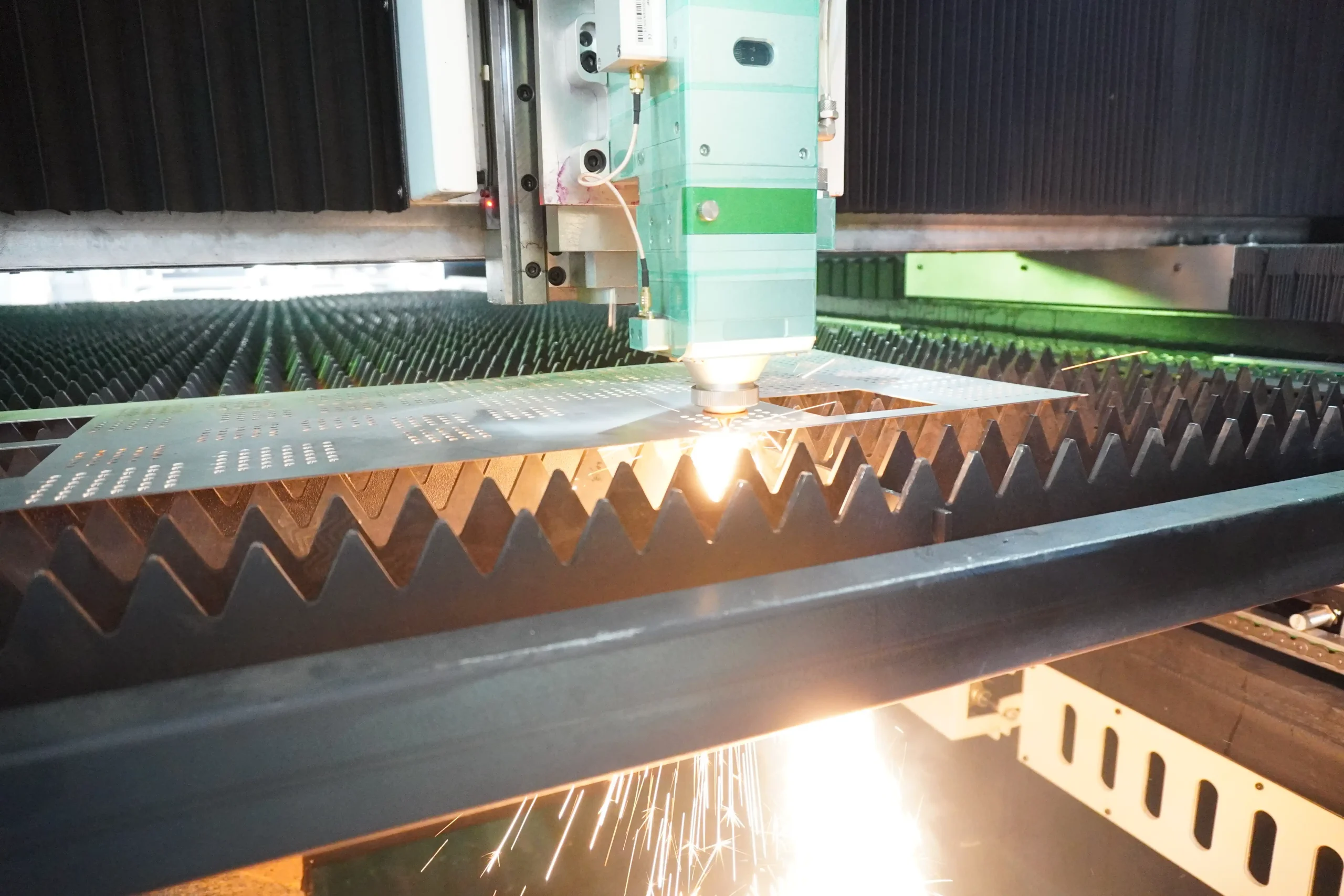

In the current processing industry, it is common to use laser cutting machines for processing. As laser cutting machines are characterized by high efficiency and flexibility, they can solve the inconvenience caused by traditional CNC punching machines. Laser cutting machine adopts non-contact processing program, with no mechanical stress and deformation, simple operation, high cutting accuracy, small heat-affected zone of the significant characteristics.

