Unloading is the initial and most important part of all sheet metal processing production. The production of all workpieces must first be unloaded, so the processing speed and quality of unloading has a crucial impact on the quality and production efficiency of the entire sheet metal workpiece.

At present, the sheet metal processing industry for the underfeed processing methods mainly include shear underfeed, punch press underfeed, cutting machine underfeed three.

Among them, the shearing machine has low processing cost and wide processing range, but it can only carry out horizontal and vertical simple cutting of the sheet, and cannot cut the internal features and complex shapes.

Punching machine processing high precision, but also can complete the shutters, convex package and other complex processing, is the shearer under the material and cutting machine under the material can not do the process; of course, to do these processes is the prerequisite for the mold is complete, and the general cost of the mold is higher, so only applies to large quantities of small parts of the processing and production.

Compared with the first two, the cutting machine under the material of high precision, high speed, suitable for various shapes of sheet metal processing, is currently the most widely used, the most comprehensive way of under the material, but also this post mainly want to discuss with you a material process.

Next, we will introduce sheet metal processing from the three angles of “Advantages of Laser Cutting”, “How to Reduce Production Costs by Design”, and “Laser Costing”, which are the most inquisitive. We will introduce laser undercutting, the leader in sheet metal processing, from three perspectives: “Advantages of laser cutting”, “How to reduce production costs by design”, and “Laser costing”.

CNC Laser Cutting

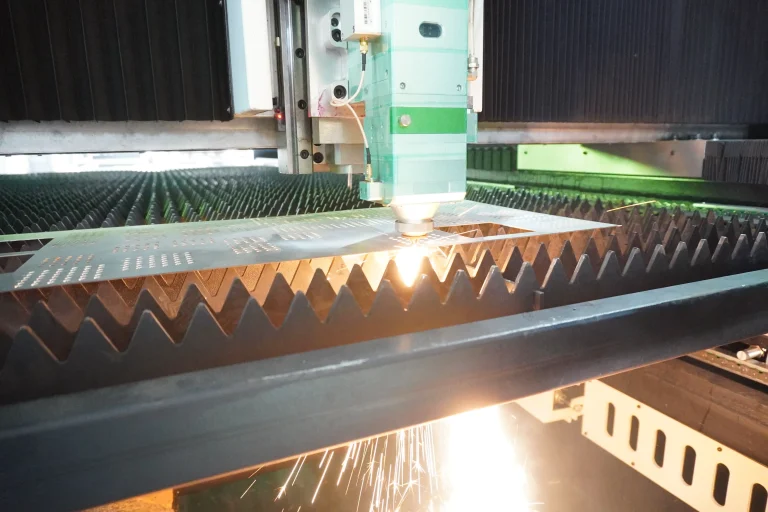

CNC laser cutting machine is a kind of thermal processing equipment that does not require direct contact with the workpiece. It irradiates a high energy density laser beam onto the workpiece through the laser head. When the powerful laser beam is focused on the metal, the heat density increases dramatically, causing the area on the workpiece irradiated by the ultra-fine focus spot to melt and vaporize instantly.

Compressed gas (air, oxygen or nitrogen) is then used to blow away any slag remaining on the workpiece. In this way, the laser cutter can cut the various shapes we need according to the computer instructions.

Advantages of laser processing

1.Fast cutting and low cost:

Undercutting was carried out using a Glorious fiber laser cutter with 6,000W of power, which can reach speeds of up to 120m/min!

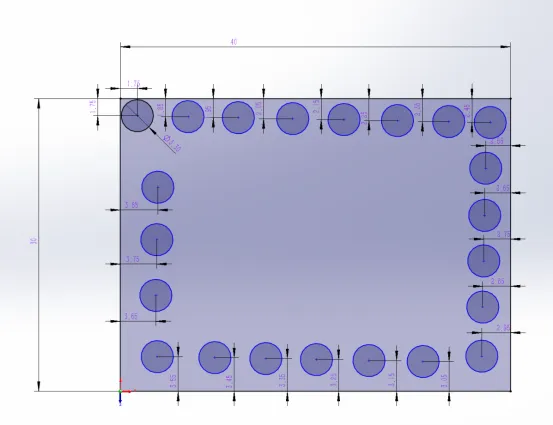

The total cutting length of the cut workpiece is 368mm, the feed speed is set to 100%, i.e. normal speed, and the total cutting time is about 20 seconds; even if the number of workpieces is increased to 100, it will only take about half an hour!

As the material does not need to be clamped and fixed during laser cutting, it saves both the jigs and fixtures and the auxiliary time for loading and unloading.

Of course, the absorption rate of laser is different for different metal materials, so the cutting speed is different for different materials under the same thickness.

At the same time, when the thickness of the material is not the same, there will be a difference in the time needed for perforation, so the same material in the cutting process, the thicker the thickness, the greater the laser energy needed, the slower the cutting speed.

If you cut the same shape of workpiece, the plate thickness increases and the cutting speed slows down.

Choosing the right material and thickness, where conditions allow, can also increase productivity and reduce the time cost of production!

