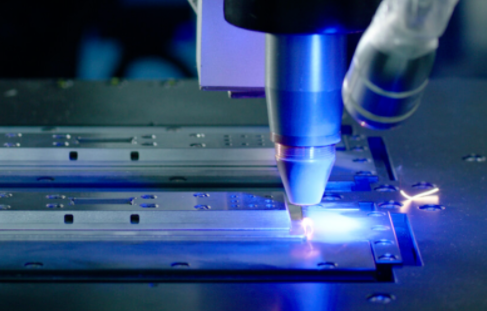

With the steady development of laser technology, fiber laser cutting machine with its automation and flexibility, gradually replaced the old-fashioned cutting and forming.

Now, metal laser cutting is becoming more and more popular. So what can fiber laser cutting machine do, can be widely used in which industries?

①Sheet Metal Processing Manufacturing Industry

With the booming development of sheet metal processing, the old-fashioned sheet metal cutting machine only to meet the current production process, cutting style conditions, but the metal laser cutting with a high level of flexibility, cutting work rate and other advantages, increasingly replacing the old-fashioned machine, metal fiber laser cutting machine widely used in the sheet metal processing industry is the inevitable trend of future development.

② Automobile Manufacturing

There are many precision parts in the automobile materials, such as automobile brake pads. In order to improve the safety of the car, it is necessary to ensure the precision of the cutting work. The old-fashioned manual precision is difficult to achieve, followed by low efficiency. Metal laser cutting has the advantages of high accuracy, high efficiency, no burr phenomenon, one-piece molding, etc., which is the reason why fiber laser cutting machine is widely used in the automobile manufacturing industry.

③ Crafts and gifts industry

With the development of science and technology is getting faster and faster, China’s metal crafts have been a certain development, metal fiber laser cutting equipment as an emerging processing tools for industrial production to improve efficiency, but also become a major highlight of industrial development, the combination of metal and high-tech, the alternation between the old and the new, so that the quality of metal crafts have been improved.

④ Decorative advertising industry

Laser cutting machine equipment can carry out the processing of some complex graphics, in the traditional technology can not be completed processing can also be realized to complete, for the decorative advertising industry to grow the processing of products, improve the market, the side for the enterprise to increase additional profits, no need for secondary rework, a complete operation efficiency, more stable customer resources.

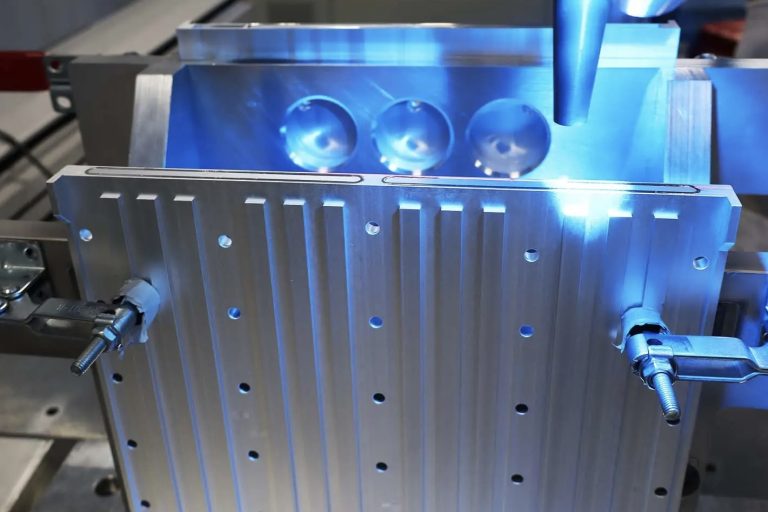

⑤ Kitchen equipment manufacturing industry

The old kitchen equipment manufacturing industry molding method is facing the problem of low efficiency, large consumption of molds, the use of huge costs. Fiber laser cutting machine cutting work rate is fast, high accuracy, improve the production processing productivity, can meet the personalized customization and differentiation of new product development, to cope with the kitchen equipment manufacturers many problems, access to the kitchen equipment manufacturers.

Compared with traditional processing, fiber laser cutting machine’s main features are: wide processing range, small deformation, high accuracy, environmental protection, automation, etc., is the obvious advantages of laser cutting equipment.

Furthermore, it also has the advantages of high efficiency, no appliance abrasion, differentiated style production and processing. Undoubtedly is the key to the widespread use of fiber laser cutting machine and manufacturing industry boom in the past few years.