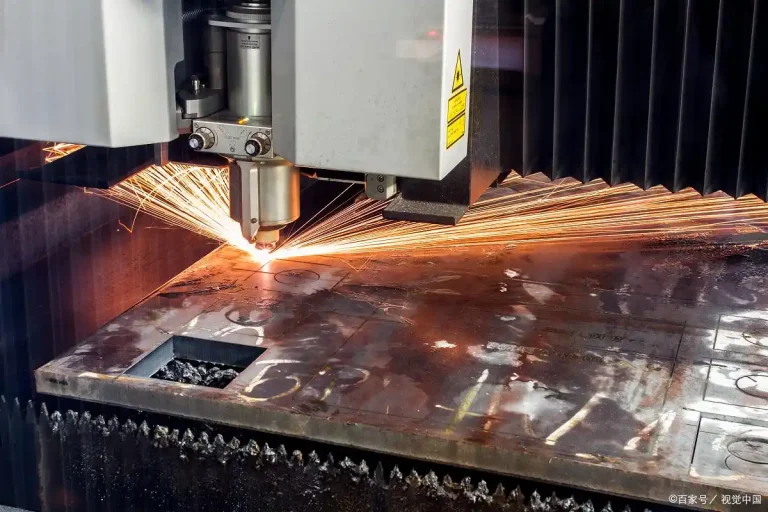

In the field of metal processing, bevel cutting is an indispensable pre-welding process. Traditional cutting methods such as flame cutting, plasma cutting, or mechanical milling have long dominated the industry. However, as manufacturing demands increasingly stringent requirements for efficiency, precision, and cost, laser bevel cutting technology has gradually emerged as a focal point. This article will analyze the core advantages of Glorious laser bevel cutting through technical comparisons and user case studies.

Technical Bottlenecks in Traditional Thermal Cutting Processes

In the metal sheet processing industry, machining ultra-thick and highly reflective metal sheets has long been constrained by technological limitations. Taking materials such as stainless steel, carbon steel, and aluminum alloys as examples, multiple issues arise when employing plasma or flame cutting processes, hindering both production quality and efficiency.

In terms of cut surface quality, traditional cutting methods exhibit significant fluctuations in surface roughness, making them unsuitable for high-precision welding requirements. During the cutting process, high heat input expands the heat-affected zone, altering material microstructure and properties, which in turn impacts subsequent processing. When balancing cutting speed and precision, traditional methods often sacrifice one for the other: prioritizing speed compromises cutting accuracy and leads to large bevel angle deviations; focusing on precision drastically reduces cutting efficiency, failing to meet mass production demands. Furthermore, traditional processes face inherent limitations when cutting ultra-thick plates. For materials exceeding 20mm in thickness, cutting stability and quality control become exponentially more challenging, forming a persistent technical barrier that has long eluded industry breakthroughs.

Core Breakthroughs in Laser Cutting Technology

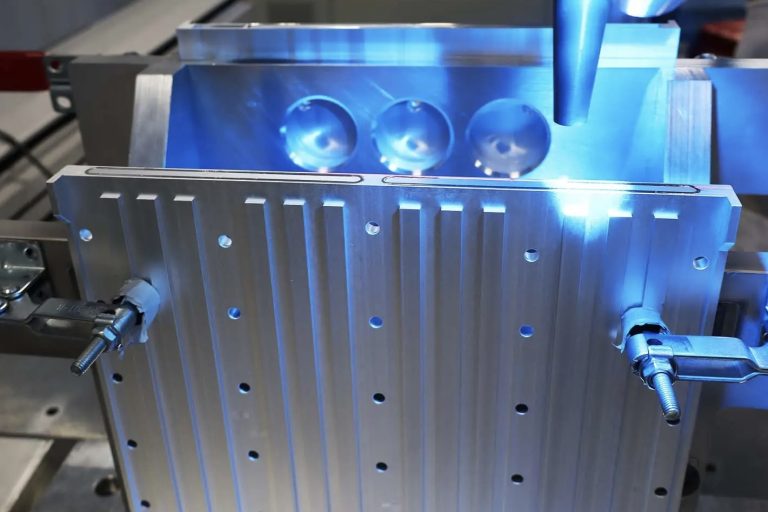

In the field of laser cutting, traditional thermal cutting techniques have long faced technical challenges when processing materials like stainless steel, carbon steel, and aluminum alloys. These include unstable cut quality, difficulty balancing precision and efficiency, challenges in processing ultra-thick plates, complex workflows, and high costs. Liang Faji has successfully overcome these obstacles by optimizing laser cutting machines and integrating high-power lasers. During the cutting process, the optimized laser precisely interacts with the material surface, meticulously sculpting every detail like a master craftsman.

