When it comes to joining metals, there are plenty of methods out there — from traditional arc welding to newer technologies like friction stir and electron beam. But in recent years, laser welding has really stood out as a go-to solution across industries.

Why?

Because it’s fast, precise, repeatable, and can handle everything from tiny micro welds to thick structural joints. In this article, I’ll walk you through the top 10 reasons why laser welding is not just another option — it’s often the best one.

- Works with a Wide Range of Materials

One of the biggest advantages of laser welding is its versatility when it comes to materials.

You can use it on common metals like stainless steel, titanium, and nickel alloys — but also on more challenging ones like copper and aluminum. These materials are highly reflective, which makes them tough to weld using conventional methods.

With laser welding, those challenges become manageable. And if you’re working with dissimilar metals — say, aluminum to copper — the laser gives you control over heat input and penetration, making the process much more reliable than other techniques.

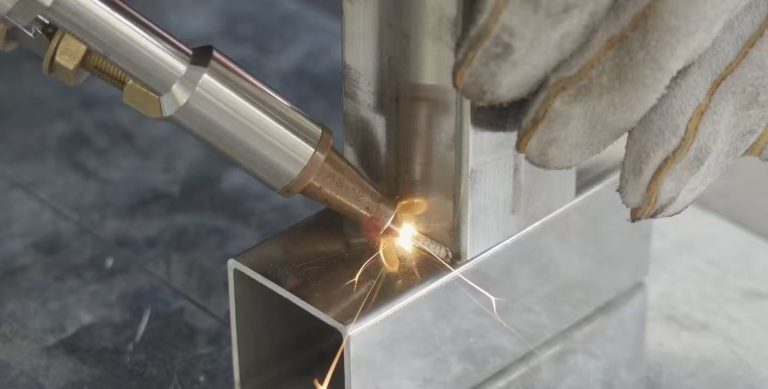

- Perfect for Micro-Welding Applications

If you’re working in industries like medical devices or microelectronics, precision is everything.

We’ve used laser welding to join components as small as microfluidic chips and surgical tools. Because the laser beam can be focused down to a very fine point, we’re able to make extremely small, clean welds without damaging surrounding areas.

This kind of precision isn’t possible with most traditional welding processes.

- Handles Thick Sections Too

Don’t let the word “laser” fool you into thinking it’s only good for thin or delicate parts.

With the right power level and setup, lasers can weld materials up to half an inch thick. That makes them suitable not just for fine electronics, but also for heavy-duty industrial applications like automotive frames or aerospace structures.

So whether you need a hairline seam or a deep structural joint — laser welding can do both.

- Highly Repeatable Process

Once you get your parameters dialed in, laser welding is incredibly consistent.

We’ve had customers come back after months and ask for the same weld again — and we can reproduce it exactly because the process is so repeatable. This is huge for production runs where quality control matters.

In fact, once set up properly, the system can run with minimal human intervention, giving you peace of mind that every part will meet the same standard.

- Precision You Can Control

Laser welding gives you tight control over where the energy goes.

Unlike arc welding, which spreads heat over a wider area, the laser lets you focus the beam precisely where you want it. That means smaller heat-affected zones (HAZ), less distortion, and better preservation of the material’s original properties.

And because it’s a non-contact process, there’s no tool wear or contamination — just clean, accurate results.

