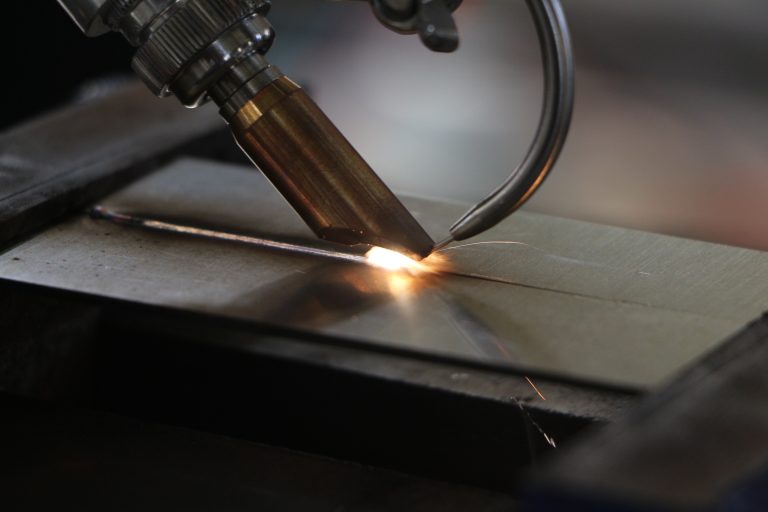

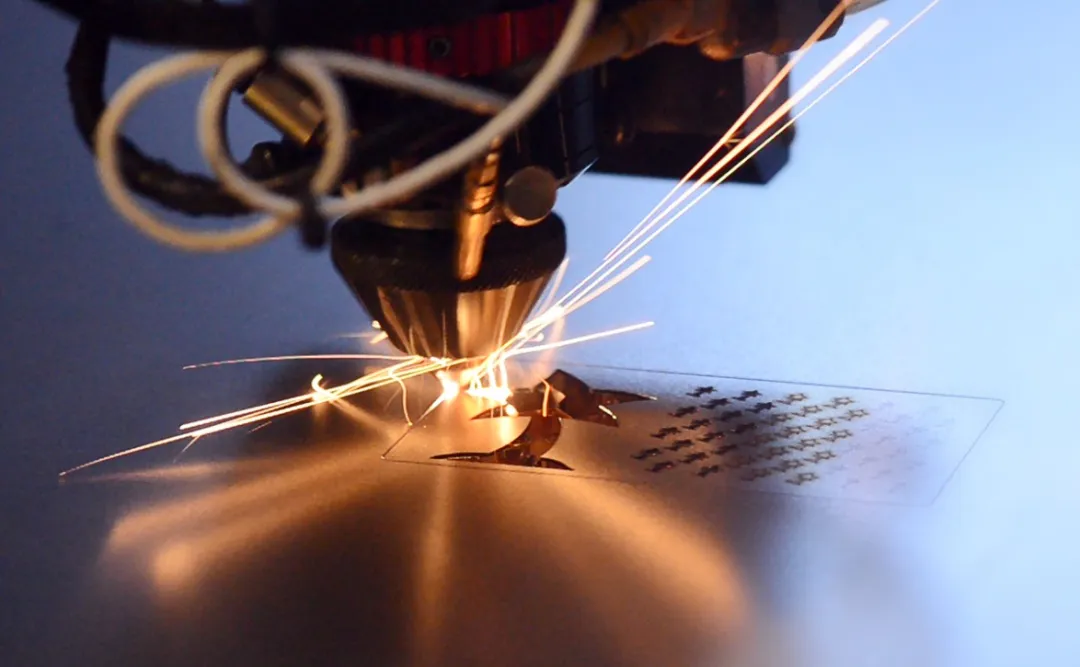

Laser welding belongs to the melting welding, with the laser beam as the energy source, impact on the weldment joint. Laser welding is a non-contact welding, the process does not require pressure, but the need to use inert gas to prevent oxidation of the molten pool, filler metals are occasionally used. Laser welding can carry out precise energy control, and thus can realize the welding of precision micro-devices, and it can be applied to a lot of metals, especially to solve some of the difficult to weld metal and dissimilar metal welding.

Laser brazing is a kind of laser welding technology, laser brazing welding principle: the use of laser beam as a heat source, focused beam irradiation on the surface of the filler wire, the wire in the beam energy continues to heat the formation of high-temperature liquid metal melting, liquid metal infiltration into the welded parts connection, in the appropriate external conditions, so that the formation of good metallurgical bonding with the workpiece. It should be noted that the connection between the workpieces is realized by brazing the molten metal, and the base material itself should not be severely damaged by laser fusion.

Advantages: high energy density, small deformation, very narrow heat-affected zone, high depth-to-width ratio of the weld, high welding speed, easy to realize automatic control.

Disadvantages: due to the focus diameter is very small, so the weld bridge ability is very poor; another laser energy conversion efficiency is low.

