When customizing aluminum enclosures, the choice between laser cutting and CNC machining directly impacts product quality, production cost, and lead time. While both processes can achieve high-precision results for cutting holes or shaping profiles, their optimal applications differ significantly.

Need small-batch prototyping, complex geometries, or non-flat surfaces? CNC offers greater flexibility.

Prioritizing high-volume production, standard parts, and mold-free efficiency? Laser cutting is the superior choice.

This article compares laser cutting and CNC machining across five key aspects—precision, cost structure, productivity, material compatibility, and maintenance—to help you make an informed decision for your enclosure manufacturing needs.

In the customization process of aluminum enclosures, the selection of manufacturing techniques is crucial. When faced with aluminum enclosure samples achieving identical results, how would you choose the production method? In reality, the choice of techniques depends not only on the product itself but also on the desired final effect and the production volume.

For example, what technique should be selected to manufacture an aluminum alloy enclosure with a screen aperture? Most would opt for laser cutting. However, it’s important to note that for smaller production runs, CNC machining often offers greater advantages. The reason lies in the non-flat surface of aluminum alloy enclosures. Laser cutting requires an additional fixture mold to secure the enclosure on the laser cutting machine, ensuring the hole-cutting process proceeds smoothly. This setup significantly increases costs.

Taking this opportunity, let’s explore the differences between laser cutting and CNC machining.

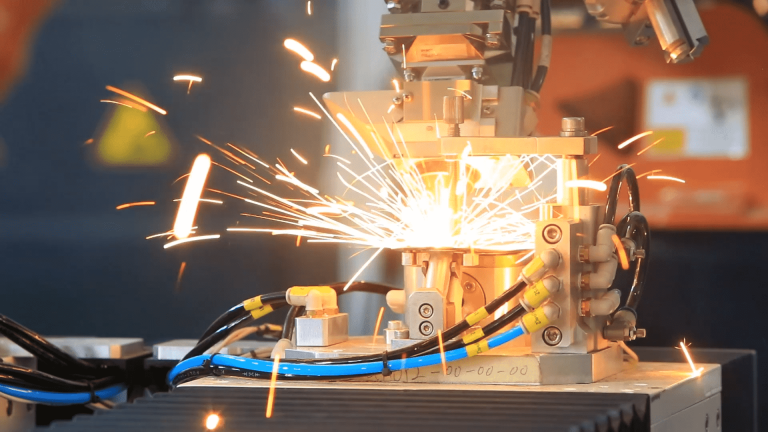

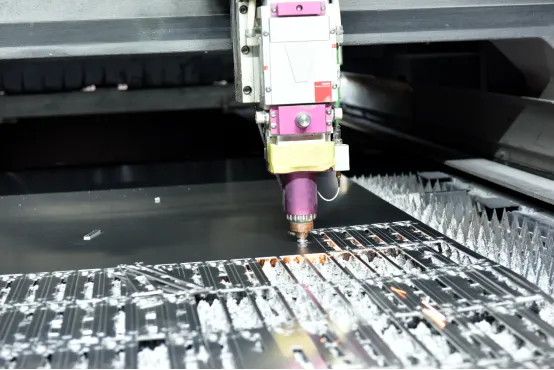

1.Laser Cutting

A high-power-density laser beam is directed at the material to be cut, rapidly heating it to vaporization temperature. This causes evaporation that forms a hole. As the beam moves across the material, the hole continuously forms a narrow slit (approximately 0.1mm wide), completing the cutting process.

Key Features

1.Superior cutting quality, reduced labor costs

Leveraging the non-contact processing characteristics of laser cutting machines, workpieces remain undamaged. Cut products exhibit no deformation from pressure, ensuring high-quality output with no burrs. Manual polishing becomes unnecessary, eliminating redundant processing steps and optimizing worker workload.

2.Saves Mold Investment, Lowers Production Costs

Laser cutters enable direct, mold-free fabrication of various metal components. Eliminating mold consumption, repairs, and replacements significantly reduces mold usage, processing expenses, and overall production costs—particularly advantageous for large-scale product manufacturing.

3.High precision, significantly boosting productivity

Emerging as an alternative to “shearing-punching,” laser cutting offers precision, flexibility, and efficiency. It effectively processes complex parts—simply prepare the cutting pattern, import it into the control system, and set dimensions for cutting. This directly shortens product processing and manufacturing cycles, substantially enhancing labor productivity.

4.Rapid cutting speed and optimized work environment

Laser cutters operate swiftly with stable equipment, minimal noise, and no dust. They produce no harmful chemicals, offering considerate protection for operators while ensuring a clean and tidy production site. This reduces follow-up investments, minimizes pollution, and helps hardware enterprises optimize their work environment while aligning with environmental protection trends.

