Phosphate layer is a common surface treatment. Phosphate layer plays a vital role in rubber-metal bonding, not only improving bond strength and corrosion resistance, but also helping to improve chemical compatibility and promoting physical adsorption of the adhesive, thus ensuring the performance and quality of the bonded product.

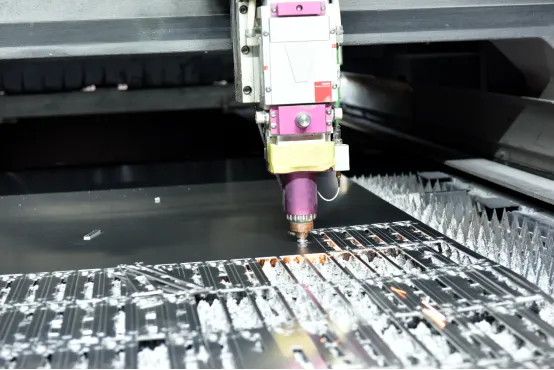

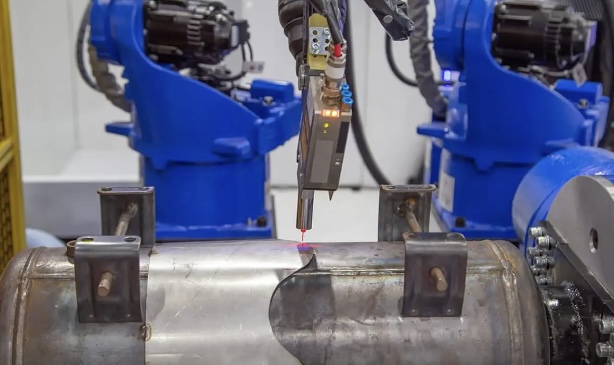

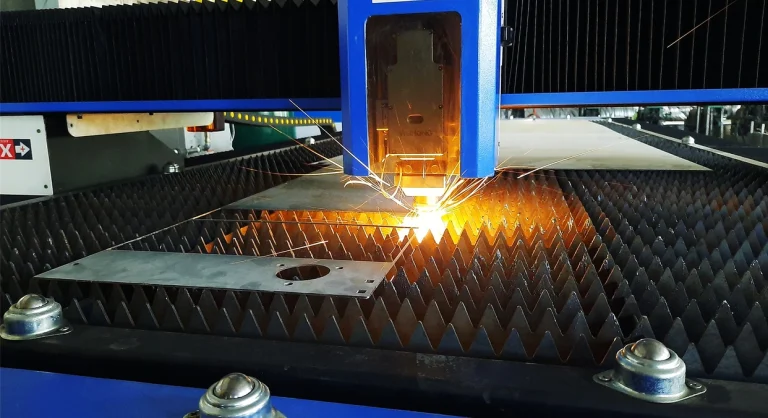

In the laser welding process, the presence of a phosphide layer may adversely affect the quality of the weld, leading to some specific defects. The following is a detailed description of the defects that may be caused by the phosphide layer in laser welding, as well as their causes and solutions.

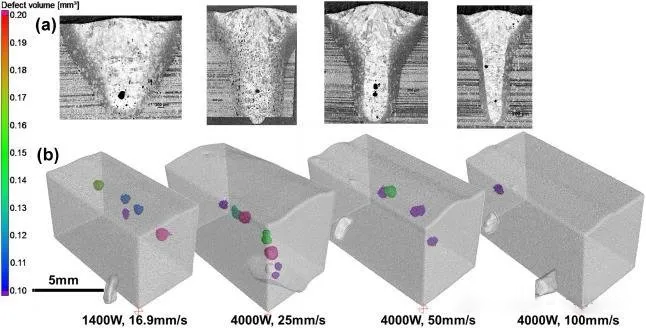

- Porosity defects

Porosity defects may occur in the laser welding process of phosphide layers. This is because the phosphide layer decomposes at high temperatures, releasing gases (e.g., phosphine) that may form bubbles in the molten pool, which may become trapped in the weld as the welding process progresses, forming porosity.

Solution:

- Thoroughly clean the surface of the workpiece before welding to remove the phosphate layer.

- Adjust welding parameters, such as reducing the welding speed and increasing the flow of shielding gas to help the gas escape.

- Use blowing or vacuuming devices to reduce the gas content in the molten pool.

