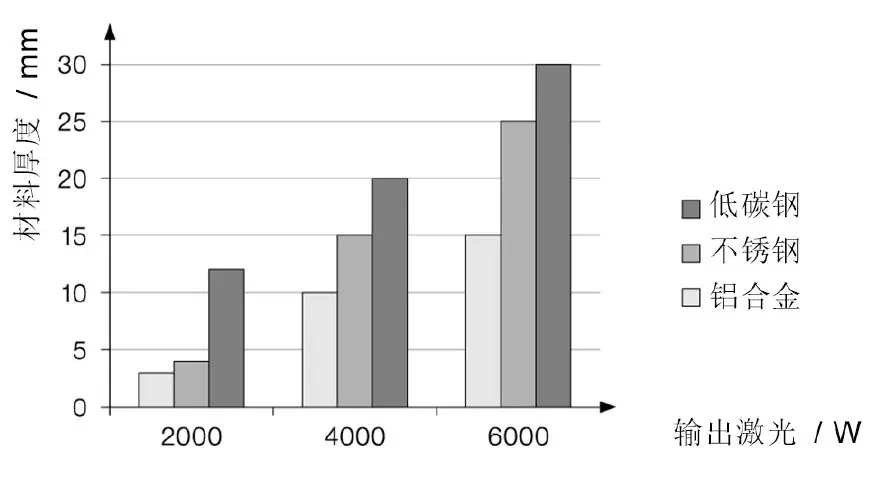

The laser power should be matched to the processing type, material type, and thickness. The power must be sufficiently high so that the power density on the workpiece exceeds the processing threshold.

Operating Modes

Continuous mode is primarily used for cutting standard contours in metals and plastics ranging from millimeters to centimeters in size. For melting through holes or producing precise contours, low-frequency pulsed lasers are employed.

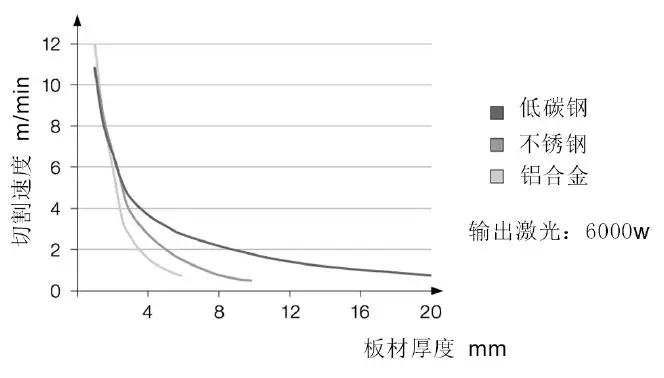

Cutting Speed

Laser power and cutting speed must be matched. Cutting speeds that are too fast or too slow will result in increased surface roughness and burr formation.

Nozzle Diameter

The diameter of the nozzle determines the gas flow rate and the shape of the airflow exiting the nozzle. The thicker the material, the larger the diameter of the gas jet needs to be, accordingly, the diameter of the nozzle outlet must also increase.

Gas Purity and Pressure

Oxygen and nitrogen are frequently used as cutting gases. The purity and pressure of the gas affect the quality of the cut.

When using an oxy-fuel flame for cutting, the gas purity must reach 99.95%. For thicker steel plates, lower gas pressures are used.

When utilizing nitrogen for melt cutting, the gas purity needs to reach 99.995% (ideally 99.999%), and higher gas pressures are required for cutting thick steel plates.

Technical Parameter Table

In the early days of laser cutting, users had to determine the processing parameters through trial runs themselves. Now, established processing parameters are stored in the control unit of the cutting system. There is corresponding data for each type and thickness of material. The technical parameter table allows even those unfamiliar with this technology to operate a laser cutting machine smoothly.

This translation covers all the key points mentioned in your original text about nozzle diameters, gas purity and pressure requirements, and the evolution of technical parameter tables in laser cutting operations.

Laser cutting technology, with its high efficiency, precision, and flexibility, has become the preferred solution in modern industrial manufacturing. Whether it’s flame cutting leveraging chemical energy for faster mild steel processing, vaporization cutting enabling thermal-damage-free fine machining, or intelligent operation via parameter tables—each highlights the technology’s versatility. Understanding the fundamentals of laser cutting—its principles, process types, and key parameter settings—not only improves cut quality but also extends equipment life and reduces operating costs. As automation and smart control advance, the applications of laser cutting will expand even further, playing a critical role in new energy, aerospace, and automotive manufacturing. Continuous learning and process optimization are essential skills for every metalworking professional.