In today’s industrial manufacturing landscape, laser marking machines have become the go-to solution for permanent, high-precision identification across a wide range of materials. According to industry reports, laser marking now holds over 90% of the market share in the marking and printing sector. As a leading china laser marking machine manufacturer, we explore why this technology is so widely adopted and what benefits it brings—especially when used for sample marking and mass production.

1.Permanent & Durable Markings

One of the most significant advantages of laser marking is the permanence of the results. Unlike inkjet or embossed markings that can fade or wear off over time, laser marks are resistant to:

Environmental factors (temperature extremes, humidity)

Chemical exposure (acids, solvents)

Physical abrasion

This makes laser marking ideal for industries requiring long-term traceability, such as automotive, aerospace, medical devices, and electronics.

2.Enhanced Anti-Counterfeiting Protection

Laser marking offers a high level of security and anti-counterfeiting capabilities. The precision and complexity of laser-engraved patterns or data make them extremely difficult to replicate or alter without detection. This is especially valuable in sectors like luxury goods, pharmaceuticals, and branded products where product authenticity is critical.

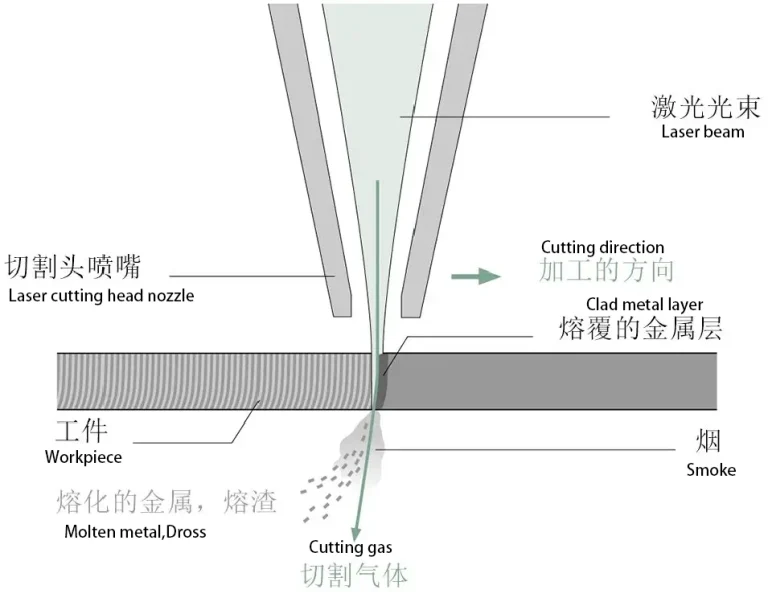

3.Non-Contact Processing – No Damage to Materials

Laser marking is a non-contact process, meaning no mechanical force is applied during engraving. This eliminates the risk of material deformation, internal stress, or surface damage. It also ensures:

No tool wear

No toxic emissions or pollution

Compatibility with sensitive components and surfaces

This makes it suitable for both flat and irregularly shaped workpieces.

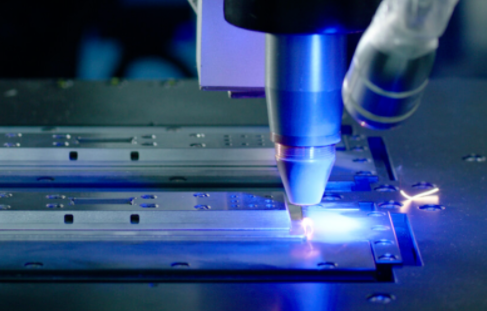

4.Wide Material Compatibility

Modern laser marking machines are highly versatile and capable of processing a broad range of metallic and non-metallic materials, including:

Metals: Aluminum, copper, stainless steel, titanium

Non-metals: Plastics, wood, glass, ceramics, leather

This flexibility allows manufacturers to use a single machine for multiple applications, reducing equipment costs and increasing productivity.

