1、Laser Welding

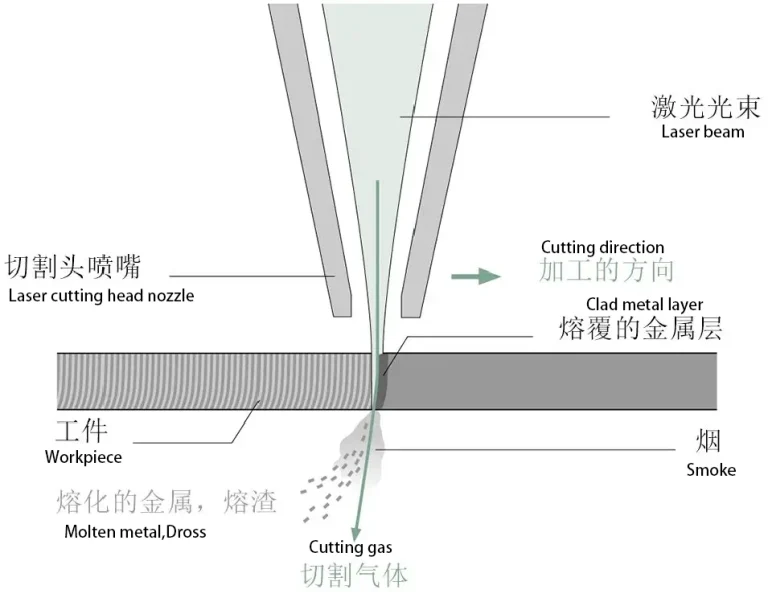

Laser Welding: Laser radiation heats the surface to be processed, the surface heat spreads internally through heat conduction, and the workpiece is melted to form a specific molten pool by controlling the laser parameters such as the width, energy, peak power and repetition frequency of the laser pulse.

Laser welding can be realized using a continuous or pulsed laser beam, the principle of laser welding can be divided into heat conduction welding and laser deep fusion welding. Power density less than 10 ~ 10 W / cm for thermal conduction welding, this time shallow depth of fusion, welding speed is slow; power density greater than 10 ~ 10 W / cm, the metal surface by the thermal effect of concave into the “hole”, the formation of the deep melt welding, welding speed, depth and width ratio of large features.

Laser welding technology is widely used in automobiles, ships, airplanes, high-speed rail and other high-precision manufacturing areas, to bring a significant improvement in people’s quality of life, but also to lead the home appliance industry into the era of precision work.

Especially after Volkswagen’s creation of the 42-meter seamless welding technology, which greatly improved the integrity and stability of the body, the leading home appliance company, Haier Group, proudly launched the first washing machine produced using the laser seamless welding technology, the advanced laser technology can bring great changes to people’s lives!

