Laser welding is mainly used for welding metallic materials, where the heat generated by the laser beam irradiation melts the material to be welded, forming a molten pool, which is subsequently cooled and solidified to form a connection. Laser soldering uses the laser’s high-energy density beam as a heat source, so that solder paste or tin wire and other solder quickly melted, so as to realize the connection between electronic components and printed circuit boards (PCBs) and so on. The two names are similar, but the working principle and application is actually different.

1.Definitions and Principles

1.1 Definition of laser welding and laser soldering

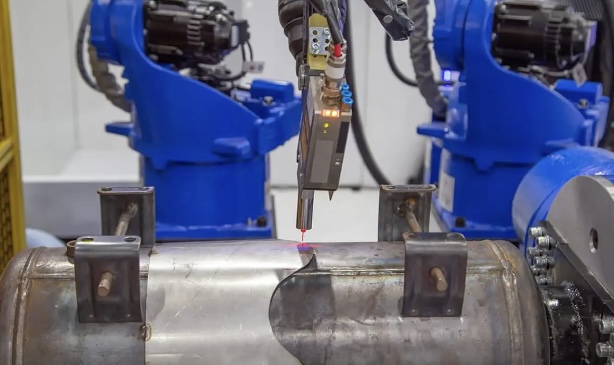

Laser welding is a processing technology that utilizes a high-energy-density laser beam as a heat source to heat the jointed parts of the materials to be welded to a molten state, thereby realizing the connection. This technology enables non-contact precision welding and is suitable for joining various metals and certain non-metallic materials. During laser welding, the laser beam precisely controls the heat input through a focusing system, which minimizes the thermal impact on the weld area, thereby reducing weld distortion and improving weld quality.

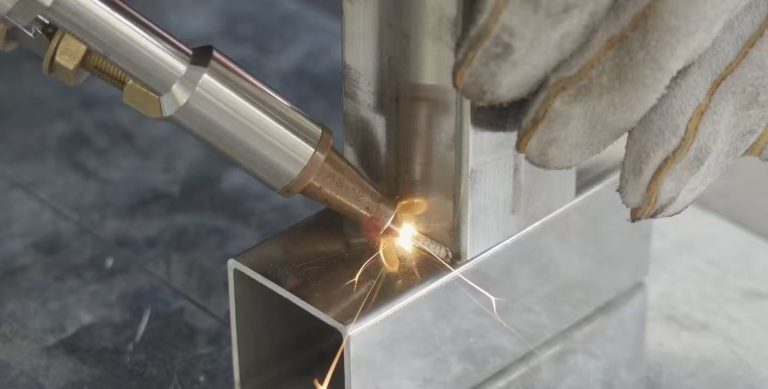

Laser soldering is a soldering technology that uses laser as a heat source and is mainly used in the electronics industry for tiny soldering operations, such as PCB boards, electronic connectors, and thermal components. Laser soldering connects electronic components to the substrate by heating the solder (usually solder paste or tin wire) with a laser beam, causing it to melt and fill the solder gap. This technology is widely used in the field of electronics manufacturing for its precise control, non-contact heating and suitability for tiny area soldering.

1.2 Principle differences between laser welding and laser soldering

Although both laser welding and laser soldering use a laser as a heat source, they differ significantly in principle and application. Laser welding focuses on the joining of metal materials, melting and joining materials through the high energy of the laser beam, and is suitable for thicker materials and structural welding. In contrast, laser soldering focuses on tiny soldering operations in the electronics industry, where the joining of electronic components is achieved by heating the solder with a laser, and is suitable for thin and light materials and precision components.

