When laser cutting medium carbon steel (S45C), tool steel (SK), and other materials, understanding their characteristics and adopting appropriate processing strategies is crucial. These materials have a higher carbon content, although the silicon and manganese levels are similar to SS400, presenting unique challenges during the cutting process. Proper management of the relationship between output power and speed, handling the heat-affected zone, and considering the impact on subsequent processing steps are all key to ensuring high-quality cuts.

Phenomenon

These materials are characterized by the fact that the silicon (Si) and manganese (Mn) content contained in the material, which affects the cutting quality, is close to that of SS400, but the carbon (C) content is relatively high. In general, the material is very strict in the management of composition standards, basically there will be no processing performance due to the phenomenon of different batch number and there are differences. The correlation between output power and speed under machining conditions is basically the same for medium carbon steel as for SS400. When piercing, carbon will be burned and splashed with bright sparks, but it will not lead to overheating.

Principle and Precautions

S45C and SK materials are hardened materials, and in laser cutting, the fire layer will show up around the cut. When laser cutting parts that require hardening heat treatment after cutting, the heat treatment step can be eliminated. This feature of laser cutting can be utilized to shorten the overall processing time by saving the time for heat treatment after laser cutting.

However, there is also a dislike of the material being quenched in processing. One example is the processing of a round hole that needs to be threaded after laser processing. The cutting surface will be hardened by laser cutting, and the hardened cutting surface will be even harder than the cutting edge for threading, making threading impossible. There is currently no effective solution to this problem, and methods other than laser cutting need to be tried.