5.Low maintenance costs, high cost-effectiveness

Maintaining mechanical equipment is costly. Laser cutting machines, however, offer stable performance, robust durability, and continuous operation with minimal breakdowns. This provides significant advantages in reducing long-term maintenance expenses.

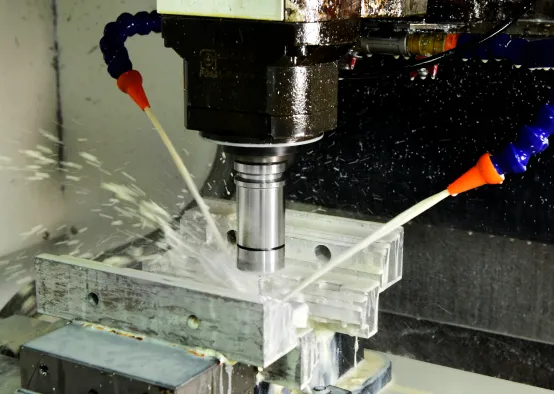

2.CNC

CNC (Computer Numerical Control) is an abbreviation for computer-numerically controlled machine tools. It refers to automated machine tools controlled by programs. This control system can logically process programs specified by control codes or other symbolic instructions. By decoding these instructions through a computer, the machine tool executes predetermined actions. Through tool cutting, it transforms raw materials into semi-finished or finished parts.

Key Features

1.Minimal Setup Error

Traditional machine tools rely on the operator’s proficiency with measuring tools. While skilled workers can achieve highly precise part setup, truly exceptional operators are rare domestically. This is why many CNC systems employ dedicated coordinate measuring probes. Typically mounted as a tool in the spindle, these probes determine part position by contacting fixed components. After establishing the coordinate system’s zero point, setup errors are minimized.

2.Consistent Repeatability

Nothing matches the stability of a validated computer program. Machine movements remain identical, as precision depends solely on stepper motor accuracy. In conventional machining, repeatability varies significantly due to operator influence. Human error invariably outweighs programming inaccuracies.

3.Reduced Trial Runs

Traditional machining inevitably requires test parts. CNC systems eliminate trial runs through visualization. They employ visualization systems allowing operators to actually see what will happen to the stock after all tools have passed through.

4.Complex Surfaces Made Easy

Manufacturing complex surfaces with high precision using traditional methods is nearly impossible. It requires significant manual labor. CAM systems can automatically generate toolpaths for any surface. This is one of the greatest advantages of modern CNC machining technology.

5.Greater Machine Flexibility

Traditionally, milling machines cut slots or planes, lathes process cylinders and tapers, and drilling machines make holes. CNC machining combines all these functions within a single machine. By programming toolpaths, you can replicate any movement on any machine. Thus, we have milling centers that produce cylindrical parts and lathes that cut slots. All this reduces part setups.

3.Laser Cutting vs. CNC Machining

1.Cutting Intensity. Refers to the strength of the laser beam striking the material surface. For a given cut, higher intensity results in greater depth. Adjustable within a range of 1% to 100%, with increments of 1%. Higher intensity corresponds to higher speed and greater cutting depth.

2.Cutting Speed. Refers to the movement speed of the laser head, typically measured in IPS (inches per second). Higher speeds yield greater production efficiency. Speed also controls cutting depth; for a given laser intensity, slower speeds result in greater cutting depth.

3.Spot Size. CNC and laser cutting actually employ different spot sizes. Laser beam spot size can be adjusted using lenses with varying focal lengths. Small-spot lenses are used for high-resolution cutting. Large-spot lenses are used for lower-resolution cutting but are the optimal choice for vector cutting. New equipment comes standard with a 2.0-inch lens. Its spot size is intermediate, suitable for a wide range of applications.

In conclusion, neither laser cutting nor CNC machining is universally superior—each excels in different scenarios.

For high-volume, flat, standardized aluminum enclosures, laser cutting is ideal due to its high speed, low cost, no tooling, and high automation.

For small batches, complex shapes, non-planar surfaces, or high-precision components, CNC machining offers unmatched flexibility and accuracy.

Many manufacturers adopt a hybrid strategy: CNC for prototyping + laser for mass production, balancing R&D agility with manufacturing efficiency.

When choosing a process, always consider part geometry, order volume, lead time, and budget to maximize cost-effectiveness.

Yonggu Manufacturing specializes in high-quality enclosure fabrication, offering expert process guidance and one-stop machining solutions to bring your product to market faster and smarter.