In cut edge processing, Glorious Laser breaks through the limitations of traditional techniques. Its advanced beam control technology endows the laser with a pair of flexible “hands,” enabling it to shape the cut edge with precision and freedom. Whether handling complex geometries or minute components, it performs with ease. This precision shaping significantly enhances cutting accuracy, resulting in exceptionally smooth edges. This not only provides an ideal mating surface for subsequent welding, ensuring stronger bonds, but also simplifies assembly processes, substantially improving overall production efficiency and quality.

Unleashing the Multi-Faceted Advantages of Bevel Cutting

Comprehensive Coverage of Bevel Types, Streamlined Processes for Enhanced Efficiency

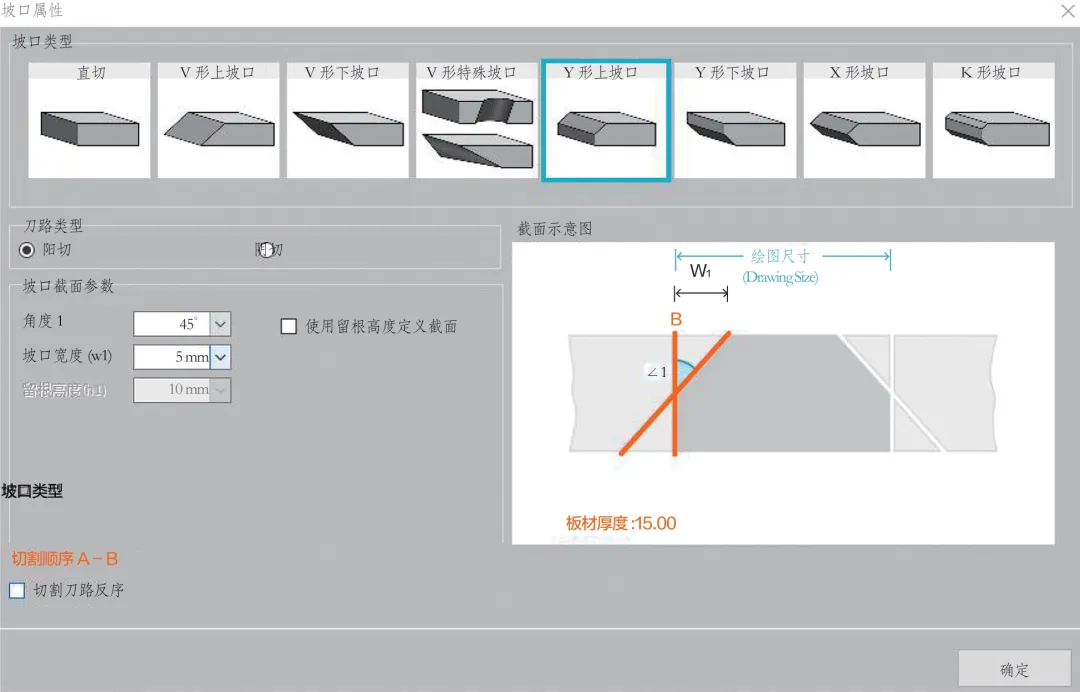

In the field of bevel cutting, traditional processing methods often face numerous challenges. For instance, handling complex bevels like V-shaped, Y-shaped, or X-shaped requires multiple machines working in tandem and involves multiple steps such as milling and grinding. This process demands frequent clamping and positioning, which is not only time-consuming and labor-intensive but also prone to cumulative errors between steps, ultimately affecting the consistency of bevel dimensions.

