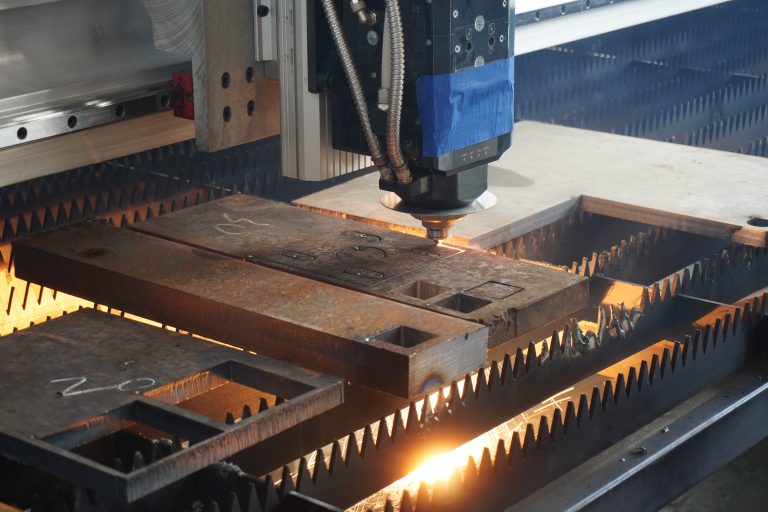

Laser cutting down requires two steps to realize – piercing and cutting. Only by ensuring good and stable perforation results can the cutting process continue to the next step. Especially thick plate piercing is prone to burst hole phenomenon, resulting in unstable cutting, lens and nozzle damage and other problems. Therefore, excellent piercing is the first step to obtain good sample results while processing stably.

At present, Glorious laser 30000W laser has been able to achieve 50mm, 60mm carbon steel stable perforation and cutting, stable performance of the laser is naturally indispensable, and superb operation process is also indispensable. Today, we will Glorious engineers after nine hundred and ninety-one tests summarized by the thick plate perforation experience to the public.

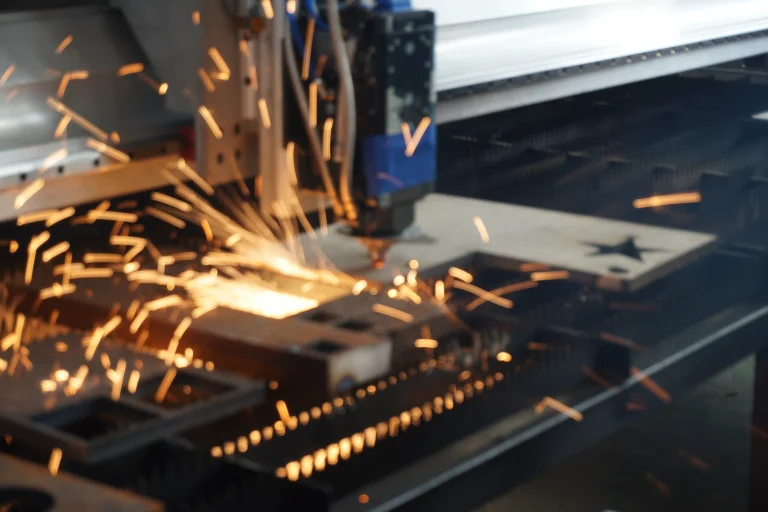

Pulsed perforation method

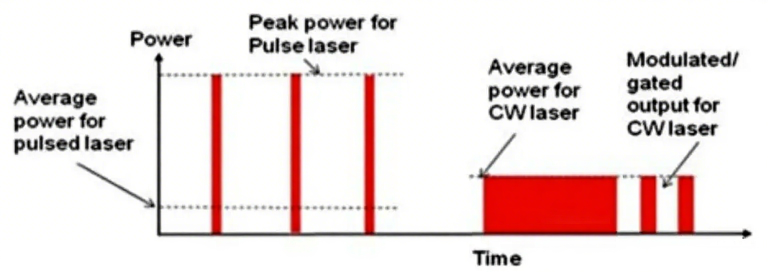

Fiber laser cutting generally adopts high peak power pulse laser mode, so that a small amount of material melting, carbon steel cutting commonly used oxygen as an auxiliary gas, each pulse laser will produce a smaller particle jet, gradually deeper, so that the diameter of the perforation is smaller, less slag sprayed up, and smoother cutting start. The pulse perforation method must have a better gas control system to realize the fine control of gas type and gas pressure.