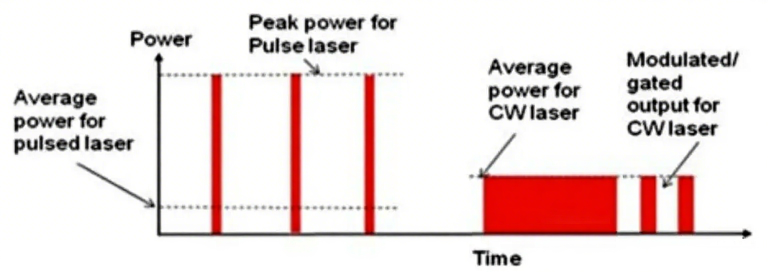

The principle of laser welding lies in the rapid melting of the material surface by the high energy input of the laser beam, the formation of a molten pool and the continuous connection of the welded area by the movement of the laser beam. Laser soldering, on the other hand, is based on the principle of using a laser beam to heat the solder, causing it to melt and fill the solder gap, forming an electrical and mechanical connection. While laser welding usually requires high laser power and energy density, laser soldering focuses more on precise control of the laser beam and thermal management to avoid thermal damage to sensitive components.

In practice, the choice between laser welding and laser soldering depends on the nature of the material to be welded, the size and shape of the part to be joined, and the required weld quality. Laser welding is important in industrial manufacturing because of its ability to achieve high-strength structural joints, while laser soldering is favored for its precision welding capabilities in the electronics industry.

2.Technical features

2.1 Details of laser welding technology

Laser welding technology plays an important role in modern manufacturing due to its high precision, speed and flexibility. The following are some of the key technical details of laser welding technology:

Energy density and heat input control: laser welding can provide up to 106106 to 108108W/cm² of energy density, this high energy density allows the material to melt quickly in a very short time, thus reducing the heat-affected area and reducing welding deformation.

Welding Speed and Depth of Melt: The speed and depth of melt of laser welding can be controlled by adjusting the laser power and welding speed. For example, increasing the laser power increases the depth of penetration, while increasing the welding speed decreases the depth of penetration. This flexibility makes laser welding suitable for a wide range of materials from thin to thick plates.

Beam Quality and Focusing: Laser welding uses a laser beam with good beam quality that can be accurately focused to a point or line as small as a micron, which is critical for precision welding. The focused beam enables welding results with depth-to-width ratios as high as 5:1 to 10:1.

Non-Contact Welding: Laser welding is a non-contact welding process, which means the weld head does not need to be in contact with the workpiece, reducing the risk of tool wear and contamination, and avoiding the need to apply additional pressure to the workpiece.

Automation and Integration: Laser welding is easily integrated with automation systems to support automated welding operations with high precision, which is especially important in mass production and the welding of complex structures.

Material Adaptability: Laser welding can be used to weld a wide range of materials including, but not limited to, stainless steel, aluminum, copper, titanium and its alloys, as well as certain plastics. This wide range of material adaptability has led to the use of laser welding in a number of industries.

2.2 Laser Soldering Technology Details

Laser soldering technology is favored for its precision soldering capabilities in the electronics industry. The following are some of the key technical details of laser soldering technology:

Micron-level Positioning and Soldering: Laser soldering enables precise positioning at the micron level, which is critical for soldering miniaturized and high-density electronic components. For example, in the soldering of PCB boards, the laser can precisely melt solder paste to fill in between microscopic pads.

Minimized heat-affected area: Due to the localized heating method of laser soldering, the heat is concentrated only in the area of the solder joint, minimizing the effect on the surrounding heat-sensitive components. This feature is particularly suitable for the manufacture of complex multilayer circuit boards.

Non-contact soldering: Laser soldering does not require the soldering head to contact the solder joint, avoiding damage to PCBA components due to contact pressure or vibration, especially suitable for brittle components and high-precision components.

High efficiency and automation: laser soldering is easy to integrate with automation equipment to support batch production and rapid welding operations of complex solder joints, significantly improving production efficiency.

Environmental protection and pollution-free: laser soldering in the welding process without smoke, no exhaust gas generation, in line with environmental requirements, to meet the demand for dust-free production environment.

Solder control: Laser soldering technology allows precise control of the amount and distribution of solder, which is critical to ensuring the quality and consistency of the solder joint. By adjusting the laser power and exposure time, the melting and flow of the solder can be precisely controlled.