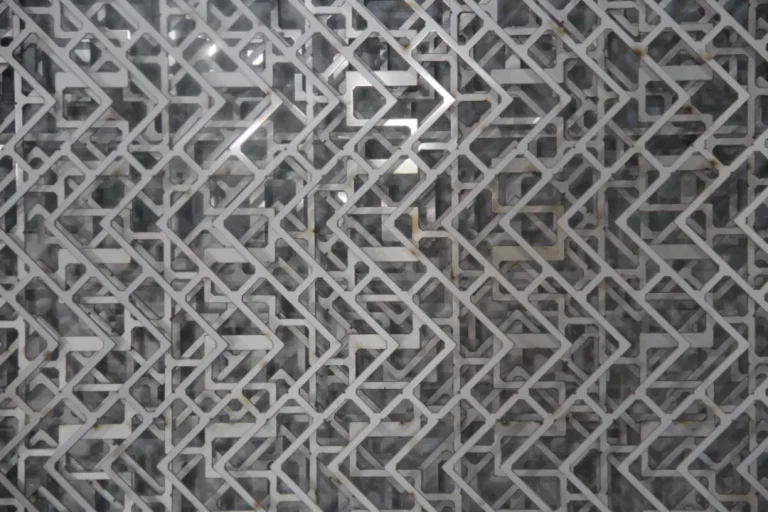

Modern laser cutting technology offers a revolutionary solution, accomplishing intricate bevel shapes in a single pass. Bevel laser cutting machines can be programmed for multiple cutting angles, effortlessly handling 0° to 45° bevel cuts as well as V-shaped, Y-shaped, X-shaped, K-shaped, and tapered bevels. This approach streamlines production processes while reducing welding complexity. During processing, the elimination of repeated clamping significantly streamlines production workflows. This effectively prevents errors caused by multiple setups, ensuring high consistency in bevel dimensions. This efficient and precise cutting method not only boosts production efficiency but also better accommodates diverse production demands. Whether for large-scale batch production or small-batch custom processing, it demonstrates formidable advantages.

