Laser welding, as an efficient joining technology, has been widely used in several fields in recent years, especially in the industries of automobile manufacturing, aerospace, medical equipment and precision instrument manufacturing. The latest technological advances are mainly focused on improving welding quality, enhancing process adaptability and expanding the range of applications.

1.Applications for blue lasers:

For the welding of highly reactive materials such as copper and aluminum, blue lasers are able to achieve clean welds at lower power due to their higher absorption on these materials than infrared lasers.

Blue light semiconductor lasers continue to drive a change in the way highly reflective materials such as copper and aluminum are processed. The high absorption rate of blue light on highly reflective metals compared to infrared light brings great advantages for traditional industrial applications such as cutting and welding. The shorter wavelength and lower penetration depth of blue light compared to infrared light also make it possible to use blue light in innovative areas such as thin film processing. In addition to materials processing, blue light is also attracting attention for applications in medical, lighting, pumping, and consumer applications.

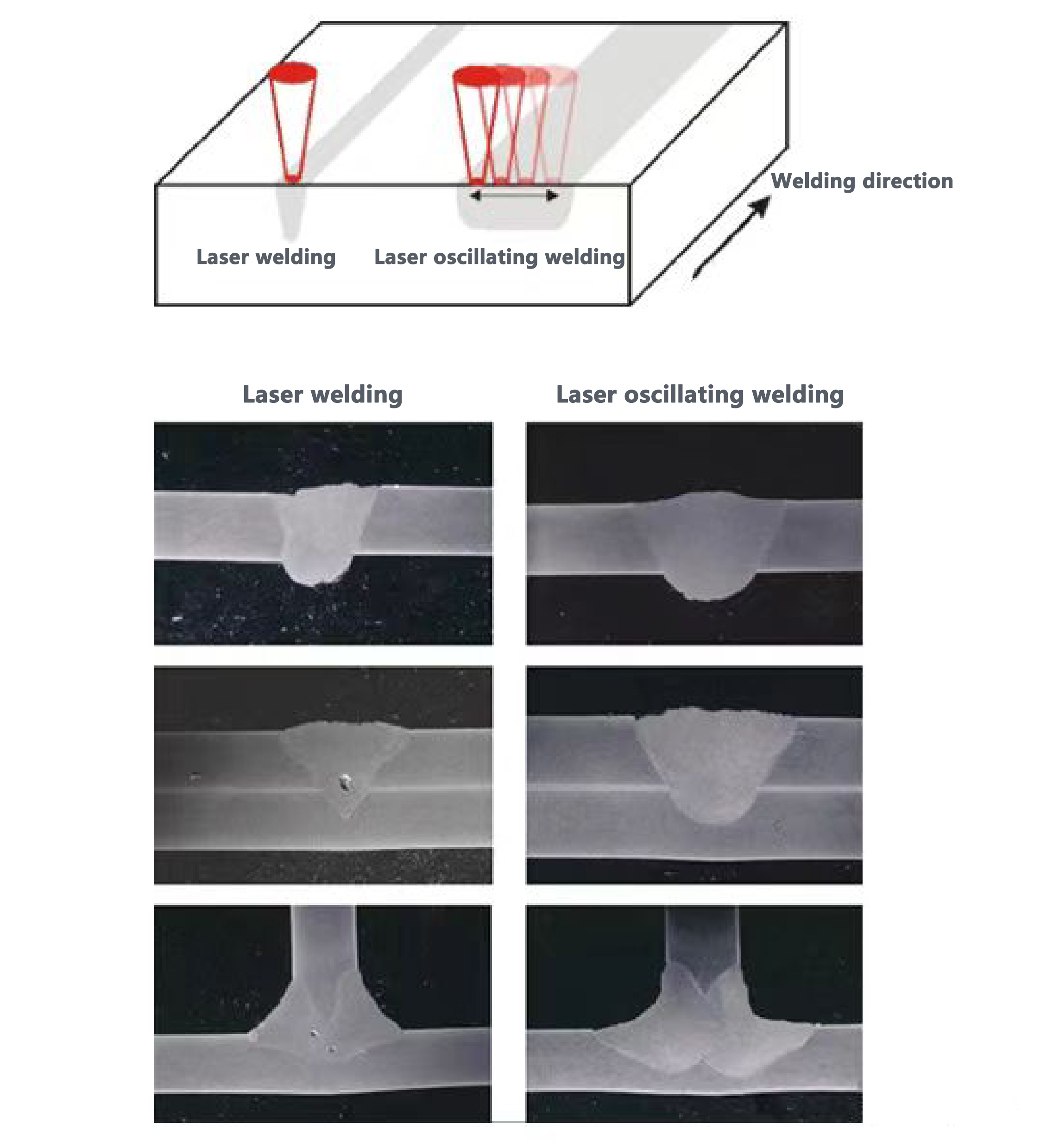

2.Oscillating welding technology:

The oscillation of the beam by means of a laser-specific oscillating welding head not only expands the processing range, but also improves the tolerance of the weld width, thus improving the quality of the weld.

- Oscillating Welding Advantages

- Larger oscillating spot size helps bridge larger gaps

- Lower required tolerances and fewer welding consumables reduce processing costs

- Weld times reduced to one-tenth of a second for increased weld throughput

- Reduces or eliminates time spent straightening weldments, increasing productivity

- Reduced part distortion and improved equipment quality

- Welding of dissimilar materials (steel to cast iron, stainless steel to inconel, etc.)

- Low spatter for crack-prone welding materials

- Significant reduction of post-processing (cleaning, grinding ……)

- Great freedom of part design

3.Dual-focus laser welding:

Studies have shown that the dual-focus laser welding method is more stable and controllable than the traditional single-focus method, reducing keyhole fluctuations and improving the stability of the welding process.

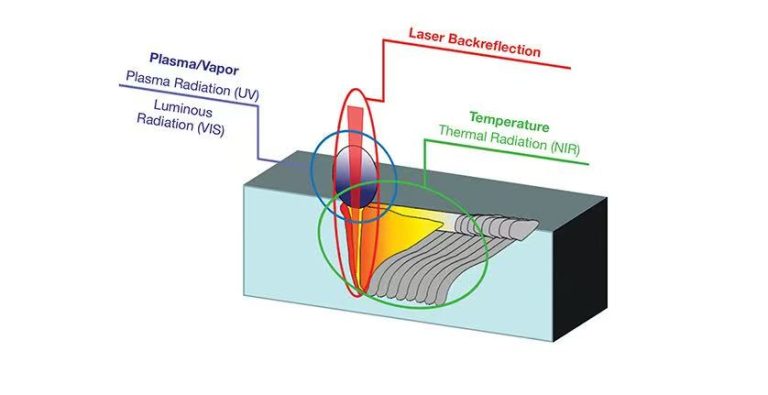

4.Welding process monitoring technology:

Using coherent interferometric imaging technology, a new monitoring system for the entire welding process has been developed, which is able to adapt to changes in keyhole geometry for different processes, providing accurate depth measurement and customized monitoring solutions for the welding process.

5.Diversification of Laser Welding Heads:

With the development of technology, various types of laser welding heads have been introduced according to the functions and needs, including high power welding heads, laser galvanometer scanning heads, welding oscillating heads, etc., to adapt to different welding needs.