Adaptability and Flexibility: Laser soldering technology can be adapted to different soldering materials and environments, including pads of different sizes and shapes, as well as different solder types such as paste, wire and balls. This flexibility allows laser soldering technology to have a wide range of applications in electronics manufacturing.

3.Application Areas

3.1 Laser Welding Application Areas

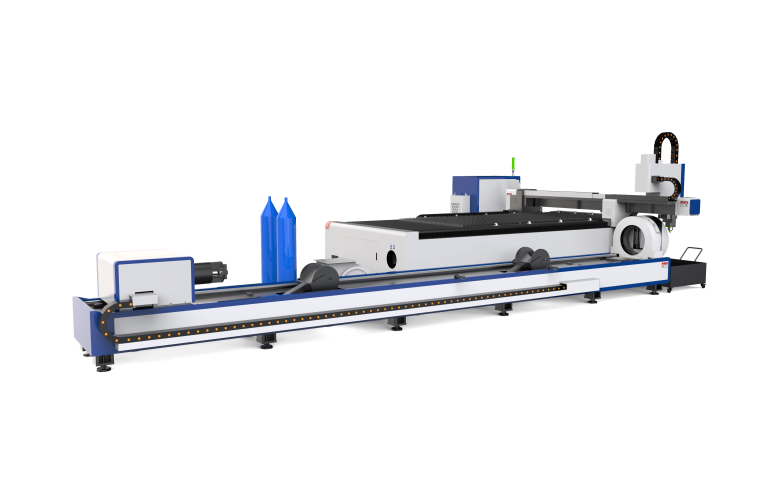

Laser welding technology is widely used in several industries due to its high precision, speed and flexibility. The following are some of the main application areas of laser welding technology:

Automotive industry: laser welding is widely used in the automotive industry, especially in body manufacturing. According to statistics, more than 80% of the world’s automobile manufacturers use laser welding technology for the welding of body structures to improve the rigidity and lightweight of the body. In addition, laser welding is also used in the production of engine components, exhaust systems and airbag systems.

Aerospace: In the aerospace sector, laser welding is valued for its ability to provide high-strength connections. Laser welding technology is used in the fabrication of aircraft fuselages, wing structures, and spacecraft components to ensure structural integrity and lightweighting.1616 The use of laser welding technology has been reported to reduce aircraft weight by up to 20%, while saving costs.

Medical Devices: Laser welding plays an important role in the manufacture of medical devices, especially in the welding of precision components made of stainless steel and titanium alloys. Laser welding can realize non-pollution, high-precision welding, to meet the strict requirements of medical devices on cleanliness and accuracy.

Electronics industry: laser welding in the electronics industry is mainly used for integrated circuits, semiconductor devices and optoelectronic devices packaging. Due to the small heat-affected area of laser welding, it can reduce the thermal damage to sensitive electronic components, so it is widely used in high-density electronic assembly.

Precision Instruments: In the field of precision instrument manufacturing, laser welding is used in the manufacture of watches, jewelry and other luxury products because of its ability to achieve high precision and quality welding. Laser welding technology ensures the delicate appearance and long-term stability of these products.

3.2 Laser Soldering Applications

Laser soldering technology is widely used in the electronics industry for its advantages in tiny soldering operations. The following are some of the main application areas of laser soldering technology:

PCB board welding: laser soldering is used in the manufacture of PCB boards for welding tiny electronic components such as chips, resistors and capacitors. Laser soldering can achieve precise solder joint positioning and solder control, improve soldering quality and production efficiency.

Electronic Connectors: In the manufacture of electronic connectors, laser soldering technology is used to solder fine conductive paths and contacts to ensure the reliability and durability of the connector.

Thermal Sensitive Components: Laser soldering is used to solder temperature sensitive components such as sensors and thermocouples due to its precise thermal control, avoiding the thermal damage that can be caused by traditional soldering methods.