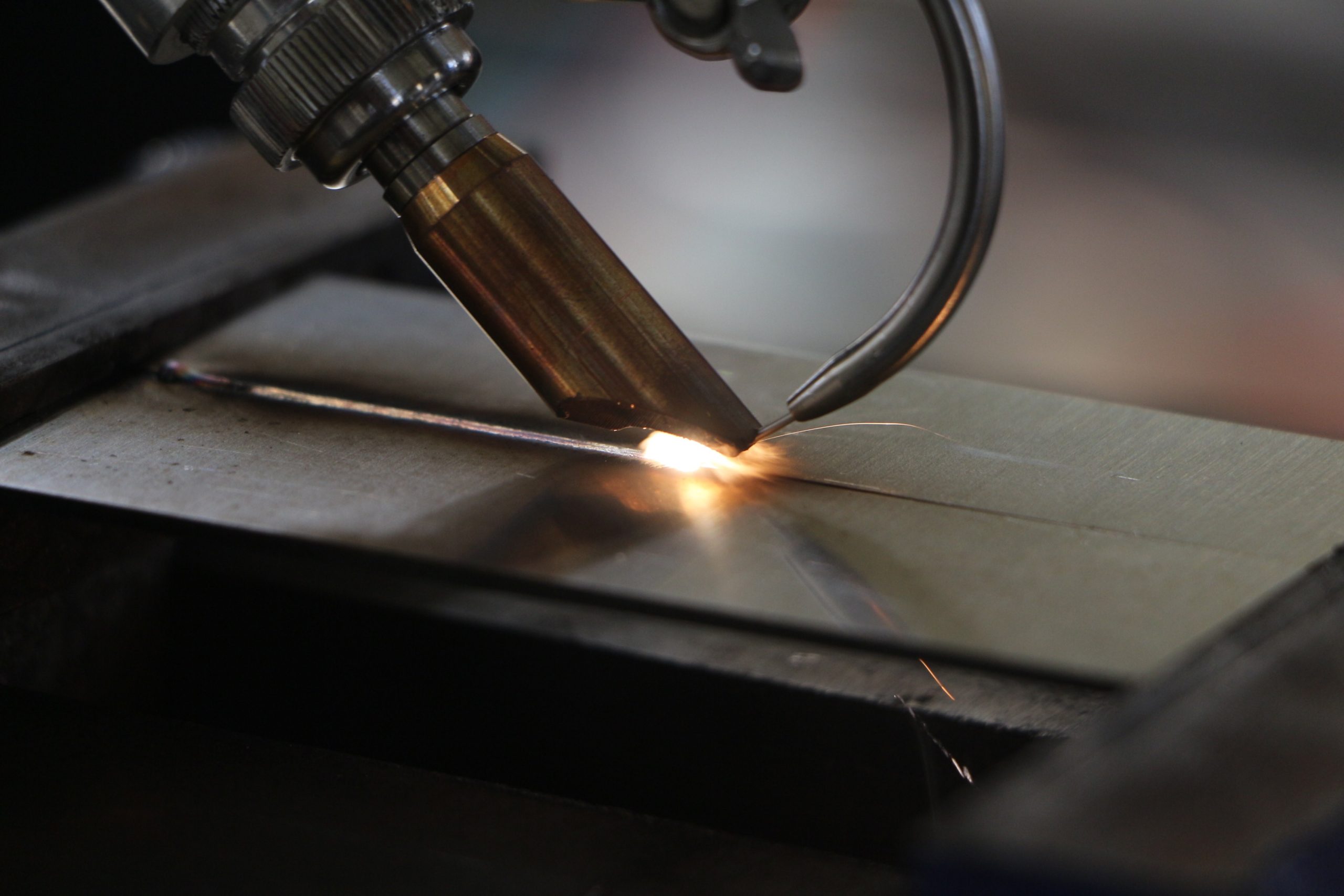

2、Laser composite welding

Laser composite welding is a combination of laser beam welding and MIG welding technology to obtain the best welding effect, fast and weld bridging ability, is currently the most advanced welding method.

The advantages of laser composite welding are: high speed, small thermal deformation, small heat-affected area, and to ensure the metal structure and mechanical properties of the weld.

Laser composite welding is suitable for many other applications in addition to the welding of thin sheet structural parts for automobiles. For example, the technology is used in the production of concrete pumps and mobile crane booms, which require the processing of high-strength steels, where conventional technology often leads to increased costs due to the need for other auxiliary processes (e.g. preheating).

Furthermore, the technology can also be used in the manufacture of rail vehicles and conventional steel structures (e.g. bridges, fuel tanks, etc.).

3、Friction stir welding

Stir friction welding is the use of friction heat and plastic deformation heat as a welding heat source. Stir friction welding welding process is by a cylinder or other shapes (such as with threaded cylinders) stirring needle into the joints of the workpiece, through the high-speed rotation of the welding head, so that it is friction with the welded workpiece material, so that the connection parts of the material temperature rise and soften.

Stir friction welding in the welding process workpiece to be rigidly fixed on the back pad, the welding head side of the high-speed rotation, the side of the seam along the workpiece and the relative movement of the workpiece.

The protruding part of the weld head reaches into the material for friction and stirring, the shoulder of the weld head and the surface of the workpiece friction heat, and is used to prevent the plastic state of the material overflow, and at the same time can play a role in removing the surface of the oxide film.

At the end of a friction stir weld, a keyhole is left at the end of the weld. Usually this keyhole can be removed or sealed by other welding methods.

Friction stir welding can realize the welding between dissimilar materials, such as metal, ceramics, plastics and so on. Friction stir welding has high welding quality, not easy to produce defects, easy to realize mechanization, automation, stable quality, low cost and high efficiency.

