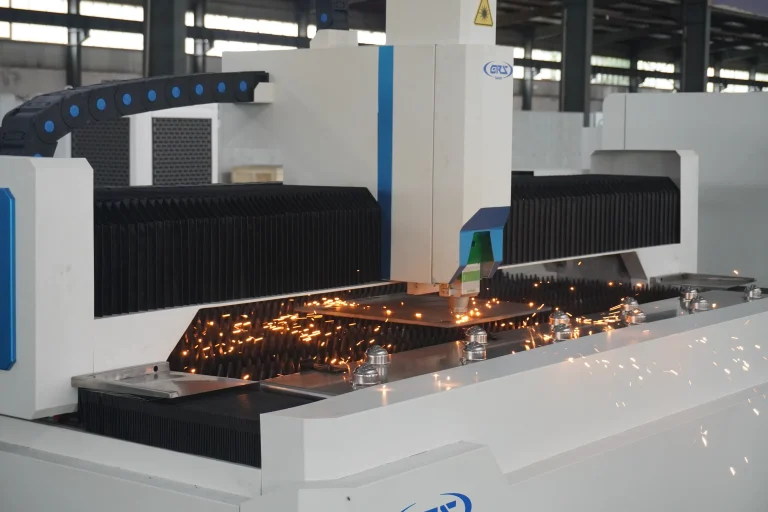

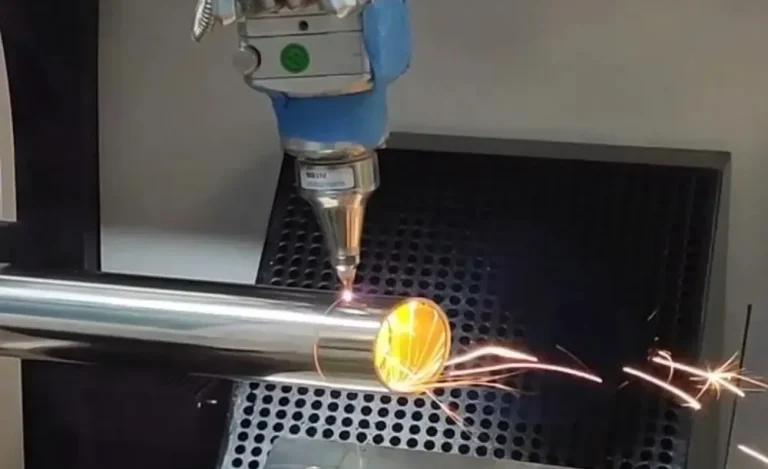

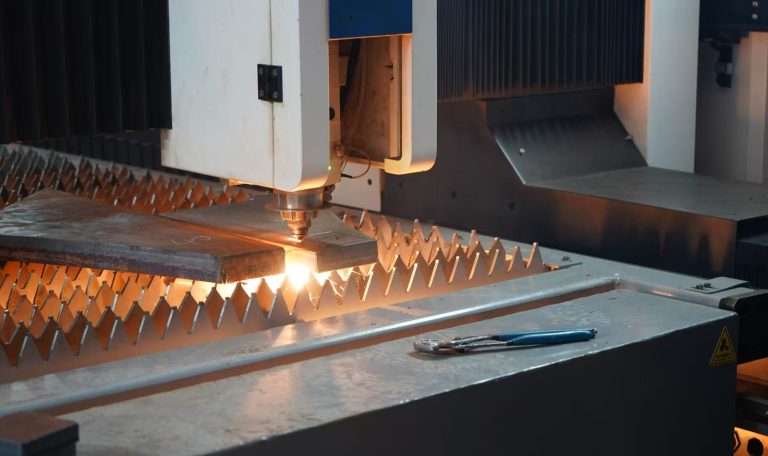

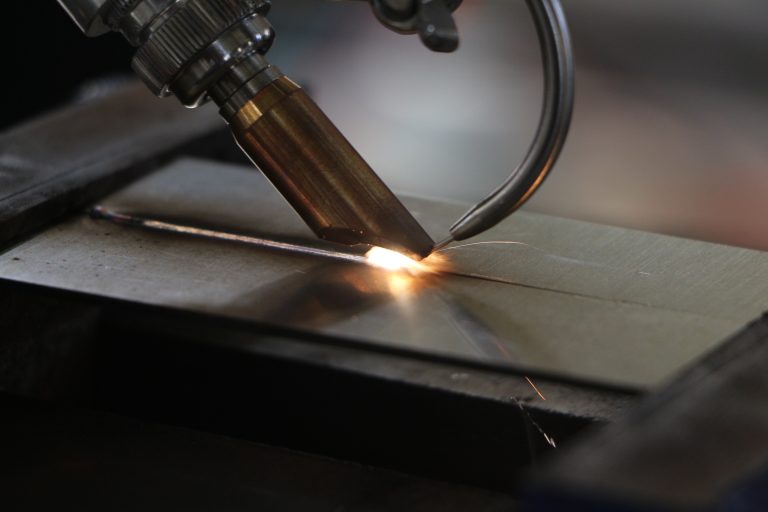

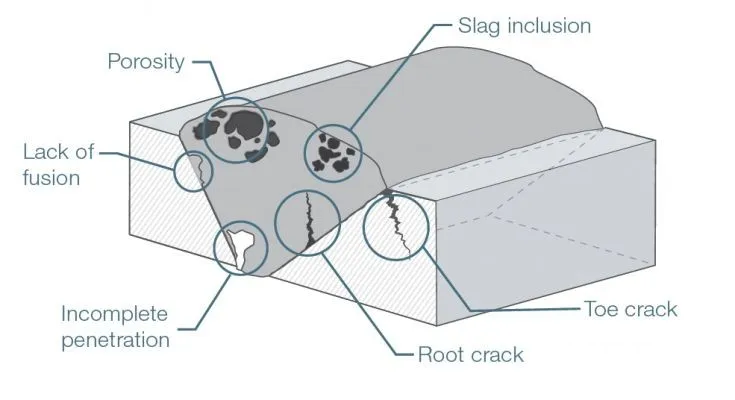

In modern industrial production, the quality inspection of laser welds is critical. To ensure the safety and reliability of welded joints, it is essential to employ advanced non-destructive testing techniques. This article introduces six common methods for laser weld inspection: Eddy Current Testing (ET), industrial microscope examination, conventional ultrasonic testing, remote visual inspection, phased array ultrasonics, and X-ray fluorescence analysis. These insights will help you better understand and select the appropriate inspection solutions.

- Eddy Current

Eddy current testing (ET) is one of the non-destructive testing methods used in industry.

Fast and effective detection of surface and subsurface cracks

- High detection rates without removing paint

- Wide coverage and fast scanning saves time

- Replaces penetrant and magnetic particle inspection

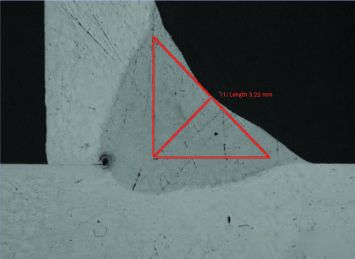

- Industrial Microscope

Check the cross-section of the weld with our imaging solutions

- All measurements in one step for fast inspection

- Suitable for T-joints, lap and fillet joints and all weld sizes

- Calibrate imaging for reliable results

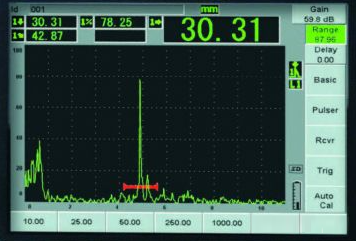

- Conventional ultrasound

High quality defect detection, very easy to use

- Rugged, ergonomic design enables use in challenging environments