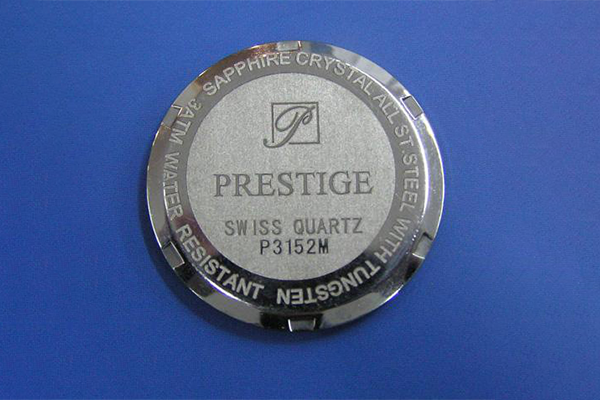

5.High Precision & Fine Detailing

With a minimum line width of just 0.04mm, laser marking machines deliver ultra-fine, high-resolution engravings. Whether you’re marking small electronic components or creating intricate designs on jewelry, laser marking ensures clarity, consistency, and aesthetic appeal.

It’s particularly effective for:

Printing 2D barcodes and QR codes

Engraving serial numbers and batch codes

Customizing promotional items or gifts

Compared to traditional methods like stamping or inkjet printing, laser marking provides superior sharpness and longevity.

6.Low Operating Costs

Laser marking systems are known for their low energy consumption and minimal maintenance requirements. Unlike consumable-dependent methods (like inkjet printers), laser machines do not require frequent replacement of inks or tools. Once set up, they offer:

High-speed operation

Long service life

Reduced downtime

This makes them a cost-effective solution for both small businesses and large-scale manufacturers.

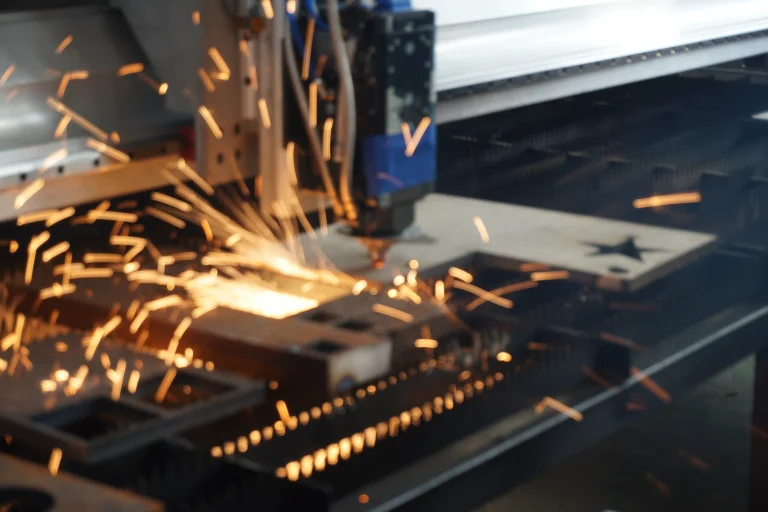

7.High Processing Efficiency

Time is money in manufacturing—and laser marking delivers speed without compromising quality. A typical marking process can be completed in just a few seconds, depending on the design complexity and power of the machine. This efficiency supports:

Faster production cycles

Real-time customization

Integration into automated production lines

8.Environmentally Friendly & Sustainable

As industries shift toward greener practices, laser marking stands out as an eco-friendly alternative to chemical etching and ink-based printing. It produces no harmful waste, requires no solvents, and operates with minimal energy usage—making it a sustainable choice for environmentally conscious companies.

Laser Marking vs Traditional Methods

Compared to traditional techniques such as mechanical engraving, chemical etching, screen printing, and inkjet printing, laser marking offers:

Lower overall costs

Higher flexibility and customization

Computer-controlled precision

Consistent, durable results

Whether you’re using a fiber laser marking machine for metals or a CO2 laser marking machine for non-metallic materials, the technology represents a major leap forward in modern manufacturing and product identification.

The dominance of laser marking machines in today’s market is no coincidence—it’s the result of technological innovation, cost-effectiveness, and unmatched performance. As a professional laser marking machine manufacturer in china, we believe that adopting this advanced technology is not only a smart business decision but also a step toward future-proofing your production capabilities.

If you’re looking to upgrade your marking processes, choosing the right laser marking system will ensure you stay competitive, compliant, and ahead of the curve in an ever-evolving global market.