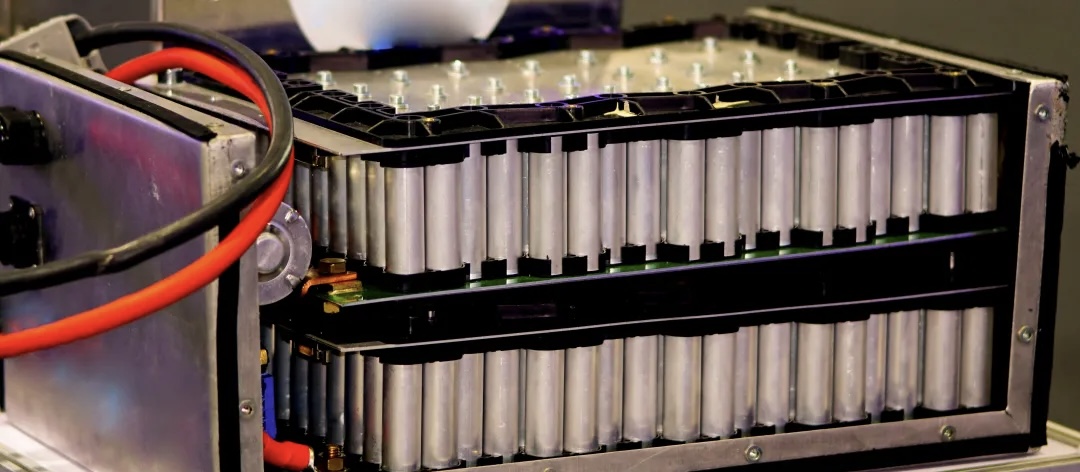

Producing safe battery modules is a critical step in the electric vehicle manufacturing process. Correctly connecting the battery to the bus bar ensures that the connection meets electrical requirements, which are critical to the vehicle’s functionality, performance and reliability. Most importantly, it is about passenger safety.

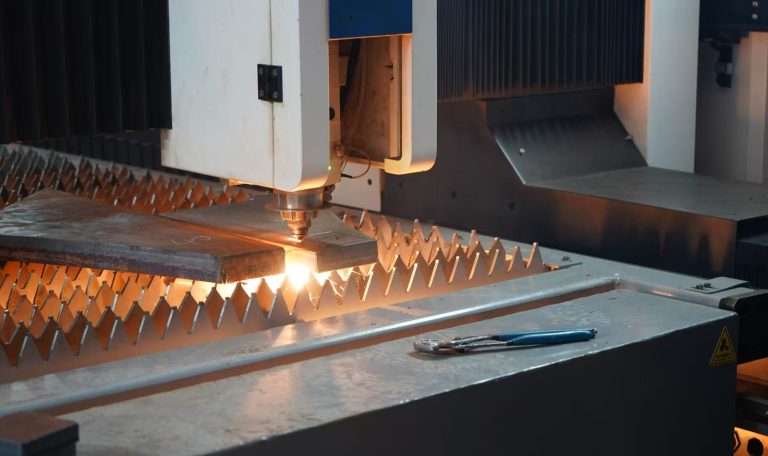

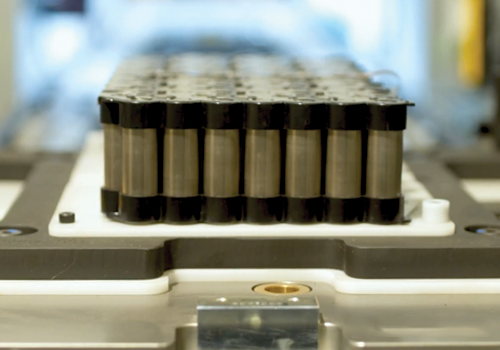

Cell modules are made by joining multiple cells (prismatic, cylindrical or pouch) together and welding them together using highly conductive bus bars. In order to produce these components with high quality, this process can be time-consuming, costly and inconsistent, all of which can lead to undesirable results. Tunable mode beam fiber laser welding solutions and real-time weld measurements provide excellent depth control and spatter-free welding, which are key requirements to ensure module quality and avoid potentially catastrophic defects.