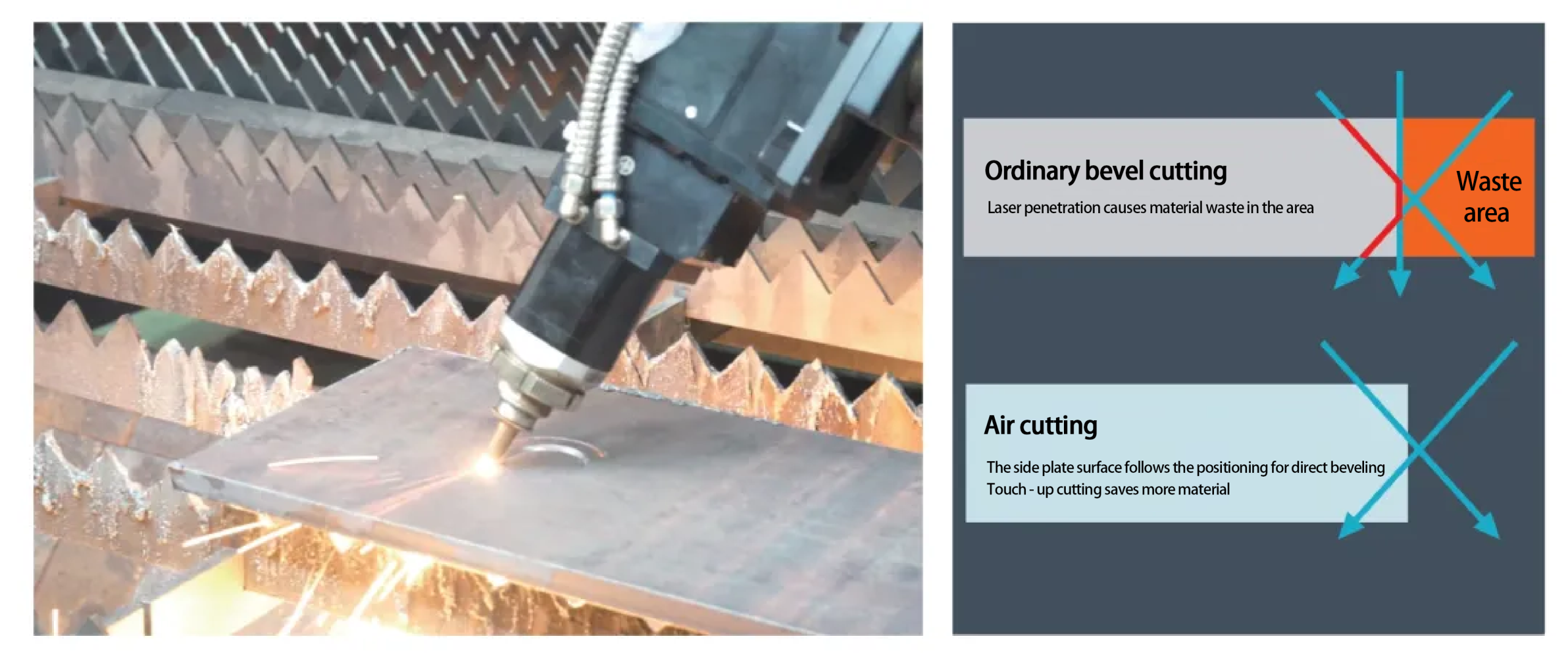

Ultimate Material Savings, Airborne Cutting

In plate processing, material savings are paramount for K-shaped bevel cutting. Traditional cutting methods result in significant waste, substantially increasing costs. Advanced cutting technology precisely plans paths, leveraging intelligent algorithms and optimized processes to efficiently utilize plates and minimize scrap. This approach reduces raw material costs, decreases waste disposal, enhances resource utilization, and helps enterprises balance processing quality while achieving both economic and environmental benefits. The aerial cutting schematic is illustrated in Figure 3.