The laser brazing system mainly consists of laser generator and cooling system, laser brazing head, wire feeding mechanism, robot, tooling fixture, dust removal system, control system and so on.

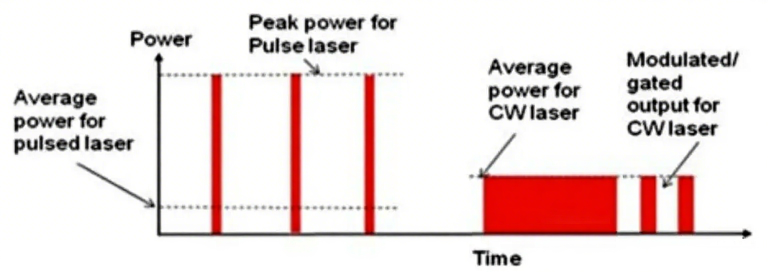

Laser generator and cooling system:The laser generator is the device that produces the laser light and is the equipment that provides the welding energy in the laser brazing system.

Laser brazing head: It mainly consists of collimation module, control module, focusing module, weld tracking module, air curtain module and other parts.

Wire feed system:The wire feeding system is responsible for stable wire feeding during welding. A push-pull wire feeding mechanism is used to ensure good alignment of the wire and stable wire feeding speed. If preheating is required, a hot wire power supply is added.

Robot: The motion system, which realizes the travel of the welding trajectory, carries the laser brazing head and ancillary devices, water and gas circuits, and so on. The robot is responsible for executing the welding process and talking to the automation system to call up the welding process parameters in the system.

Control System:The autonomous process cabinet controls the timing actions of the robot, laser, brazing head, wire feeder and preheating system through the industrial bus to complete the welding work. The PLC of the main production line exchanges signals with the robot via the industrial bus.

Laser welding in the automotive industry

Laser welding belongs to the melting welding, with the laser beam as the energy source, impact on the weldment joint. Laser welding is a non-contact welding, the process does not require pressure, but the use of inert gas to prevent oxidation of the molten pool, filler metals are occasionally used. Laser welding can carry out precise energy control, and thus can realize the welding of precision micro-devices, and it can be applied to a lot of metals, especially to solve some of the difficult to weld metal and dissimilar metal welding.

Due to the laser welding speed, easy to realize remote control and automated production, so it is more used in automobile manufacturing and new energy battery production and other high degree of automation in the industry, with the development of new energy automobile market in recent years, but also led to the market demand for laser welding equipment. Data show that during 2013-2019 the market size of China’s laser welding equipment rose from 1.56 billion yuan to 10.13 billion yuan.

The main application processes in the automotive industry mainly include laser splicing welding of unequal thick plates, laser group welding of body assemblies and sub-assemblies, and laser welding of automotive parts. And in the field of power battery explosion-proof valve sealing welding, pole ear welding, flexible connection welding, safety cap spot welding, battery shell sealing welding, module and PACK welding and other processes, are laser welding as the best process.

Laser welding technology in the automobile body application, can do to reduce the weight of the body to achieve the purpose of saving fuel; laser welding technology of solidity and lightweight, can improve the degree of integration of the body; laser welding technology of high precision and high efficiency characteristics, can be in the production of high efficiency at the same time to ensure its safety and stability. When the car is traveling due to the bumps on the ground extrusion, each part and structure are bearing different degrees of impact, which requires the car’s overall structural precision strength to be very high. The use of laser welding technology, its dynamic and static stiffness than other welding processes can be improved by more than 50%, reducing the noise and vibration in the driving process, improving the comfort of the ride, but also enhance the safety performance of the car.

1.Body welding

laser welding in the automotive industry is used in a large number of body stamping parts assembly and connection. The main applications include roof laser welding, trunk lid laser welding and frame laser welding; another more important body laser welding applications, is the body structure parts (including doors, body side frame and column, etc.) of the laser welding.

The reason for the use of laser welding is to improve the strength of the body, and can solve some parts are difficult to implement the conventional resistance spot welding problems. Laser self-melting welding, that is, the welding of two or more parts of their own melting to form a whole, without the addition of wire and other auxiliary materials, more than one part of the welded self-melting into a whole.

Laser self-melting welding in automobile body manufacturing is mainly divided into two major parts, body group welding and welding.

Body group welding: body group welding mainly has a roof and side columns, rear fenders, body brackets and door welding, with the demand for product replacement, laser welding is more and more widely used in the field of automotive, group welding has been accepted by the majority of manufacturers, at present, only Volvo is still insisting on the use of laser self-melting welding; side enclosure Ford SUV and sedan respectively, there is a use of laser self-melting welding, Volkswagen, many models are also in the use of Use.

