With the development of automobile to the direction of low carbonization, diversification, intelligence, automobile lightweight has been the general trend. Laser welding technology as an important processing technology, will vigorously promote the process of automotive lightweight manufacturing. The use of laser welding technology can significantly improve the body’s impact resistance and anti-fatigue properties, improve the quality of the car. The world’s rapid development of laser technology, laser technology and equipment is becoming more mature, laser manufacturing costs continue to decrease. Laser welding has a fast welding speed, welding depth (laser welding depth to width ratio of up to 5:1), welding deformation is small, high degree of automation, non-contact long-distance welding characteristics, in the field of automotive parts manufacturing, especially in the automotive powertrain module, chassis module, body module and electronic systems and other automotive parts lightweight manufacturing on a wide range of applications.

1. Lightweighting, what can laser welding technology do?

The focus of automotive lightweight mainly focuses on: structural design, lightweight material application and the use of advanced manufacturing processes. Laser welding technology is the manufacturing process solution to realize automotive lightweight.

Laser welding technology was developed in the 1960s, this technology mainly relies on the energy density of the laser as a heat source, to complete the precision welding work. Unlike traditional welding technology, laser welding technology creates smaller weld seams, faster speeds, and less thermal strain, all of which are reasons why the technology has been used in automotive lightweighting. The application of laser welding technology in automotive lightweight research and development has the characteristics of low welding cost, high quality joints, and a wide range of use.

Laser welding technology is mainly used in automobile body-in-white roof laser automatic welding, multi-link gear laser welding, airbag igniter laser welding, sensor laser welding, battery valve laser welding and so on.

Almost all car manufacturers apply laser welding technology. Another important application of laser welding in automobile manufacturing is laser welding body frame. Laser welding is a continuous connection, which can make the strength and stiffness of the body increase; at the same time, the use of laser welding technology can reduce the amount of steel plate used to achieve the purpose of reducing the quality of the body. For example, the German Volkswagen 2004 5th generation Golf body, laser welding reached 70m.

2. Laser Welding Principles and Techniques

①Laser Welding Principle

The principle of laser welding is to use a high intensity laser beam to radiate directly to the metal surface, so that the welded place to form a heat source area of concentrated energy to make the welded material melt and form a solid weld and weld seam. There are two types of laser welding: pulsed laser welding and continuous laser welding. Pulsed laser welding is divided into heat conduction welding and laser deep fusion welding according to the welding principle, and is mainly used for single-point welding and welding of thin-walled materials. Continuous laser welding is mainly used for welding and cutting of thick plate materials. Laser welding also has certain limitations, for example, high requirements on the accuracy and surface quality of the parts, the weld seam is prone to loose and porosity and other quality defects.

②automotive parts manufacturing commonly used laser welding technology and process

- Laser self-melting welding: laser self-melting base material. Process characteristics: high speed welding, high precision, small heat input, small deformation, large depth to width ratio.

- Laser filler wire welding: laser + wire. Process characteristics: expand the laser welding range, improve the quality of weld formation, control the weld area organization properties.

- Laser remote welding: laser + scanning galvanometer. Process characteristics: alternative to the traditional spot welding, high speed, high precision, high spatial accessibility, can be welded multi-shape weld.

- laser – arc composite welding: laser + arc. Process characteristics: high adaptability, large depth of fusion, high strength, small deformation, high quality weld.

- laser brazing: laser + brazing material. Process characteristics: wetting the base material (not melted) to fill the joint, connecting and sealing the base material, beautiful molding.