Laser cutting is the most important application technology in the laser processing industry, accounting for more than 70% of the entire laser processing industry. Laser cutting is currently the world’s advanced cutting technology. As it has the advantages of precision manufacturing, flexible cutting, shaped processing, one-time molding, high speed and high efficiency, it solves many problems in industrial production that cannot be solved by conventional methods. Laser can cut most metal materials and non-metal materials.

What is laser cutting?

Laser cutting is the use of a high energy density laser beam to heat a workpiece so that the temperature rises rapidly, reaching the boiling point of the material in a very short period of time, and the material begins to vaporize, forming steam. These vapors are ejected at high speed while forming a cut in the material.

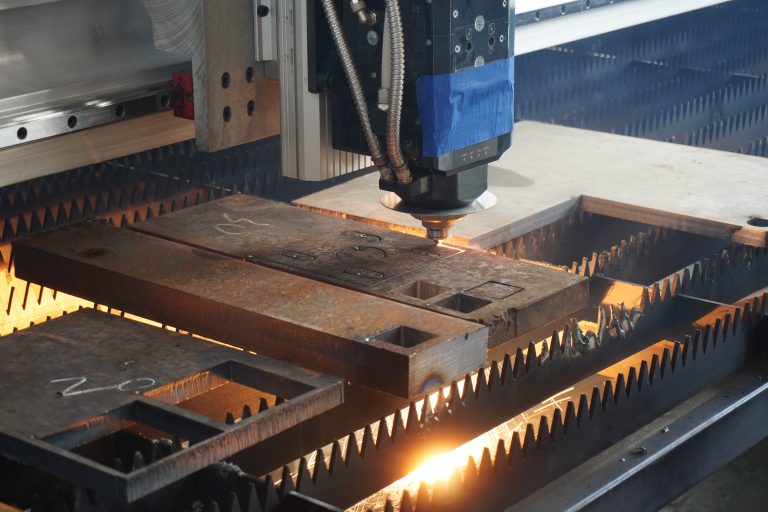

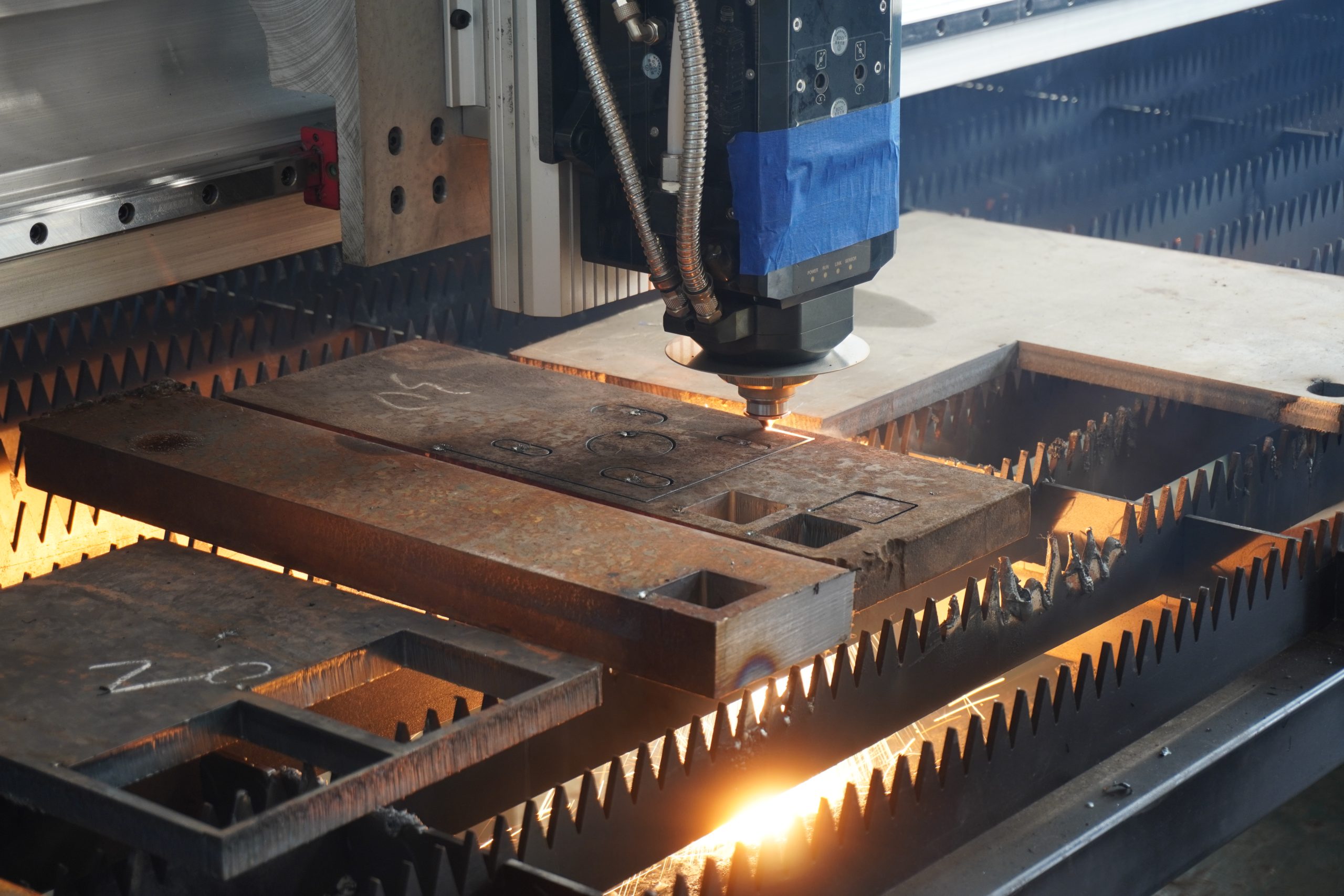

Stainless steel up to 4mm can be cut with laser cutting equipment, and carbon steel up to 20mm thick can be cut with a laser beam with oxygen, but a thin layer of oxidized film will form on the cutting surface after oxygen is added.

Because there is no tool processing costs, laser cutting equipment is also suitable for the production of previously unprocessable small quantities of various sizes of parts.

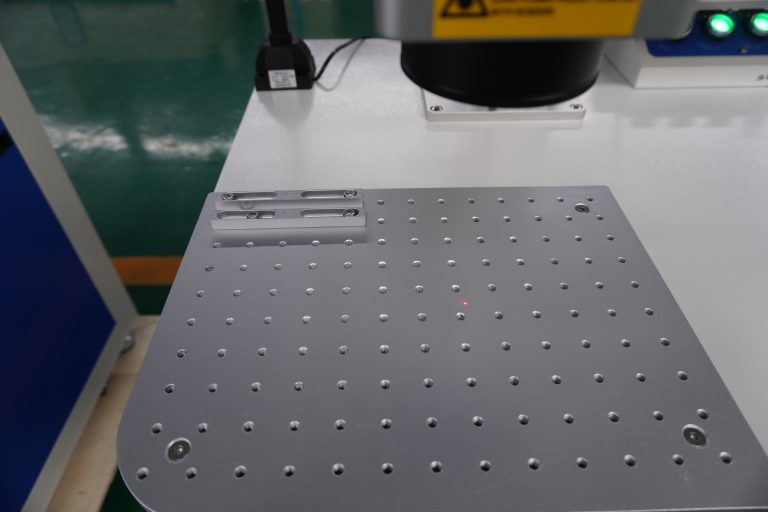

Laser cutting equipment usually utilizes a computer numerical control (CNC) unit, after which cutting data can be received from a computer-aided design (CAD) workstation over a telephone line.