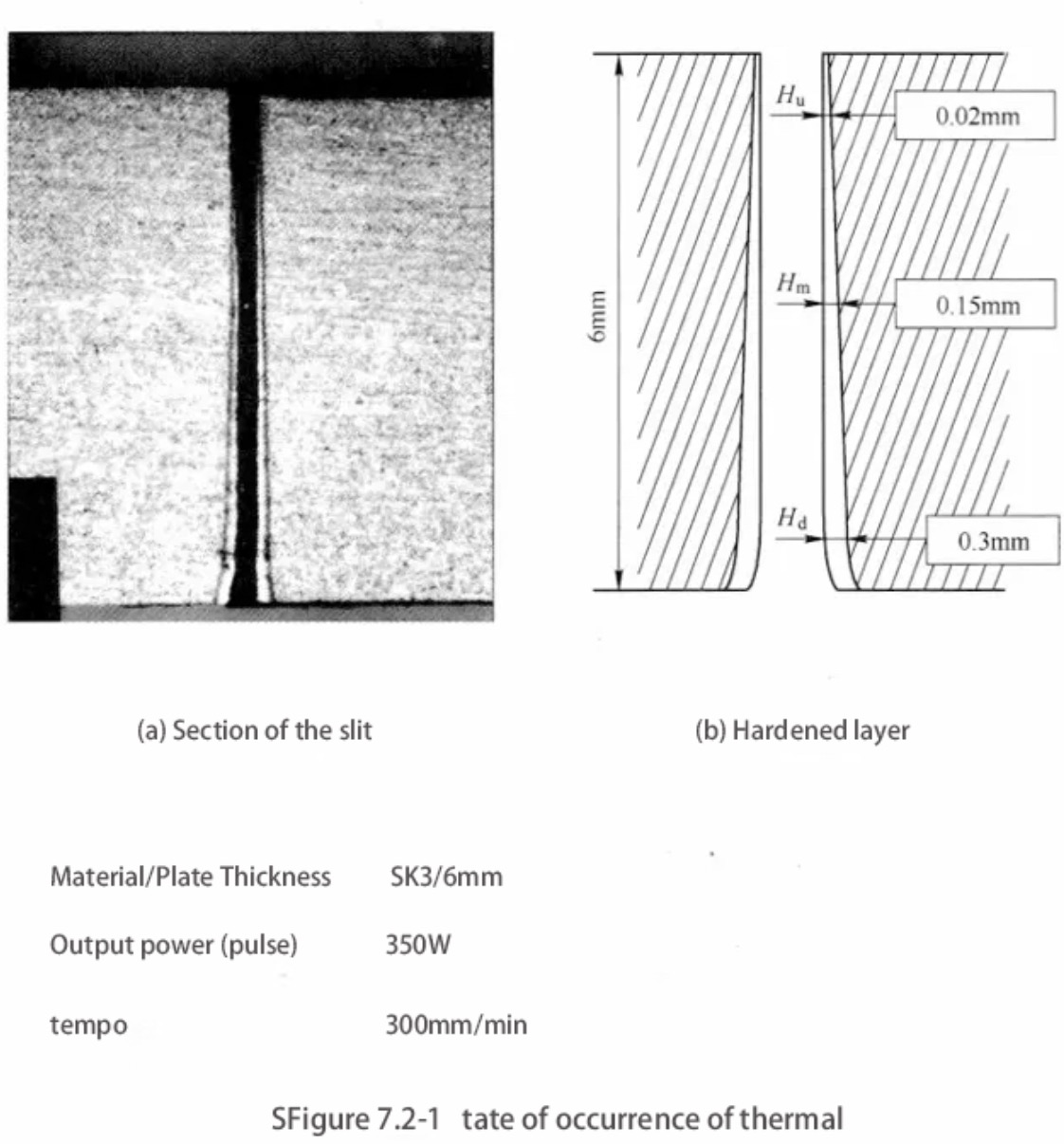

Figure 7.2-1 shows the state of the heat-affected layer around the kerf. In the upper part of the slit, the heat-affected layer is narrower because the molten metal is pushed down quickly and the heating time is very short. And the further downward, the longer the retention time of the molten metal, the wider the width of the heat-affected layer. The hardening of the heat-affected layer around the cut requires rapid cooling of the heated part after cutting. The cooling of laser cutting is self-cooling by heat transfer from the heated part to the interior of the object to be processed.

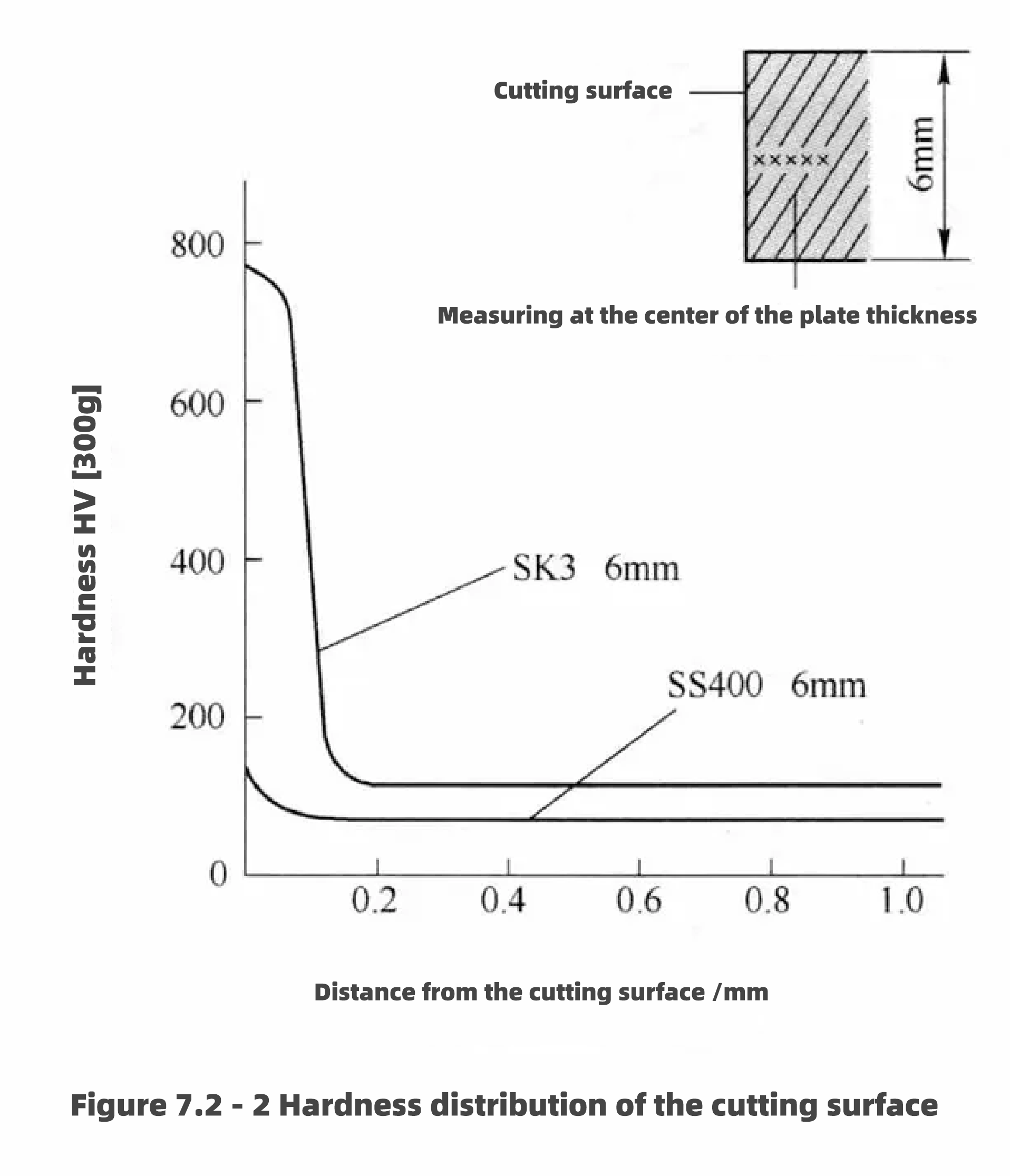

To reduce heat delivery to the machined part and to narrow the width of the heat-affected layer, pulse cutting conditions can be used. Figure 7.2-2 shows the relationship between hardened layer width and hardness distribution. As influenced by pulse frequency and peak pulse power, the lower the frequency and the higher the peak pulse, the narrower the hardened layer will be.