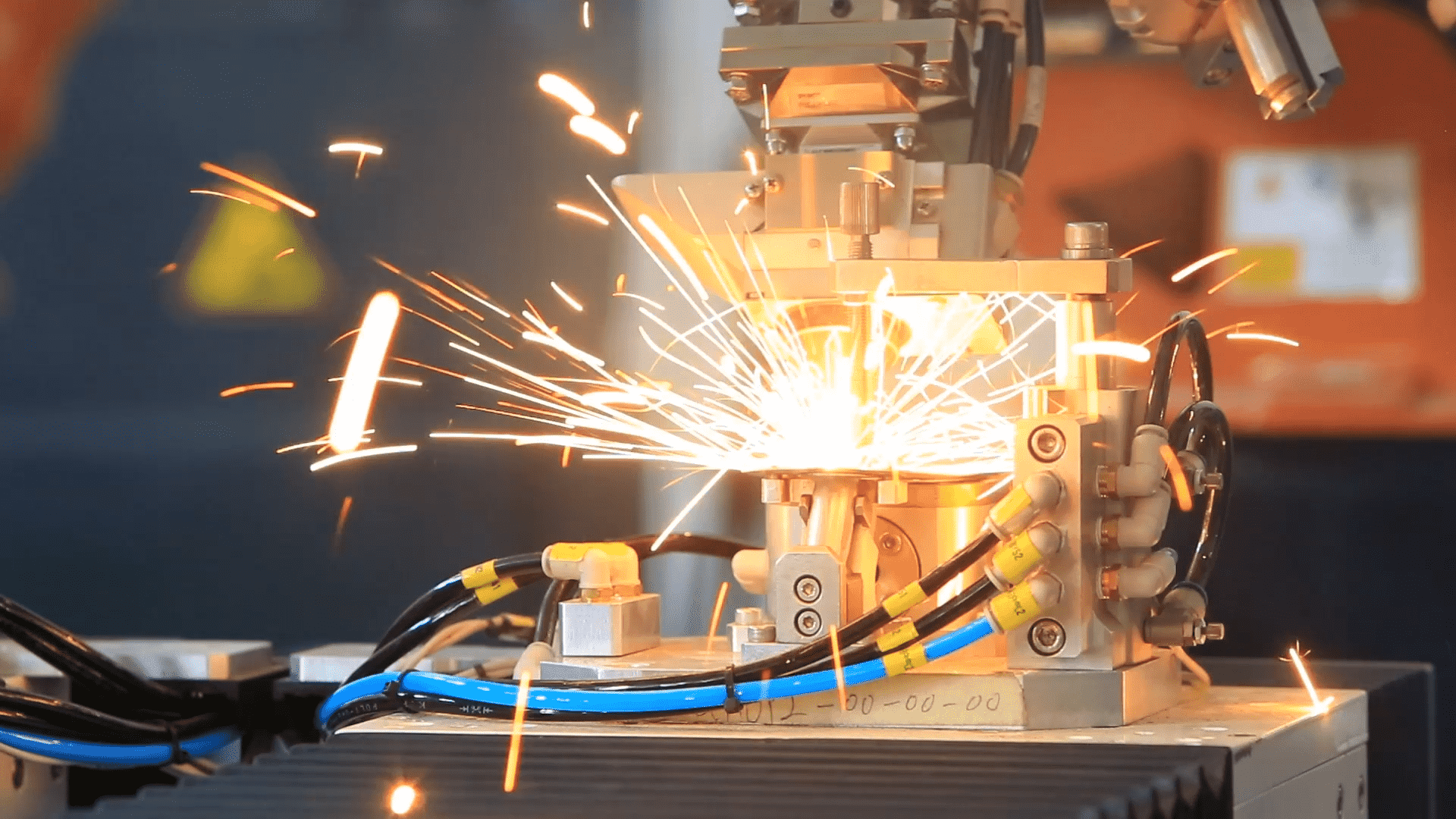

- Spattering

The presence of a phosphate layer may increase spattering during the welding process. Spatter not only affects the surface quality of the weld, but can also damage the laser welding head and protective lenses.

Solution:

- Remove the phosphate layer using appropriate surface pretreatment methods such as chemical cleaning or mechanical polishing.

- Optimize laser parameters, such as power and speed, to reduce spattering.

3. Uneven welds

The phosphating layer may cause uneven distribution of the weld metal. Since the heat transfer properties of the phosphating layer are different from those of the base material, the heat distribution during the welding process may be uneven, resulting in poor weld formation.

Solution:

- Ensure that the phosphate layer is completely removed before welding.

- Use uniform laser beam distribution for more uniform heat input.

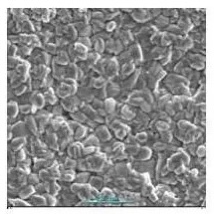

- Reduced performance of welded joints

The phosphorus element in the phosphide layer may react with the metal during the welding process to form a brittle phase, reducing the mechanical properties of the welded joint.

Solution:

- Use appropriate welding materials and processes to minimize the effect of the phosphide layer on the performance of welded joints.

- Perform post-weld heat treatment to improve the microstructure and properties of welded joints.

- Pollution during welding

The decomposition of the phosphating layer during welding may produce harmful gases and solid particles, which may pollute the operator’s health and the environment.

Solution:

- Provide good ventilation in the welding area to minimize the accumulation of harmful gases.

- Protect operators from contamination by using appropriate personal protective equipment.

- Poor surface quality of welds

The presence of phosphating layer may lead to unevenness and oxidized discoloration on the surface of the weld, affecting the beauty and corrosion resistance of the weld.

Solution:

- Perform thorough surface treatment before welding to ensure that the phosphating layer is removed.

- Use appropriate welding techniques and parameters to obtain better weld surface quality.

Conclusion

The phosphide layer may cause a variety of defects in laser welding, affecting weld quality and joint performance. The adverse effects of phosphating layer on laser welding can be effectively reduced by appropriate surface pretreatment, optimization of welding parameters and adoption of auxiliary technology. Thorough cleaning before welding and precise control during welding are the keys to ensure the welding quality.