Cell module production presents many overall manufacturing challenges, but specifically when it comes to busbar welding:

Challenge: Weld seam size has a direct impact on resistance

Solution: Laser welding provides precision and consistency, allowing welds to be controlled according to manufacturing specifications, resulting in uniform weld seam sizes.

Challenge: Material selection can involve different metals for bus bars and battery cells.

Solution: EV application specialists work with manufacturers to develop process parameters for welding dissimilar materials for optimal results.

Challenge: Weld position accuracy and weld depth penetration are critical

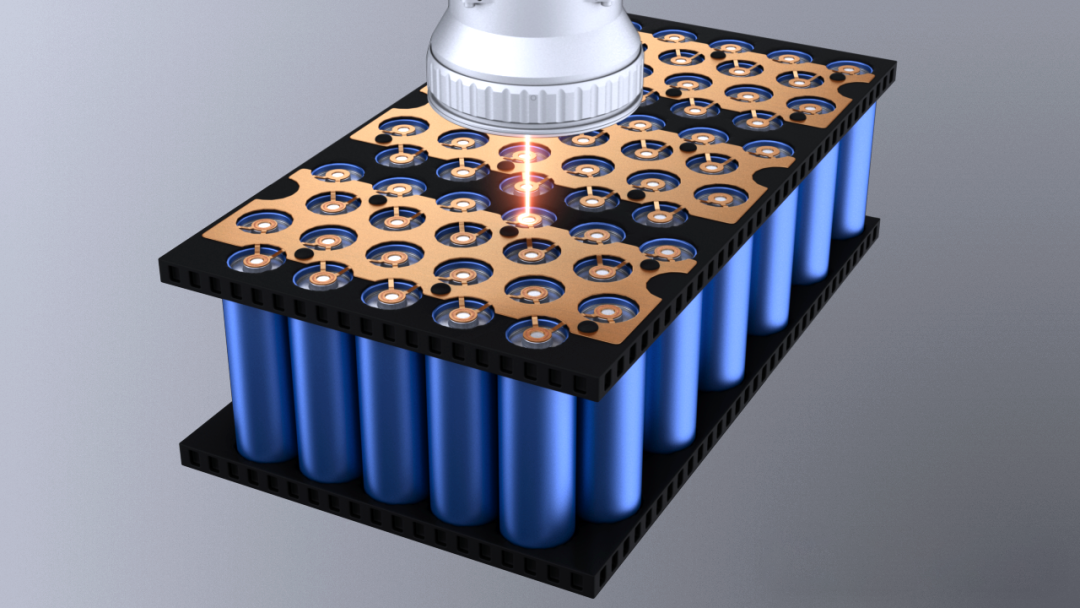

Solution: For cylindrical cells, laser welding solutions integrate real-time weld measurement to control weld depth and other critical welding parameters.

5 Advantages of Battery Busbar Welding

Laser welding has become the technology of choice for the automotive industry and electric vehicle applications due to several key benefits. Laser solutions for electric vehicles offer significant advantages that enable manufacturers to meet production requirements and deliver high-quality, safe battery modules.

- Laser welding is a non-contact process:

The materials used to manufacture battery modules (whether busbars or cells) are sensitive to defects. Laser welding does not come into contact with the material, thus eliminating the risks associated with traditional bonding methods. This is important because any defects in the material can affect the electrical performance of the battery module and the electric vehicle.

- Laser Welding is Highly Repeatable:

The tight process control employed in laser welding applies both within and between tools, making the busbar welding process repeatable and faster. Process consistency through control software and motion platforms enables laser power stability, eliminating weld variation, a key factor in busbar welding.

- High Laser Welding Productivity:

This is because laser welding has high tool uptime and availability, which allows for longer required maintenance intervals, whereas other methods require frequent attention to tool wear and consumables. By having a reliable source, laser welding ensures minimum downtime, which greatly increases productivity.

- Laser welding is easy to program:

This is especially important since multiple battery module designs already exist or are being created. The welding process can be easily programmed to accommodate different module designs and battery cell types.

- Laser welding is fast:

Laser welding is much faster than traditional methods due to easy programming and high repeatability. For cylindrical cells with thousands of connections, faster speeds mean significantly lower production costs.