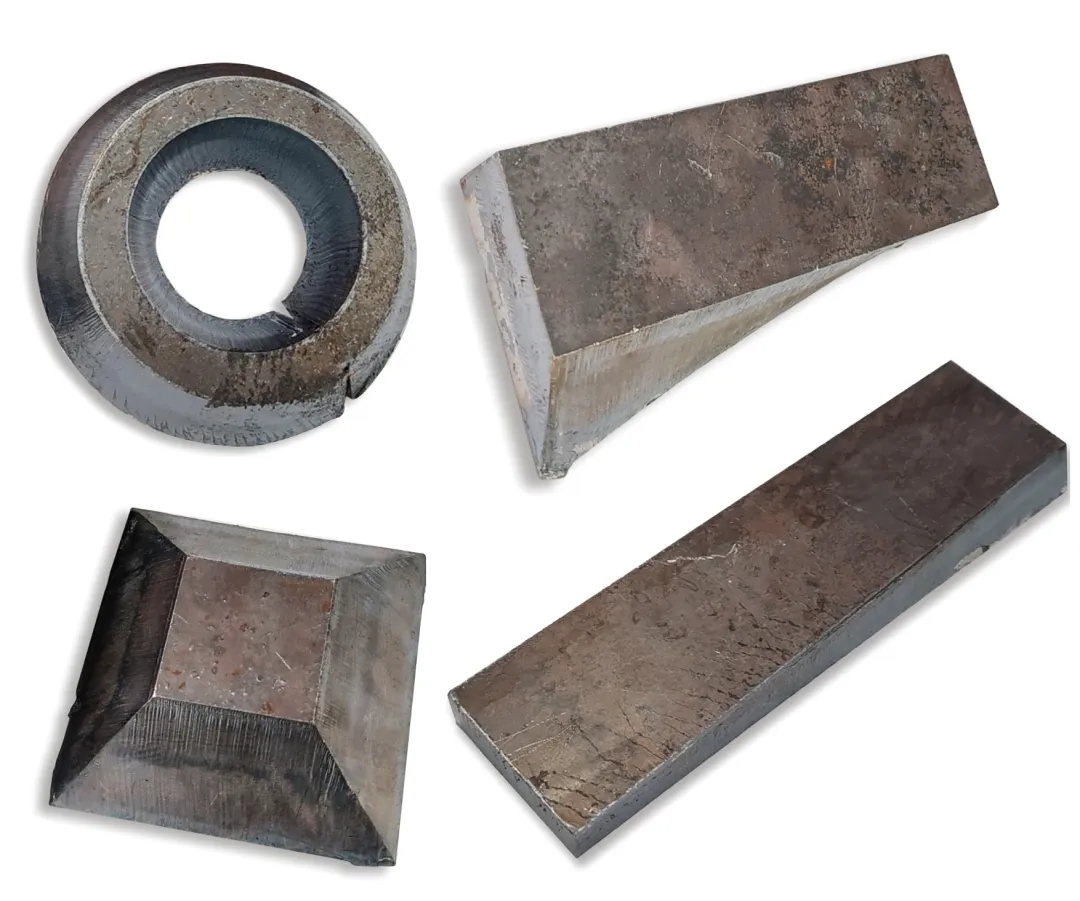

Enhanced Welding Precision and Quality, Building a Stronger Foundation

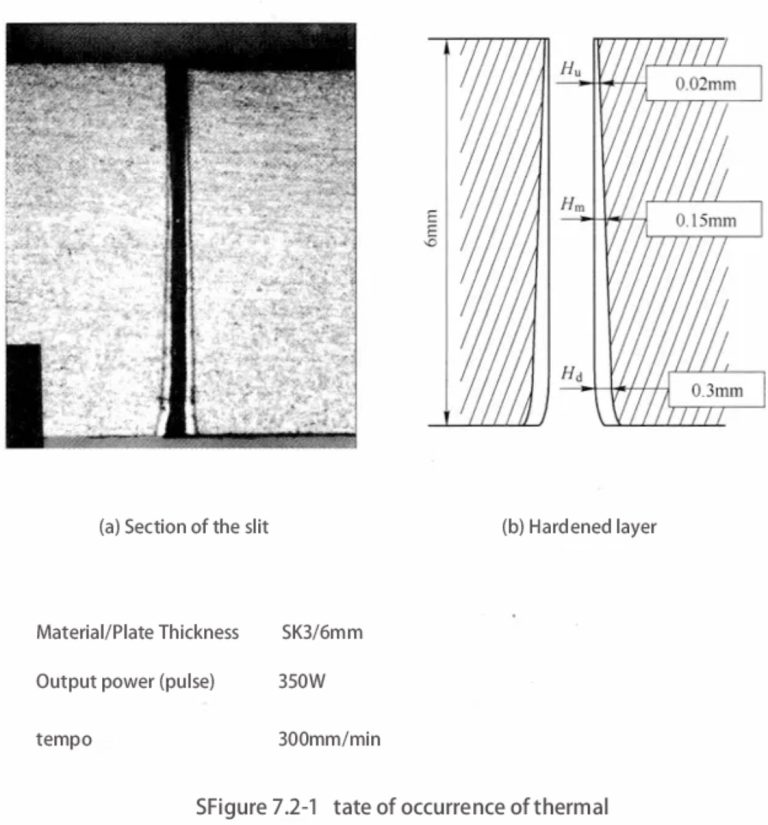

By precisely controlling the laser beam’s energy distribution and cutting angle, cutting precision is significantly improved. Bevel angle deviation is minimized, resulting in low surface roughness and smooth, stable cuts, as shown in Figure 4. This high-quality bevel cutting lays a solid foundation for welding processes: it ensures more uniform weld fusion, reduces defects such as porosity and slag inclusion, and enhances weld strength and overall structural reliability. It is particularly suitable for fields with extremely high welding quality requirements, such as construction machinery and shipbuilding.