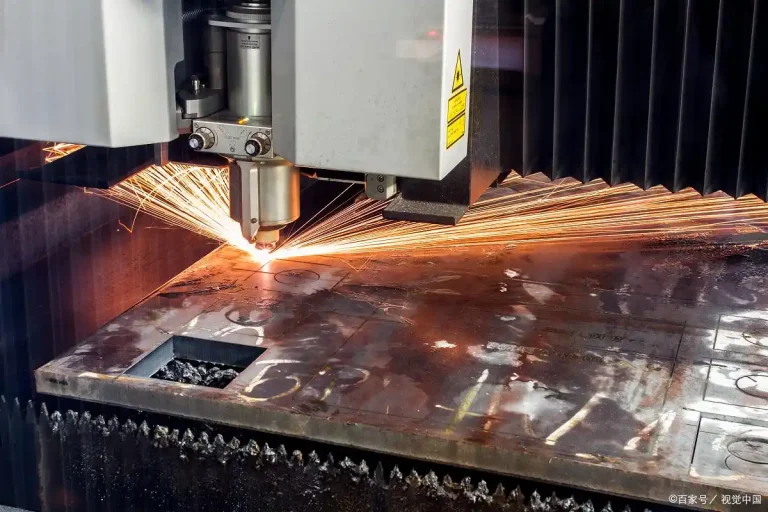

- Speed That Makes a Difference

Time is money — and laser welding saves a lot of it.

Where TIG welding might take hours to complete a complex joint, a laser can finish the job in minutes. The speed of the laser head can reach hundreds or even thousands of millimeters per minute, depending on the application.

This speed doesn’t come at the expense of quality either. You still get strong, clean welds — just faster.

- Low Heat Input = Less Damage

Excessive heat during welding can warp parts, change material properties, or damage nearby components.

That’s where laser welding shines. It delivers heat in a controlled, localized way — keeping the rest of the part cool and undisturbed.

This is especially useful when you’re welding around sensitive electronics or internal components that can’t tolerate high temperatures.

It also reduces residual stress in the material, meaning fewer cracks and less need for post-weld treatments.

- Flexible with Part Size

Whether you’re working on a small prototype or a large-scale industrial component, laser welding adapts well.

You can operate in open air or inside a glove box for controlled environments. And with higher-powered lasers, even large or bulky parts can be welded effectively.

There’s no strict size limitation — just the right amount of power and the proper fixturing.

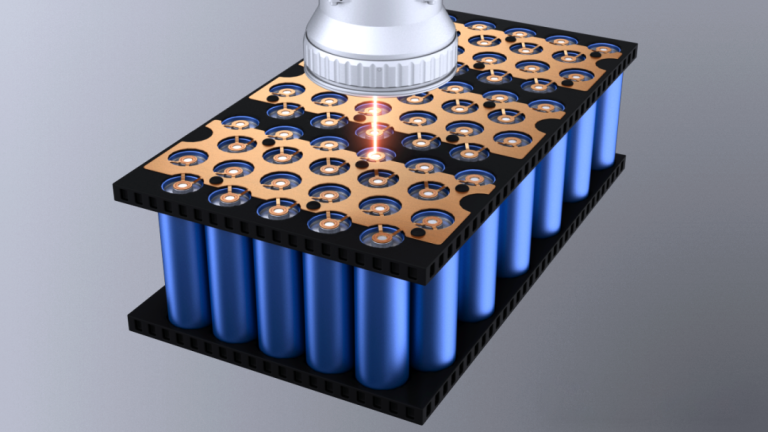

- Easy to Integrate with Automation

Lasers have been around long enough that they play nicely with automation systems.

From CNC platforms to robotic arms, integrating a laser welder into an existing production line is straightforward. In fact, many modern setups are built around the idea of robot-assisted laser welding.

The technology is mature, and the software support is solid — making it easier than ever to automate your welding process.

- Cost-Effective in the Long Run

While the initial investment in laser equipment might be higher than some traditional methods, the long-term savings speak for themselves.

Faster cycle times, reduced rework, and minimal consumables all add up. Plus, the repeatability and consistency mean fewer defects and less waste.

So yes, laser welding may cost more upfront — but it pays off quickly through improved productivity and quality.

Final Thoughts

Laser welding isn’t just a trend — it’s a powerful, flexible, and efficient solution that’s changing how we approach metal joining.

From micro-devices to large structural parts, from reflective metals to dissimilar alloys — it does more than most people expect. And when you factor in the speed, precision, and cost benefits, it’s easy to see why more and more manufacturers are making the switch.

If you’re looking for a welding method that delivers real value, laser welding is definitely worth a closer look.