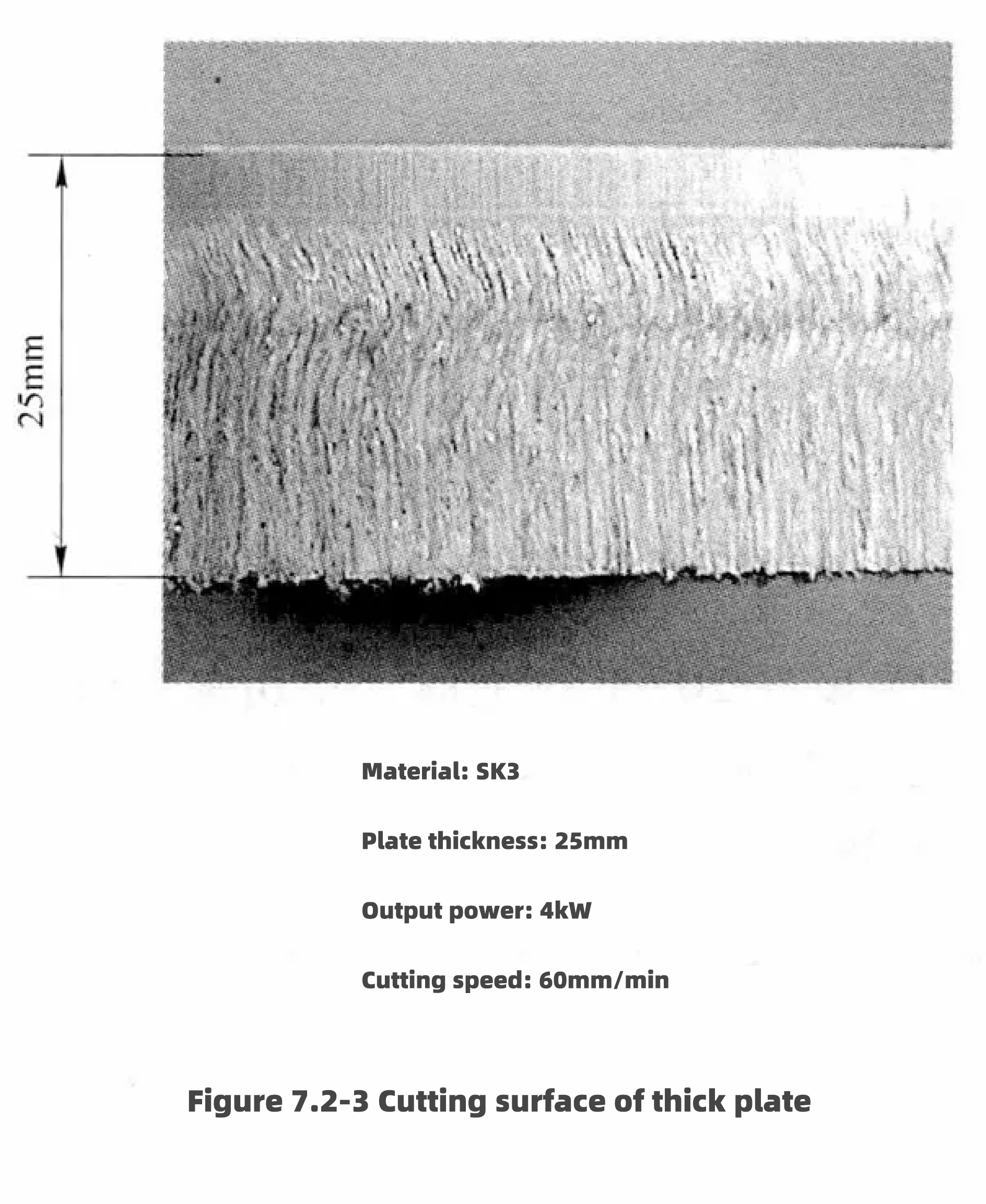

When the thickness of the material is 20 mm or more, oxidation-free cutting with nitrogen can effectively suppress overburning. Figure 7.23 shows the cutting surface of a 25 mm thick SK plate cut with 4 kW output power. The cutting speed condition is a low speed of 60mm/min.

In conclusion, laser cutting of medium carbon steel and tool steel requires particular attention to their quenching characteristics and the impact on subsequent processes such as tapping. By optimizing pulse cutting conditions or employing nitrogen-based non-oxidation cutting methods, it is possible to effectively reduce the width of the heat-affected zone and improve cutting quality. Selecting appropriate cutting parameters not only enhances production efficiency but also ensures the superior performance of the final product.