Microelectronics: In microelectronics, laser soldering technology is used to solder miniature circuits and Flexible Printed Circuits (FPCs), applications that require extreme soldering precision and tight control of thermal effects.

Consumer Electronics: Laser soldering technology is used to solder miniature cameras, displays and other critical components in the manufacture of smartphones, tablets and other portable electronic devices.

LED Lighting: In the LED lighting industry, laser soldering technology is used to solder LED chips and substrates to improve luminous efficacy and heat dissipation performance, and to extend the life of LED products.

4.Comparison of advantages and disadvantages

4.1 Advantages and disadvantages of laser soldering

Advantages:

Micron-level positioning and soldering: laser soldering can achieve precise positioning at the micron level and is suitable for soldering high-density electronic components.

Minimization of heat-affected areas: laser soldering using localized heating mode, the surrounding heat-sensitive components to minimize the impact, suitable for multi-layer circuit board manufacturing.

Non-contact soldering: Laser soldering does not require the soldering head to contact the solder joint, avoiding damage to PCBA components, especially suitable for brittle components and high precision components.

High efficiency and automation: laser soldering is easy to integrate with automation equipment, supporting batch production and rapid soldering operations of complex solder joints, improving production efficiency.

Environmentally friendly and non-polluting: Laser soldering produces no fumes or exhaust gas during the soldering process, which meets environmental requirements and satisfies the need for a dust-free production environment.

Precise solder control: laser soldering technology can accurately control the amount and distribution of solder to ensure the quality and consistency of solder joints.

Disadvantages:

Restricted range of applications: Laser soldering is mainly suitable for tiny soldering operations in the electronics industry, with limited applications for large-size or structural soldering.

Equipment cost and maintenance: Although laser soldering equipment is usually less expensive than laser welding equipment, it still requires some investment and maintenance costs.

High requirements for the operating environment: laser soldering has strict requirements for the storage and use of the ambient temperature, the welding process is prone to blowing tin, spatter and other problems.

5.Market and Trends

5.1 Laser Solder Market Applications and Trends

The application areas of the laser solder market are focused on the electronics industry, especially microelectronics and precision soldering. The following are the main application areas and future trends of the laser solder market:

Continued demand from the electronics industry: with the rapid development of consumer electronics, automotive electronics and communication electronics, the application of laser solder in the electronics industry will continue to grow. Especially in the manufacturing of products such as smartphones, tablet PCs and wearable devices, laser soldering technology provides high-precision and high-efficiency soldering solutions.

Precision soldering of PCBs and FPCs: Laser soldering plays an important role in the soldering of PCBs and flexible circuit boards (FPCs). With the development of electronic devices towards thinness and miniaturization, the demand for laser soldering technology will further increase.

Growth in the LED lighting industry: In the LED lighting industry, laser soldering technology is used to solder LED chips and substrates to improve luminous efficacy and heat dissipation performance, and extend the service life of LED products. As the LED lighting market continues to expand, the market demand for laser soldering will also grow.

Technological advancements and automation trends: Automation and intelligence trends in laser soldering technology will drive the market. Laser soldering equipment that integrates advanced software and automation features will improve the control, monitoring and traceability of the soldering process, enhancing production efficiency and product quality.

Environmental protection and health and safety requirements: laser soldering as a non-polluting, fume-free welding technology, in line with the modern manufacturing industry on environmental protection and health and safety requirements. With the global emphasis on environmental protection and occupational health and safety, the application of laser soldering technology will be further expanded.

6.Summary

After comparing the differences and applications of laser soldering and laser welding, we can draw the following conclusions:

Laser welding and laser soldering each have their own unique advantages and application areas. Laser welding occupies an important position in industrial manufacturing with its high-strength joining capability and wide range of material adaptability. Laser soldering, on the other hand, plays a key role in the electronics industry with its micron-level precision welding and its ability to protect heat-sensitive components. With the continuous development of technology and increased market demand, both technologies will continue to play an important role in their respective fields and promote technological progress and industrial upgrading in related industries.