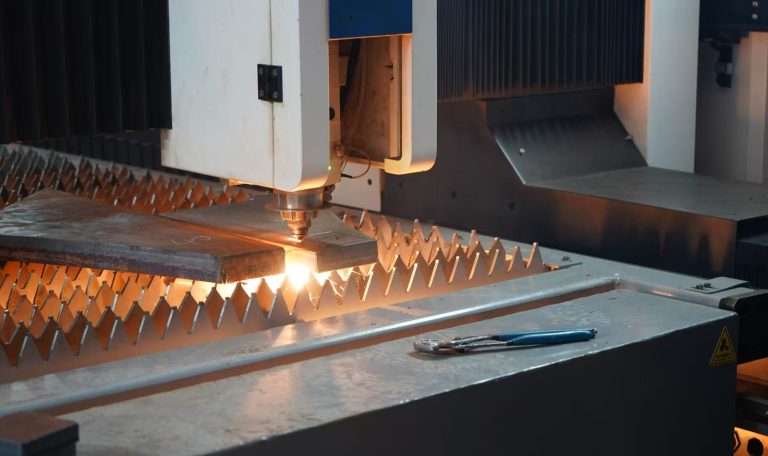

Ultimate Guide to Perfect Piercing of 60mm Carbon Steel with 10kW Lasers

Laser cutting down requires two steps to realize – piercing and cutting. Only by ensuring good and stable perforation results…

Contacts : David Wang | Email: cnlaser2011@gmail.com | WhatsApp: +86 15253660692

Request a Quote For laser machine – Glorious Laser

Laser cutting down requires two steps to realize – piercing and cutting. Only by ensuring good and stable perforation results…

With the advancement of industrial technology, 10kW fiber lasers play a crucial role in high-speed, high-quality cutting of thick carbon…

When the laser cutting machine is cutting carbon steel material, due to the hardness of carbon steel, in order to…

In the ever-evolving landscape of industrial manufacturing, achieving high efficiency and precision in cutting carbon steel has become a critical…

We all know that the laser cutting machine has been used for the processing of carbon steel plate, and the…

Laser cutting is widely used in carbon steel processing due to its high precision and efficiency. However, common issues such…

With the development of technology, there are more and more cutting methods, such as: laser cutting, water cutting, plasma cutting,…

With the development of automobile to the direction of low carbonization, diversification, intelligence, automobile lightweight has been the general trend….

Shipbuilding industry has been known as “the crown of the comprehensive industry” title, its huge amount of steel and complex…