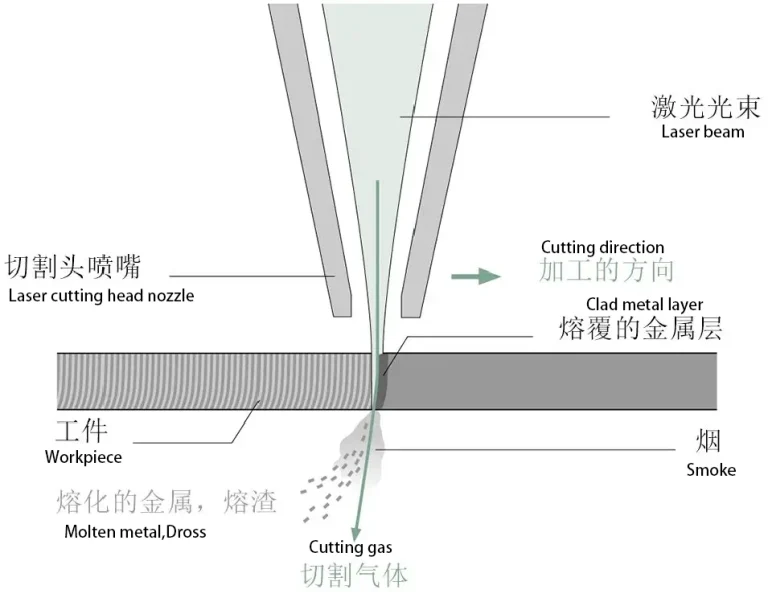

With the advancement of industrial technology, 10kW fiber lasers play a crucial role in high-speed, high-quality cutting of thick carbon steel plates. However, cutting quality is influenced by various factors such as nozzle selection, gas pressure adjustment, cutting speed, and defocus amount. To ensure optimal cutting results, users must pay attention to these key parameters and adjust them according to actual conditions.

Laser cutting quality is subject to a variety of factors, laser debugging depends on professionalism, experience, common sense, the user often encountered a variety of problems in cutting.

Different materials, different thickness of the cutting will also put forward different requirements for debugging, the following common processing materials carbon steel plate as an example.

Before cutting, ensure that the laser is in a normal working condition, in addition to pay attention to:

- Laser cutting head all lenses clean.

- The water temperature of the water tank is normal, no condensation on the laser.

- Gas purity is good, the gas path is smooth, no gas leakage.

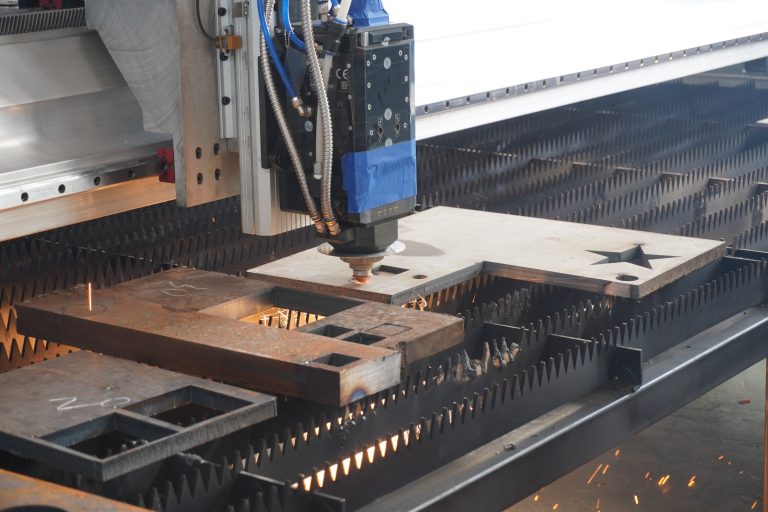

At present, high-power fiber laser is commonly used in high-speed high-bright surface carbon steel plate cutting, we take this as an example, mainly from the nozzle, gas pressure, speed, the amount of defocusing these dimensions to consider, on the frequent emergence of several types of process problems to be analyzed.