- Intuitive interface useful for both experienced and novice inspectors

- Full range of UT probes for detecting and measuring weld defects

- Remote Visual Inspection

Inspection of hard-to-reach areas

- Optimal image quality for clear visualization

- Increased probability of detection with vibrant colors and clear images

- Efficient assessment of weld damage

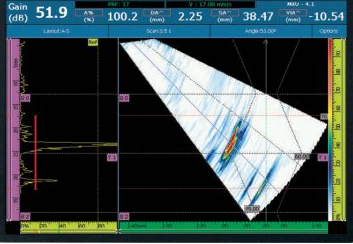

- Phased Array Ultrasound

Accelerates your examination process

- High-speed detection capability helps to explain

- Reduced examination time compared to radiography

- Instant results allow you to detect and fix process problems immediately

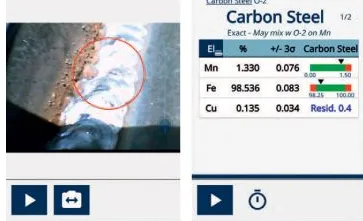

6. X-ray fluorescence

On-site weld inspection and reliable material characterization

- Alloy verification helps to ensure that the correct welding material is used

- Avoids corrosion, cracks and damage

- Analyzes in seconds with no impact on welds

In conclusion, there are various methods available for laser weld inspection, each with its unique advantages and suitable applications. From the fast and efficient Eddy Current Testing to the precise X-ray Fluorescence Analysis, these tools and techniques collectively form a comprehensive quality assurance system. By appropriately selecting these inspection methods, not only can product quality be enhanced, but potential safety hazards can also be effectively prevented. We hope this article provides valuable insights for your quality control efforts.