4、Electron beam welding

Electron beam welding is the use of accelerated and focused electron beam bombardment placed in a vacuum or non-vacuum weldments generated by the thermal energy welding method.

Electron beam welding is widely used in aerospace, atomic energy, national defense and military industry, automotive and electrical and electronic instrumentation and many other industries because of the advantages of not using electrodes, not easy to oxidize, good process repeatability and small heat distortion.

How Electron Beam Welding Works:

Electrons escape from the emitter (cathode) in the electron gun, under the action of the accelerating voltage, the electrons are accelerated to 0.3 to 0.7 times the speed of light, with a certain kinetic energy. And then by the electron gun in the electrostatic lenses and electromagnetic lenses, convergence into a very high power density of the electron beam flow.

This electron beam flow impact on the surface of the workpiece, electronic kinetic energy into thermal energy and make the metal quickly melt and evaporate. Under the action of high-pressure metal vapor, the surface of the workpiece is quickly “drilled” a small hole, also known as “keyhole”, with the relative movement of the electron beam and the workpiece, the liquid metal along the small holes around the flow to the back of the molten pool, and cooled and solidified to form a weld.

Key features of electron beam welding:

Electron beam penetration ability, power density is very high, the weld depth and width ratio is large, can reach 50:1, can realize the large thickness of the material once formed, the maximum welding thickness of 300mm.

Welding accessibility is good, welding speed is fast, generally more than 1m/min, heat-affected zone is small, welding deformation is small, welding structure with high precision.

Electron beam energy can be adjusted, the thickness of the welded metal can be as thin as 0.05mm to as thick as 300mm, without beveling, a welded shape, which is unattainable by other welding methods.

Electron beam welding can be used for a wide range of materials, especially for active metals, refractory metals and high quality requirements of the workpiece welding.

5、Ultrasonic metal welding

Ultrasonic metal welding is the use of ultrasonic frequency mechanical vibration energy, connecting the same metal or dissimilar metal a special method.

Metals are ultrasonically welded without delivering electric current to the workpiece nor applying high temperature heat source to the workpiece, but only under static pressure, the frame vibration energy is transformed into friction work, deformation energy and limited temperature rise between the workpieces. Metallurgical bonding between the joints is a kind of solid state welding realized without melting of the base material.

It effectively overcomes the phenomena of spattering and oxidation produced during resistance welding. Ultrasonic metal welder can carry out single-point welding, multi-point welding and short-strip welding for copper, silver, aluminum, nickel and other non-ferrous wires or sheet materials. It can be widely used in the welding of silicon controlled leads, fuse pieces, electrical leads, lithium battery pole pieces and pole lugs.

Ultrasonic metal welding utilizes high-frequency vibration waves transmitted to the metal surface to be welded, under pressure, so that the two metal surfaces friction each other and the formation of fusion between molecular layers.

The advantages of ultrasonic metal welding lies in the fast, energy-saving, high fusion strength, good electrical conductivity, no sparks, close to the cold state of processing; disadvantages of the welded metal parts can not be too thick (generally less than or equal to 5mm), the weld can not be too large, the need to pressurize.

6、Flash butt welding

The principle of flash butt welding is the use of butt welding machine to make contact with the two ends of the metal, through the low voltage of the strong current, to be heated to a certain temperature of the metal is softened, axial pressure top forging, the formation of butt welding head.

Two weldments are not in contact before the two clamp electrode clamping and connecting the power supply, move the movable fixture, the two weldments end face gently contact that is electrically heated, the contact point due to heating the formation of liquid metal bursting, jet sparks form flash, continuous movement of the movable fixture, continuous flash, the weldment ends get heated to reach a certain temperature, squeeze the two workpieces end face, cut off the welding power supply, solidly welded together.

The use of resistance heating of the weldment joints to produce flash at the contact point, melting the weldment end face metal, quickly apply the top force to complete the welding.

Reinforcing bar flash butt welding is the two bars installed and put into butt form, the use of welding current through the two bars at the point of contact with the resistance of the heat generated by the point of contact, so that the point of contact with the metal melting, resulting in strong spattering, the formation of flash, accompanied by irritating odors, the release of trace molecules, and the rapid application of the top of the forging force to complete a method of pressure welding.