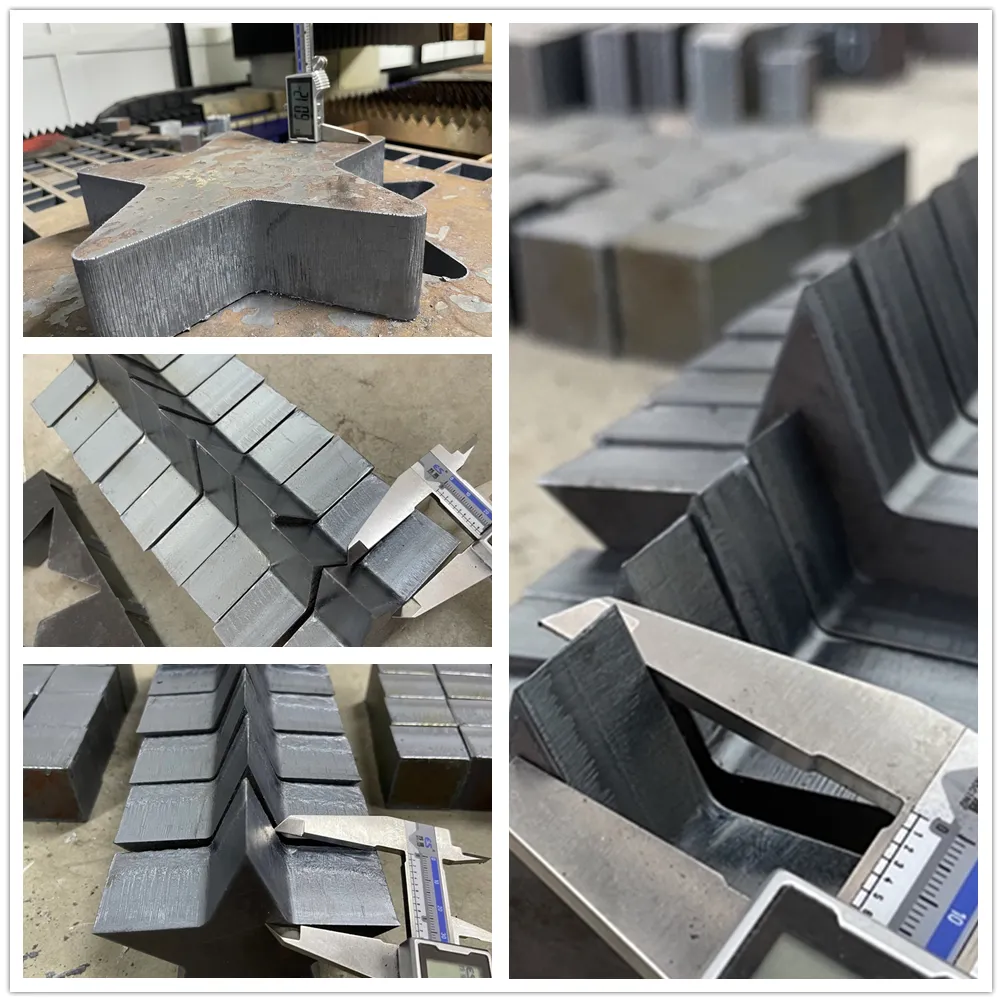

01.Burrs on the bottom

Troubleshooting:

- improper nozzle selection, replace with larger diameter nozzle to increase gas flow.

- negative focus mismatch, increase the negative focus, so that it penetrates the bottom position.

- insufficient air pressure leads to insufficient cutting, increase air pressure appropriately.

02. There is a ring of tumor slag at the bottom, which needs to be knocked out manually

Troubleshooting:

- improper nozzle selection, replace the nozzle with a larger diameter to increase gas flow.

- improper speed, do not rule out the cause of too fast, slow down the speed.

- poor quality of the plate, smaller diameter nozzle can not be good to eliminate the slag, it is recommended to use a better plate.

03.Deep cut grain

Troubleshooting:

- improper selection of the nozzle, replace the smaller diameter nozzle.

- air pressure is too large to cause overcooking streaks, reduce air pressure appropriately. 3.

- improper speed, too fast or too slow will lead to streaks appear overcooking. Suggest debugging speed, so that the power and speed to match.

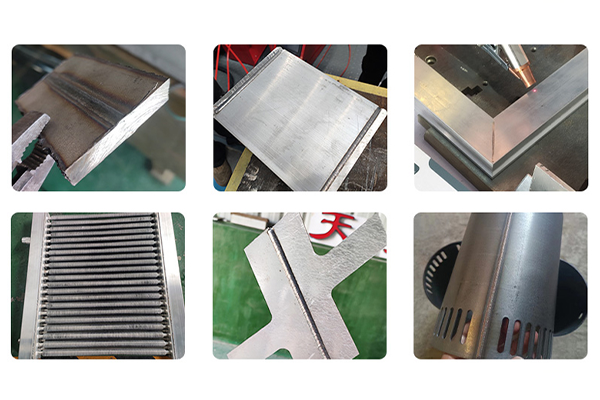

In conclusion, when cutting thick carbon steel plates, special attention should be paid to the cleanliness of the laser cutting head lenses, water tank temperature, gas purity, and the overall condition of the equipment. By selecting appropriate nozzles, adjusting gas pressure, and optimizing cutting speeds, common issues like bottom dross and deep cut surface textures can be effectively avoided. Glorious 10kW fiber lasers, featuring superior beam quality, stable mode output, and fully intelligent modular design, deliver faster, more precise, and cleaner cuts on thick plates. Built to IP65 standards for durability in harsh industrial environments, Glorious high-power lasers provide manufacturers with a reliable, energy-efficient solution for high-quality cutting — driving productivity, consistency, and operational excellence.

The rapid growth of the 10,000-watt laser market is an undeniable trend. As high-end equipment manufacturing advances at an accelerating pace, fiber laser cutting plays a pivotal role in enabling high-precision, high-efficiency metal processing.

Glorious 10,000-watt fiber lasers deliver exceptional beam quality and cutting finish, ensuring smooth, clean edges on thick plates. With stable beam mode, modular architecture, and fully intelligent control systems, Glorious lasers are engineered for peak performance. The entire enclosure is designed to IP65 standards, making it resistant to dust and moisture, and capable of withstanding extreme temperatures—ideal for demanding industrial environments.

Glorious ultra-high-power, energy-efficient solutions cut thick materials faster, more accurately, and with superior edge perpendicularity. Backed by advanced beam technology, Glorious lasers provide manufacturers with a powerful tool to enhance productivity, improve cut quality, and drive operational efficiency in heavy-duty fabrication applications.