Below is a table of cutting speeds for different plate thicknesses of both stainless steel and carbon steel for your reference:

6000W Laser Cutting Machine Cutting Speed

| Cutting Material | Cutting Thickness mm | Cutting Speed m/min | Cutting Material | Cutting Thickness mm | Cutting Speed m/min |

| Stainless Steel | 1 | 70-75 | Carbon Steel | 1 | 70-75 |

| 2 | 25-30 | 2 | 25-30 | ||

| 3 | 12-15 | 3 | 4.5 | ||

| 4 | 7.5-9 | 4 | 3.8 |

If the shape and characteristics of the processed workpiece are more complex, the length to be cut is as long as 172,641mm, but it takes only 3 minutes to place the material. It can be said that the cutting speed of the laser material is basically unaffected by the size of the cut and the complexity of the graphics, and no matter how complex the sheet metal processing is, the laser can quickly cut out the workpiece.

In addition, the biggest feature of the laser processing process is that it does not require the use of molds, no tool wear during processing, which can eliminate the use of a large number of molds, shorten the production time, reduce the cost of the product, which is very suitable for sampling products and batch product production.

Any processing industry, as a customer, what is the most concerned about the problem? It must be “how much money is needed for processing” and “when will the goods be delivered to me”. With laser processing, there is no need to open molds, and processing speed is fast, economical and efficient. If a workpiece requires only one process, it can even be shipped within 24 hours!

2.Good cutting quality and high precision

Due to the small laser spot, concentrated energy density and fast cutting speed, laser cutting is able to obtain better cutting quality.

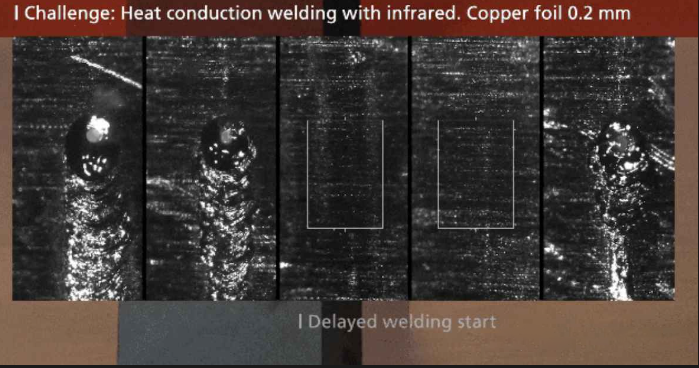

For example, the above several laser processing without any treatment of the workpiece cutting effect diagram, you can see, after our parameter adjustment, laser cutting out the side of the workpiece, in addition to micro-connections left behind the traces of the kerf is very smooth and flat; and hanging slag, burr problems can be almost negligible.

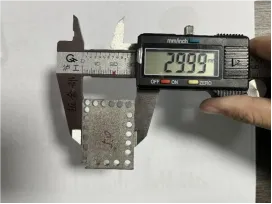

Then measure the tolerance of the inner and outer contour of the workpiece:

The drawing shows a workpiece length of 40mm, a width of 30mm and a bore hole diameter of 3.3mm;

And the cut workpiece is 40mm long, 29.99mm wide and 3.26mm hole diameter; the error is within 0.1mm. According to our so long time verification, laser undercutting accuracy can be stabilized at ±0.1mm, that is, within 10 silk. This is a very high precision compared to other doweling processes!

Strengths Summary:

- Fast laser processing speed, greatly improve the production efficiency of the workpiece, reduce the production cycle of the product; under normal circumstances, the flat workpiece can even realize the delivery within 24 hours!

- Low cost of laser processing, no “tool” wear, no need for molds can be processed production, eliminating the production cost of molds and the time cost of replacing molds.

- laser processing quality is good, the cut is smooth and flat, burrs and slag problems can also be easily solved by subsequent processes.

- high precision laser processing, internal and external contour tolerance can be stabilized within 0.1mm.

Materials and types of support

1.Materials Supported for Processing

The high energy density of the laser beam of the CNC laser cutting machine is sufficient to melt most organic and inorganic materials, which is especially suitable for metal materials including aluminum, alloy steel, stainless steel and other materials that are difficult to process due to brittleness, hardness and high melting temperature, and it has the advantages of high energy density, short action time, small heat-affected range, small deformation and so on.

However, for materials with high reflectivity, such as gold, silver, copper, etc., it is difficult for laser cutting machines to cut them because they are good heat transfer conductors with low absorption of the beam.

2.Supported types of machining

Through the CNC mechanical system to move the spot irradiation position, to realize automatic cutting. The addition of numerical control makes the laser cutting machine has a high degree of automation, processing speed, high processing accuracy; because you can define your own platoon under the workpiece according to the actual needs, cnc laser system is very suitable for personalized processing, especially certain sheet metal parts with complex geometry of the small batch production.

Of course, when a laser cutting machine cuts thicker plates, it moves slower than a punch press; non-mechanical contact processing cannot produce features such as convex packages, knock-out holes, shutters, countersunk holes, or taps in sheet metal; and the potential for deformation is extremely high in laser cutting when cutting perforated and reticulated plates. Therefore, CNC laser cutting machines are generally used to process thin plate type, 2D dimensional, non-intensive workpieces.

Punching equipment is used when thicker, with features such as convex bags and shutters, as well as perforated and mesh plates, need to be processed.