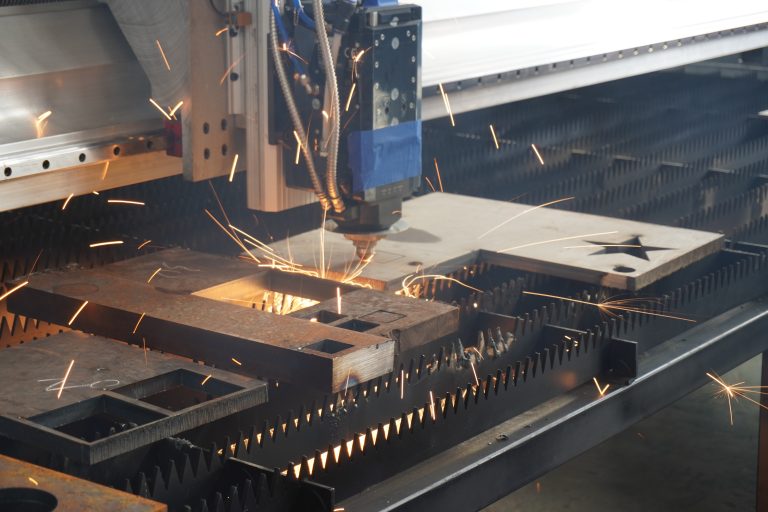

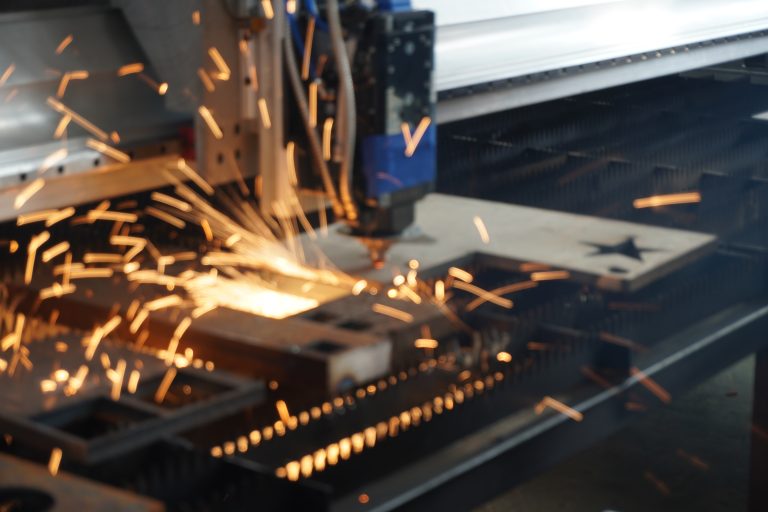

The principle of laser cutting is to irradiate the workpiece with a focused, high power density laser beam, causing the irradiated material to rapidly melt, vaporize, ablate or reach ignition. At the same time, a high-speed airflow coaxial with the beam blows away the melted material, thus cutting the workpiece. Laser cutting is one of the thermal cutting methods.

Characteristics of laser cutting technology

- High precision. Positioning accuracy of 0.05mm, repeat positioning accuracy of 0.02mm.

- Narrow slit. The laser beam is focused into a very small point of light, so that the focus reaches a very high power density, the material is very Shaanxi heating to the degree of gasification, evaporation and the formation of holes. With the beam and the material relative to the linear movement, so that the hole is formed continuously with a very narrow width of the slit. Cutting width is generally 0.10-0.20ram.

- Smooth cutting surface. The cutting surface is burr-free, and the surface roughness of the kerf is generally controlled within Ral2.5;A.

- Fast speed. Cutting speed up to 10m/min, the maximum positioning speed up to 70m/m/n, much faster than the speed of wire cutting.

- Good cutting quality. No contact cutting, the cutting edge is very little affected by heat, basically no thermal deformation of the workpiece, completely avoiding the collapse of the edge formed when the material is punched and sheared, the cut seam generally does not require secondary processing.

- No damage to the workpiece. The laser cutting head will not contact with the surface of the material to ensure that the workpiece is not scratched.

- Unaffected by the hardness of the material being cut. The laser can process steel plate, stainless steel, aluminum alloy plate, cemented carbide, etc. No matter what kind of hardness, deformation-free cutting is possible.

- Unaffected by the shape of the workpiece. Laser processing flexibility is good, can process any graphics, can cut tubes and other profiles.

- Non-metal can be cut and processed. Such as plastic, wood, PVC, leather, textiles and organic glass.