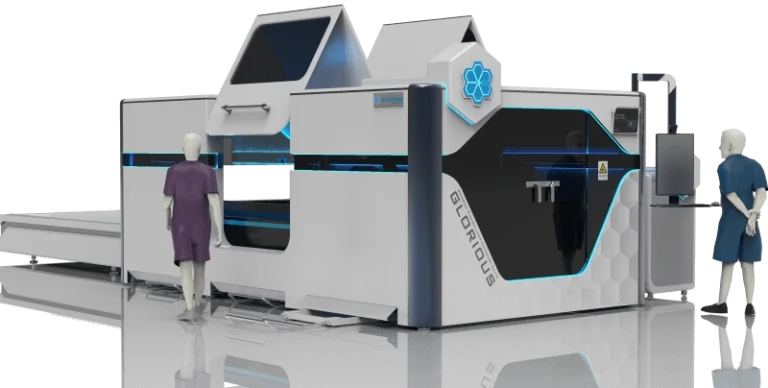

3. Welding Technology in Automobile Manufacturing-Six-Axis Robotic Welding Machine

- Mainly used for automobile body welding;

- Hardware configuration imported medium and high power laser is safe, stable and reliable;

- Extra red light correction, easy to try to teach the process of laser red light alignment, find the focus point;

- Flexible operation of the motion system, humanized design, better user experience.

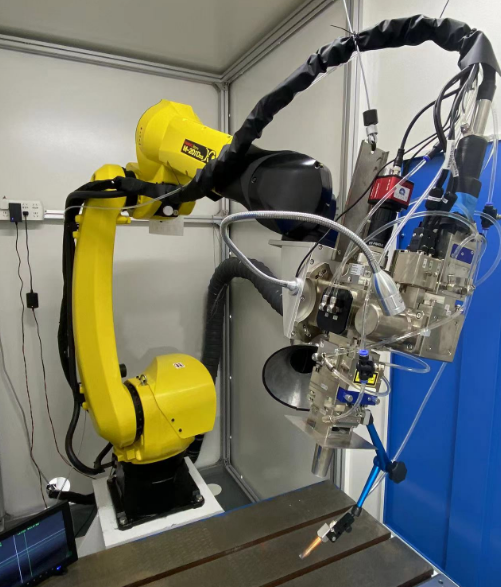

4. New Energy Industry

Batteries, motors, and electronic control are the three core components of new energy vehicles, from the manufacturing of automotive battery cores and PACK assembly, especially the power battery structure covers a variety of materials, such as steel and aluminum, as well as copper and nickel, etc. These metals may be made into electrodes, wires, shells, etc.. These metals may be made into electrodes, wires, shells, etc. And the materials are extremely thin, in the case of too large a heating area and too long a heating time, it is very easy to be deformed, resulting in poor welding. However, the Star Chain series welding robot can adapt to different non-ferrous metal welding, has the advantages of fast welding speed and short heating time, which can effectively solve the welding problems in this industry.

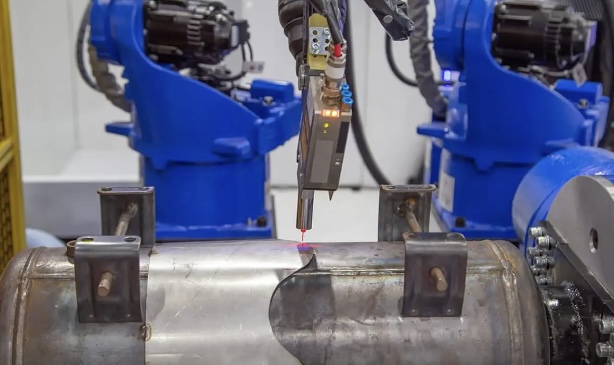

5. High Power Laser Welding Equipment

- Mainly used for welding in automotive industry, equipped with high power fiber laser;

- The worktable adopts a high-precision rotary table, which effectively ensures the stability and precision of the welding process;

- Adopting a 6-axis robot and an external axis, the six-station automatic welding saves the time of manual loading and improves the output at the same time;

- Equipped with intelligent camera and welding seam detection system can realize automatic tracking and online quality inspection of welding seam, which can observe the condition of welded products at any time.

6. reach a verdict

The application of laser welding technology in automobile manufacturing reflects its strong vitality and broad application prospects. Geely, Great Wall and other automobile manufacturing companies have adopted laser welding technology in some new models. In the foreseeable future and the new energy automobile market, laser welding technology will be widely used in the field of automobile manufacturing, helping the domestic automobile lightweight manufacturing technology progress and development.