During the welding of factory titanium tubes, the depth of the weld seam is determined by the thickness of the titanium tube.

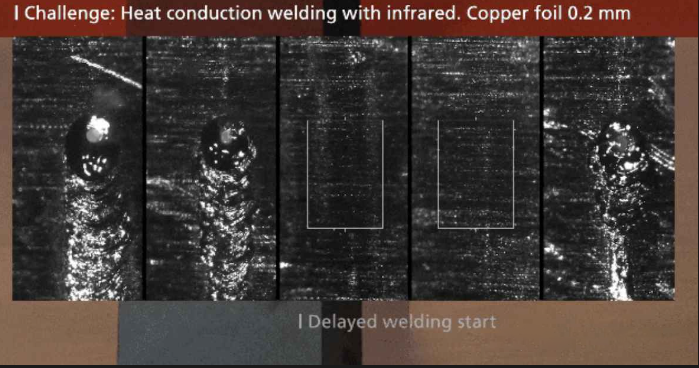

The production goal is therefore to improve formability by reducing the weld seam width and at the same time achieving higher speeds. When selecting the most suitable laser, not only the beam quality but also the precision of the tube rolling machine must be taken into account.

In addition, the limitations encountered in reducing beam spot size must first be considered before dimensional errors in the rolling machine come into play.

There are many unique size-related issues associated with welding titanium tubing, but the main factor affecting the welding process is the weld seam on the weld box.

Once the titanium plate is formed and ready to be welded, the weld seam is characterized by gaps between the titanium plates, severe or slight weld misalignment, and variations in the centerline of the weld. This gap determines the amount of material required to form the molten pool.

Excessive pressure can result in excess material at the top or inside diameter of the titanium welded pipe. On the other hand, severe or minor weld misalignment can result in a poor weld appearance.

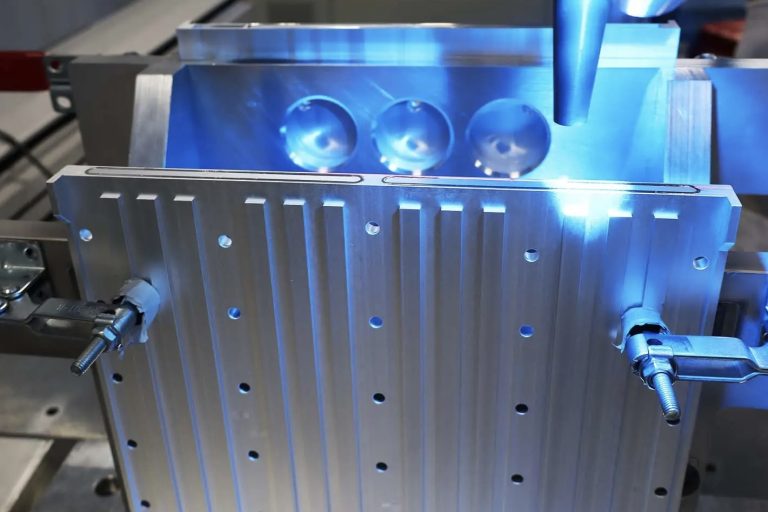

In both cases, the titanium sheet is cut and cleaned, rolled up, and brought to the welding point. In addition, coolant is used to cool the induction coils used in the heating process.

Finally, some coolant is used during the extrusion process. Here, a high force is applied to the extrusion rollers to avoid porosity in the weld area; however, the use of higher extrusion pressures may result in increased burrs (or weld passes). Therefore, specially designed tools are required to remove burrs from both the inside and outside of the tube.

One of the main advantages of the HF welding process is the ability to machine titanium tubing at high speeds. However, a typical situation with most solid phase forging is that the weld joints of high frequency welding cannot be easily and reliably tested using conventional non-destructive techniques.

Weld cracks may appear in thin flat areas of low strength joints that cannot be detected by conventional methods, which may affect the reliability of certain demanding automotive applications.

Traditionally, titanium tube manufacturers have chosen to complete the welding process using gas tungsten arc welding (GTAW), which creates a welding arc between two non-self-consuming tungsten electrodes.

At the same time, an inert shielding gas is introduced from the torch to protect the electrodes, generating an ionized plasma stream and protecting the weld pool.

It is a proven and easily understood process that consistently delivers high quality welding results. The success of the titanium tube welding process therefore depends on the integration of all the individual technologies and needs to be treated as a comprehensive system.

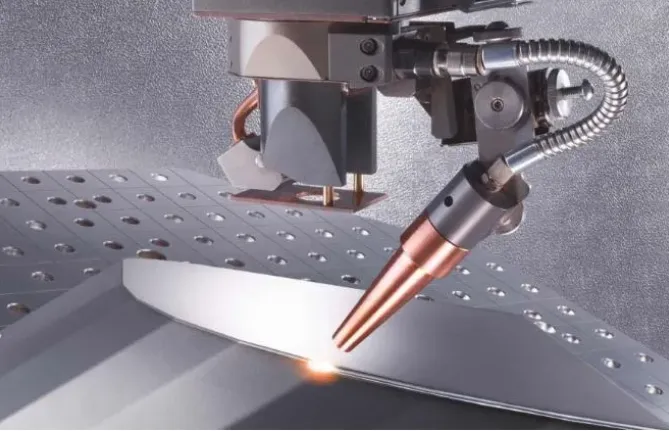

In all titanium tube welding applications, the edges of the titanium sheet melt and solidification occurs when the edges of the titanium tube are squeezed together using clamping brackets. However, laser welding is characterized by its high energy beam density.

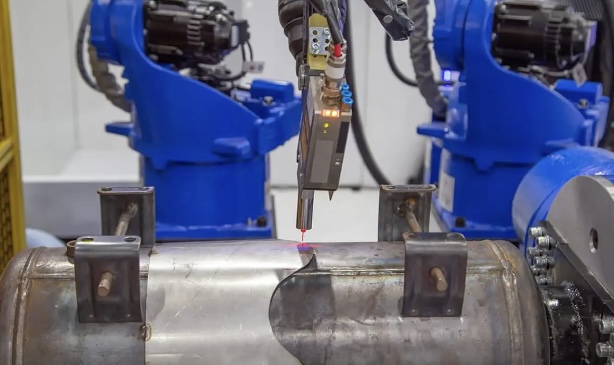

The laser beam not only melts the surface of the material, but also creates small holes, resulting in a narrower weld profile. To weld a titanium tube, a flat titanium plate is first formed and then molded into a cylindrical tube.

Once formed, the seam of the titanium tube must be welded together. This seam significantly affects the formability of the part. Therefore, choosing the right welding technique is critical to obtaining a weld profile that meets the rigorous testing requirements of the manufacturing industry.