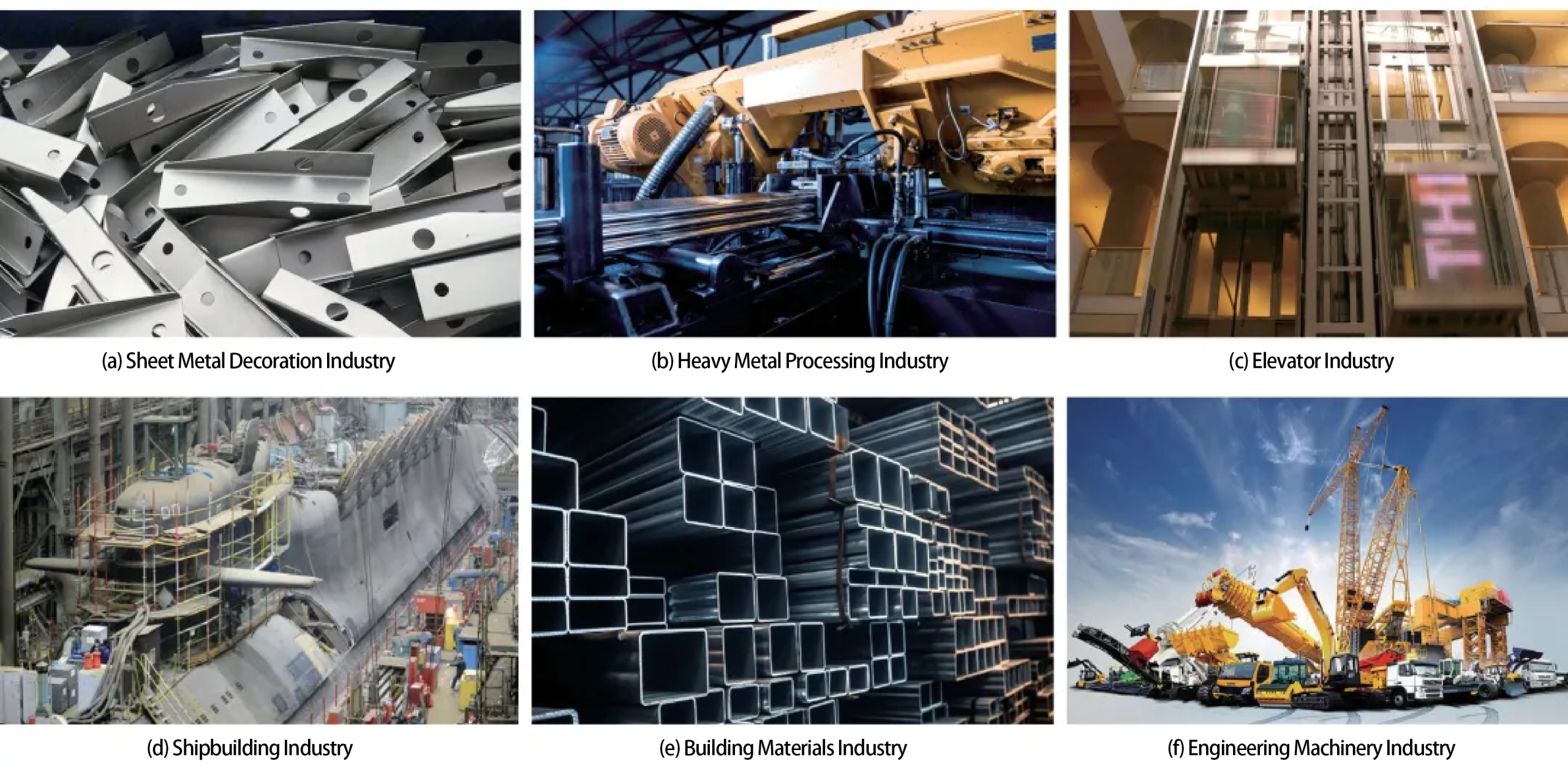

Application Areas

The primary application areas of laser bevel cutting technology are illustrated in Figure 5. It is not only suitable for high-end sectors with stringent welding quality requirements but also meets diverse needs ranging from large-scale industrial production to precision micro-machining. Its intelligent and flexible characteristics position it as a core tool for manufacturing upgrades, empowering enterprises to achieve competitive advancement through “high precision + low cost + rapid response.”

Conclusion

Laser bevel cutting technology, with its high precision, efficiency, and flexibility, is reshaping the value chain of the metal processing industry. It not only upgrades manufacturing processes but also drives end-to-end optimization from design to production. For modern enterprises pursuing quality and efficiency, laser bevel cutting is no longer merely a technological choice—it represents a strategic investment in achieving smart manufacturing transformation.

Furthermore, the continuous advancement in automation and intelligence of laser bevel cutting technology further enhances its competitiveness within the metal processing sector. Automated cutting systems enable 24/7 uninterrupted operation, reducing manual intervention and boosting production efficiency. Simultaneously, intelligent monitoring systems track the cutting process in real time, making immediate adjustments upon detecting anomalies to ensure stable and reliable cutting quality. This highly intelligent production approach not only lowers labor costs but also enhances production safety, injecting new momentum into the sustainable development of the metal processing industry.