2.Unequal Thickness Laser Welded Plates

The use of unequal thickness laser welded plates for car body manufacturing can reduce the weight of the body, reduce the number of parts, improve safety and reliability and reduce production costs; welded plates are welded from steel with different strengths, thicknesses and coatings, and laser welding has been widely used because of its fast speed, high precision and small weld seams, and most of the current automotive welded plates are made of laser welding. Compared with the old body of pure steel plate, welding plate has three advantages, light weight body, using the welding method to make the plate thinner, so as to reduce the weight of the body; high overall strength, the body through the welded plate composition, the strength of the body even more than the parent material body, increasing the safety of the car body; the cost is relatively low, the welding strength, accuracy is higher than the traditional materials, reducing the use of parts at the same time to ensure the performance. The use of laser welding plate applied to the body manufacturing, can reduce the number of parts, molds and welding fixtures, reduce the weight and cost of the body, and improve the competitiveness of the product market. The main application of weld plate in the automobile body, mainly used in the majority of cover parts, but also used in some structural parts.

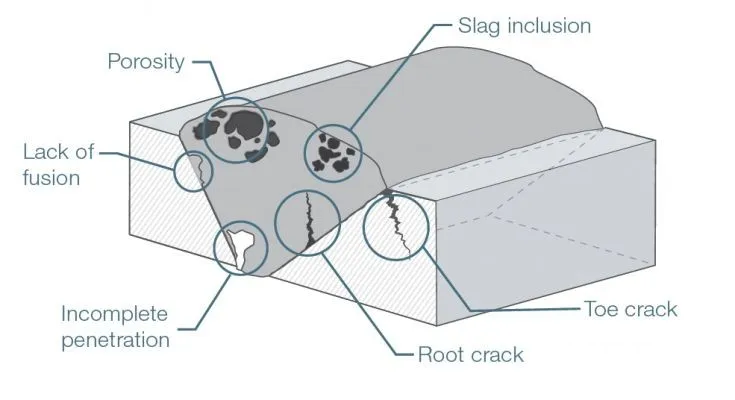

There are three main types of weld seams in automotive panels: single straight line welds; plural straight line welds; and non-straight line welds. Among them, the single straight line weld type is the most widely used, and the production process is relatively simple. Non-linear weld is the most complex, generally according to the shape of the stamped part after molding design weld, so as to improve the strength of the product and stamping performance. Since automotive weld plates are subsequently stamped and molded, the molding quality and defect control requirements for weld plates are particularly strict. Mainly includes the appearance (scars, cracks, inclusions, holes and scratches, etc.), weld formation (weld width, weld lump protrusion, effective depth of the weld, the backside of the fracture and weld misalignment, etc.) and mechanical properties, such as (tensile, cupping, hardness and bending of the weld and other tests) requirements. For example, it is required to break in the non-welded area in the tensile properties test, and in the cupping test the area of cracking must not be in the weld or the cupping value is greater than the specified value.

3.Welding of gears and transmission parts

In addition, a wide range of transmission parts can be welded on this machine, especially differential cases and driveshafts in car transmissions, which are often welded together after the production of individual parts.

Advantages of laser welding automobile bodies

1.The most important advantage of non-contact processing laser welding in automobile manufacturing is reflected in the advanced non-contact processing method. Traditional processing methods such as screw fastening and gluing are not able to meet the requirements for precision and robustness in modern automobile manufacturing, and the application of new materials also makes traditional processing methods slightly inferior. Laser welding is non-contact, in the process of processing, can not touch the product to achieve precision welding, in the connection of the robustness, seamlessness, precision and cleanliness of the process to achieve leapfrog progress.

2.Laser welding to enhance automotive lightweight using laser welding can be used in automotive manufacturing with more stamping parts instead of casting parts, with continuous laser weld instead of dispersed spot weld, you can reduce the lap width and some of the reinforcing parts, reduce the volume of the body structure itself, thus reducing the weight of the body, to meet the automotive energy-saving emission reduction requirements.

3.Enhance the body assembly precision and rigidity of a car body plus chassis with hundreds of thousands of parts, how to connect them together on the rigidity of the car body has a direct impact on the use of laser welding can be almost all the different thicknesses, grades, types and grades of metal materials are connected together, the precision of welding and the assembly precision of the body is greatly improved, the stiffness of the body is increased by more than 30%, thereby improving the safety of the car body. The safety of the body is improved.

4.Laser Hybrid Welding Enhances Process Stability Compared to pure laser welding technology, utilizing laser hybrid welding technology greatly improves the ability to connect the seams of sheet metal parts, thus allowing companies to more fully utilize the process stability of arc welding when welding at high laser speeds.

Nowadays, laser welding applied to the production of automobile body has become a trend, the use of laser welding can not only reduce the weight of the body, improve the accuracy of the assembly of the body, but also greatly strengthen the strength of the body, in the user to enjoy the comfort at the same time, to provide a higher level of security. Auto parts laser welding machine adopts robot intelligent operation, through the collimator mirror collimated parallel light, focusing on the workpiece to implement the welding of a laser equipment. With a simple universal instrument, can be difficult to access the large mold welding precision parts, the implementation of flexible transmission of non-contact welding, with greater flexibility in operation.