Reasons for bursting

In the perforation process, often encountered burst hole phenomenon, as shown below 30mm carbon steel perforation occurred when the burst hole, there may be the following reasons:

- The pulse duty cycle is large;

- Perforation air pressure is set too large;

- Perforation pulse frequency is too high;

- Multi-stage perforation, no stop light blowing or blowing time is too short;

Burst hole solution

1. pulse duty cycle is large:

| Parameter | Peak Power | Duty Cycle | Pulse Frequency | Focus Point | Gas Pressure | Light-off Blowing Time |

|---|---|---|---|---|---|---|

| Punch Hole Parameters | 100% | 80% | 500Hz | -6mm | 1bar | 200ms |

| Optimized Parameters | 100% | 50% | 500Hz | -6mm | 1bar | 200ms |

2.The perforation air pressure is set too high:

| Parameter | Peak Power | Duty Cycle | Pulse Frequency | Focus Point | Gas Pressure | Light-off Blowing Time |

|---|---|---|---|---|---|---|

| Punch Hole Parameters | 100% | 50% | 500Hz | -6mm | 2bar | 200ms |

| Optimized Parameters | 100% | 50% | 500Hz | -6mm | 1bar | 200ms |

3.The perforation pulse frequency is too high:

| Parameter | Peak Power | Duty Cycle | Pulse Frequency | Focus Point | Gas Pressure | Light-off Blowing Time |

|---|---|---|---|---|---|---|

| Punch Hole Parameters | 100% | 50% | 5000Hz | -6mm | 1bar | 200ms |

| Optimized Parameters | 100% | 50% | 500Hz | -6mm | 1bar | 200ms |

Perforation method guidance

- Peak power as high as possible, can improve the piercing efficiency;

- To ensure that the laser spot will not hit the nozzle under the premise that the piercing focus is appropriately lowered;

- Oxygen perforation air pressure and cutting air pressure is equivalent;

- Multi-stage perforation between the increase in the stop light blowing, not easy to burst the hole.

In conclusion, achieving efficient and stable piercing requires not only high-performance laser equipment but also precise operational techniques and correct parameter settings. By properly adjusting pulse frequency, gas pressure, and focus position, you can effectively prevent blowouts, improve processing quality, and enhance efficiency. We hope that the guidelines provided in this article will offer valuable references for your practical operations.

Recommended: Glorious Laser Cutting Machines

For efficient and stable piercing and cutting of thick carbon steel up to 60mm, we highly recommend the Glorious high-power fiber laser cutting machines. With peak output power up to 30,000W, exceptional beam quality (M²<1.1), and intelligent pulse control technology, Glorious laser cutters deliver outstanding performance in thick-plate piercing—enabling fast piercing, zero blowouts, minimal heat-affected zones, and significantly improved cutting efficiency and edge quality.

Equipped with a fully closed-loop gas pressure control system, high-precision focus adjustment, and smart multi-stage piercing programs, Glorious cutting systems precisely match the process requirements of various carbon steel thicknesses. Whether processing 50mm or 60mm carbon steel, Glorious ensures consistent, reliable performance—making it the ideal choice for high-end heavy industries, shipbuilding, and construction machinery manufacturing.

Why Choose Glorious Laser Cutting Machines?

✅ Ultra-High Power, Deep Penetration: 30,000W lasers effortlessly pierce and cut 60mm thick carbon steel, expanding processing capabilities.

✅ Intelligent Pulse Control: Precise adjustment of pulse frequency and duty cycle prevents blowouts and enhances piercing stability.

✅ Fully Closed-Loop Gas System: Ensures precise and stable gas pressure for smoother cut surfaces.

✅ Industrial-Grade Protection (IP65): Built to withstand harsh environments—dust, moisture, extreme temperatures—for reliable operation.

✅ Energy Efficient, Lower Operating Costs: Up to 45% electro-optical efficiency reduces long-term energy expenses.

✅ Local Service & Technical Support: Global service network ensures fast response and continuous operational support.

Customer Testimonials: Real User Experiences

🔹 Engineer Zhang | Technical Director, Heavy Machinery Manufacturer

“Since we introduced the Glorious 30,000W laser cutter, the piercing success rate for 60mm carbon steel has increased from 70% to over 98%. Blowouts have been significantly reduced. The intelligent multi-stage piercing function is highly practical—parameters are recalled with one click, making operation simple and reducing setup time. Our thick-plate cutting efficiency has improved by 40%, and cut surface perpendicularity and smoothness far exceed our previous machines.”

🔹 Manager Li | Production Lead, Shipbuilding Fabrication Plant

“In the past, we had to constantly adjust gas pressure and focus when cutting 50mm carbon steel. Now, with Glorious’s preset process packages, manual intervention is almost unnecessary. The IP65 protection performs exceptionally well in our high-dust workshop—three months of continuous operation with zero downtime. Customer support is also excellent; a technician resolved our issue remotely within ten minutes.”

🔹 Director Wang | Procurement Head, Metal Processing Industrial Park

“Six companies in our park have trialed Glorious high-power laser systems, and all reported faster cutting speeds, stable piercing, and lower energy consumption. The pulse control is especially precise—no more ‘blow-up’ during thick-plate piercing, and nozzle and lens wear have noticeably decreased. We’ve decided to proceed with bulk procurement to replace our aging equipment.”