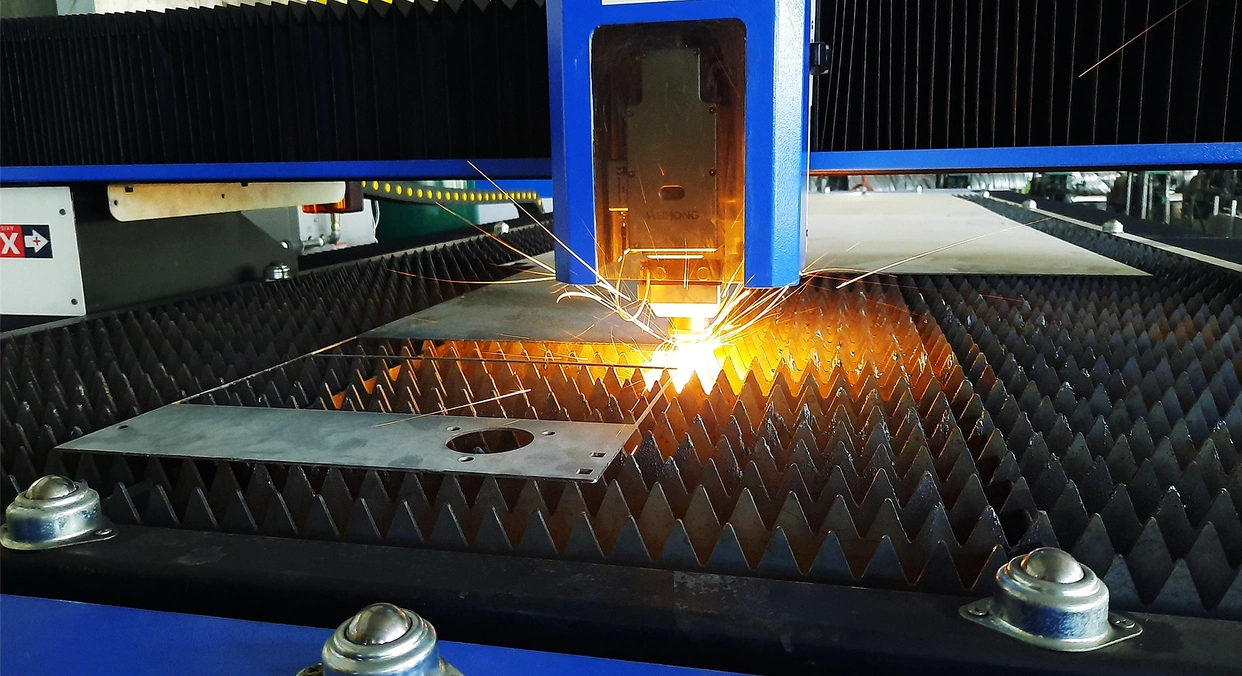

As the world’s scientific and technological progress, industrial empowerment has led to a number of smarter, more advanced instruments updated, such as the sheet metal processing industry to be used in the laser cutting machine. The high energy density of the laser beam irradiated to the workpiece to be processed, so that its local heat melting, and then use high-pressure gas to blow away the slag line into a slit, laser cutting machine is more and more enterprises to accept.

So what are the advantages of utilizing a laser cutting machine to process sheet metal workpieces? May as well come together to understand it!

- Good processing quality, narrow slit, smooth and clean appearance after cutting, without the need for subsequent processes in the processing, more savings in manpower and labor.

- Laser fully automatic or semi-automatic, can be closed processing, no pollution, noise impact is small, reducing the hazards brought to the operator.

- Reduced processing costs, laser cutting machine automatic layout can not be limited to the cutting pattern, can be faster and better continuous cutting, saving time and improving efficiency.

- laser cutting process as an alternative process to shear flushing, with accurate, flexible, efficient features, can effectively process a variety of complex parts, as long as the cutting graphics, access to the control system, you can set the cutting size, help directly shorten the product processing and manufacturing cycle, effectively improve labor productivity.

- The high energy of the laser beam is enough to melt most of the metals, which is especially suitable for some metals with high hardness, high brittleness and high melting point, which is more comprehensive and convenient than the general machining process.

- Low post maintenance cost, cost-effective. Maintenance of mechanical products is very expensive, laser cutting machine performance is stable, durable, can work continuously, not easy to damage, in the late maintenance cost has a great advantage.

- The laser processing system is a complete set of computer systems, can be scheduled according to the needs of the program, modify the program, especially suitable for some complex structure of the mold and some mass production of components.

- The traditional cutting process exists to replace the mold process, while the laser cutting machine does not have this need, the laser cutting machine only need to change the program can be, saving a lot of time, allowing a smaller production run to drive a large number of operations processing.

These are the advantages of the laser cutting machine as a mode of sheet metal processing, nowadays, with the extensive use of machining and laser cutting technology, the development of laser cutting machine further accelerated. The development of laser cutting machine can make the technology more advanced in the application process. From the current development, the laser cutting machine will also be developed in the direction of intelligence, to bring greater help to enterprises.