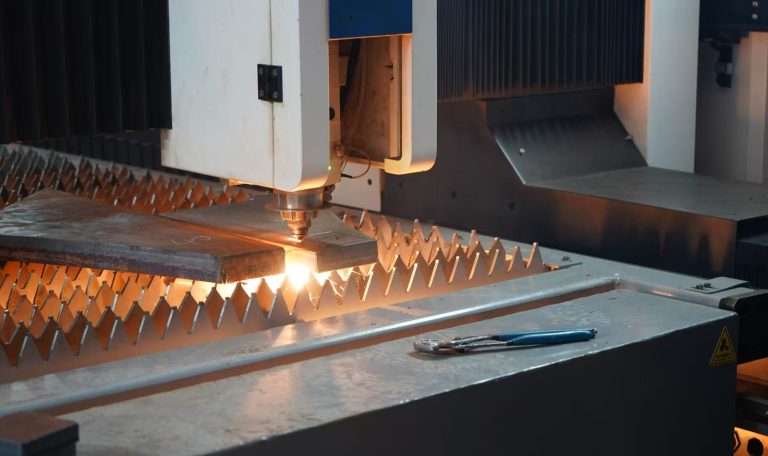

We all know that the laser cutting machine has been used for the processing of carbon steel plate, and the processing is carried out by means of heating. So in the process of processing will encounter a variety of problems, each problem has a different cause and solution. A lot of people are asking why laser cutting machine cut carbon steel always black edge? This is also the most commonly encountered problem. So laser cutting machine cutting carbon steel always black edge in the end how? How to solve it?

Laser cutting machine cutting carbon steel always black edge reasons

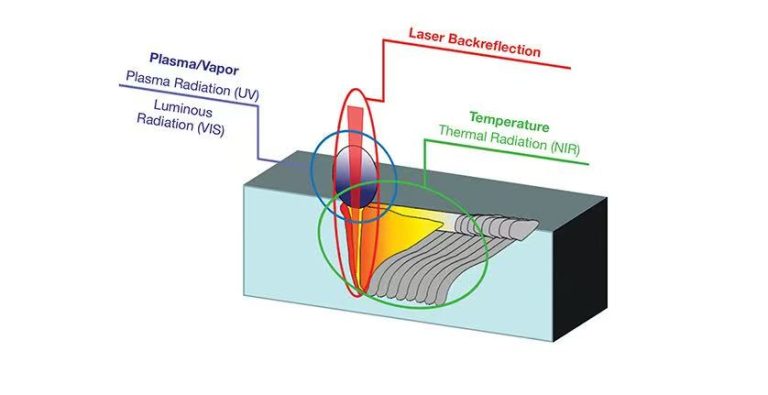

In fact, the cause of the laser cutting machine to cut carbon steel total black edge is in the cutting will release a large amount of heat, due to the thermal conductivity of the metal is relatively good, under normal circumstances, the heat generated by cutting will be spread along the cutting seam to the processed sheet metal to get fully cooled. But the metal laser cutting machine in the processing of small holes, the outside of the hole can be fully cooled, a single hole inside the small hole part of the heat can be diffused because of the space is small, the heat is too centralized, thus causing black edges, slag and so on. In addition, in the thick plate cutting, perforation produced by the accumulation of molten metal on the surface of the material and the accumulation of heat will make the auxiliary air flow disorder, excessive heat input, resulting in black edge.

Solution

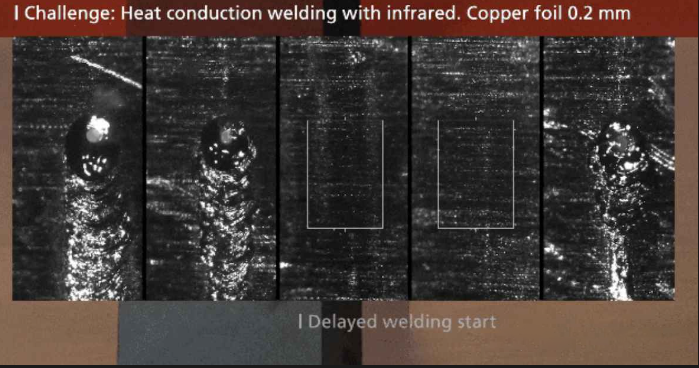

In carbon steel cutting with oxygen as auxiliary gas, the key to solving the problem lies in how to suppress the generation of oxidizing reaction heat. The method of cutting with auxiliary oxygen during piercing and switching to auxiliary air or nitrogen after lagging can be adopted. This method can process small holes up to 1/6 thick plate. Pulsed cutting conditions with low frequency and high peak output power have the characteristic of being able to reduce heat output, which contributes to the optimization of cutting conditions. Setting the conditions to a single pulsed laser beam, high peak output with high energy intensity, and low-frequency conditions effectively reduces the buildup of molten metal on the surface of the material during perforation and effectively suppresses heat output.

In this type of material processing, the auxiliary gas used is nitrogen, and edge burning will not occur in cutting, however, due to the high temperature of the material on the inside of the small hole, slag hanging on the inside will be more frequent. An effective solution is to increase the pressure of the auxiliary gas and set the conditions to high peak output and low frequency pulse conditions. Auxiliary gas with air is also the same as when using nitrogen, will not occur when the black edge, but it is easy to hang slag on the bottom, you need to set the conditions for high auxiliary gas pressure, high peak output, low-frequency pulse conditions.

Above is the laser cutting machine cut carbon steel is always black edge of the specific content and solutions, in fact, it is not difficult to see this problem although it is a common problem as long as a little attention in the processing process can be avoided, we can be based on the above method and then check the operation according to the actual situation.