- Save investment in molds. Laser processing does not require molds, no mold consumption, no need to repair molds, saving time to replace molds, thus saving the processing costs, reducing production costs, especially suitable for the processing of large products.

- Save material. Using computer programming, can be different shapes of products for the whole sheet material sets cut, maximize the utilization of materials.

- Shorten the manufacturing cycle of new products. Trial production of new products, small quantities, the structure is uncertain, will change at any time, simply can not come out of the mold, laser cutting machine greatly shortens the new product manufacturing cycle, reducing the mold investment.

Classification of Laser Cutting

Laser cutting can be divided into four categories: laser vapor cutting, laser melting cutting, laser oxygen cutting and laser scribing and control fracture.

1) Laser vapor cutting

Heating the workpiece with a high energy density laser beam, so that the temperature rises rapidly, in a very short period of time to reach the boiling point of the material, the material begins to vaporize, the formation of steam. These vapors are ejected at high speed, while forming a cut in the material. Generally the heat of vaporization of the material is very large, so laser vapor cutting requires a lot of power and power density.

Laser vapor cutting is mainly used to cut very thin metal materials and non-metallic materials (such as paper, cloth, wood, plastic and rubber, etc.).

2) Laser melting and cutting

In laser cutting, the metal material is heated and melted by the laser, and then non-oxidizing gases (Ar, he, N, etc.) are is injected through a nozzle coaxial with the beam, and the liquid metal is discharged by the strong pressure of the gas to form a kerf. Laser cutting does not require complete vaporization of the metal, and the energy required is only 1/10 of that required for vapor cutting.

Laser cutting is mainly used for cutting some materials that are not easy to oxidize or active metals, such as stainless steel, titanium, aluminum and its alloys.

3) Laser Oxygen Cutting

The principle of laser cutting is similar to oxyacetylene cutting. It uses laser as a preheating heat source, oxygen and other active gases as cutting gas. On the one hand, the blown gas reacts with the cutting metal, causing an oxidation reaction and releasing a large amount of oxidizing heat; on the other hand, the molten oxides and melts are blown out of the reaction zone, forming a gap in the metal. Due to the large amount of heat generated by the oxidation reaction during the cutting process, the energy required for laser oxycutting is only 1/2 of that for melting cutting, and the cutting speed is much faster than that of laser vapor cutting and melting cutting. Laser cutting is mainly used for carbon steel, titanium steel, heat-treated steel and other easily oxidized metal materials.

4) Laser scribing and fracture control.

Laser scribing involves scanning the surface of a brittle material with a laser of high energy density, which causes the material to be heated and vaporized into small grooves, and then a certain amount of pressure is applied, and the brittle material will crack along the small grooves. The lasers used for laser scribing are typically Q-switched lasers and CO2 lasers.

Fracture control utilizes the steep temperature distribution produced by laser scribing to create localized thermal stresses in the brittle material, causing the material to fracture along the small grooves.

Applications of Laser Cutting

Most laser cutting machines are controlled by CNC programs or made into cutting robots. As a precision machining method, laser cutting can cut almost any material, including sheet metal in two or three dimensions.

In the field of automobile manufacturing, the cutting technology of roof windows and other space curves is widely used. Volkswagen of Germany uses a laser with a power of 500W to cut complex body sheets and various curved parts. In the field of aerospace, laser cutting technology is mainly used to cut special aerospace materials, such as titanium alloy, aluminum alloy, nickel alloy, chromium alloy, stainless steel, beryllium oxide, composite materials, plastics, ceramics, and should be time and so on. Aerospace parts processed by laser cutting include engine flame barrels, titanium alloy thin-walled magazines, aircraft frames, titanium alloy skins, wing long trusses, tail panels, helicopter main rotor blades, and space shuttle ceramic heat-insulating tiles.

Laser cutting and molding technology is also widely used in the field of non-metallic materials. It can not only cut high hardness and brittle materials, such as silicon nitride, ceramics, should time and so on. It can also cut and process flexible materials such as cloth, paper, plastic sheet, rubber, etc. If you use laser to cut clothes, you can save 10% ~ 12% of clothes and increase the efficiency more than 3 times.