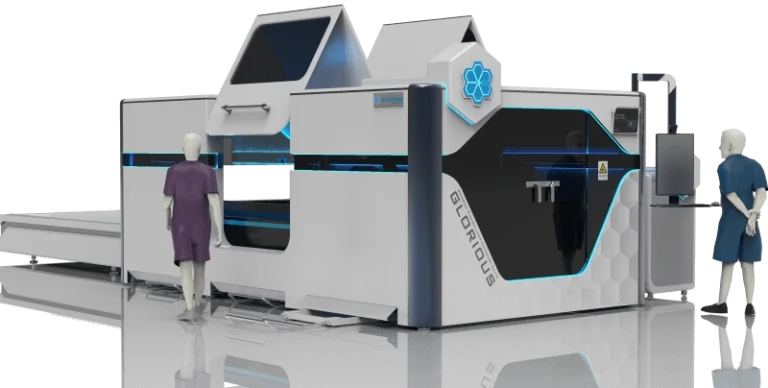

Laser cutting technology must not be unfamiliar to everyone, laser cutting technology is a use of high energy density of the laser beam on the material for accurate cutting processing methods, widely used in the processing of metal and non-metallic materials in the field, the most common laser cutting equipment such as laser cutting machine.

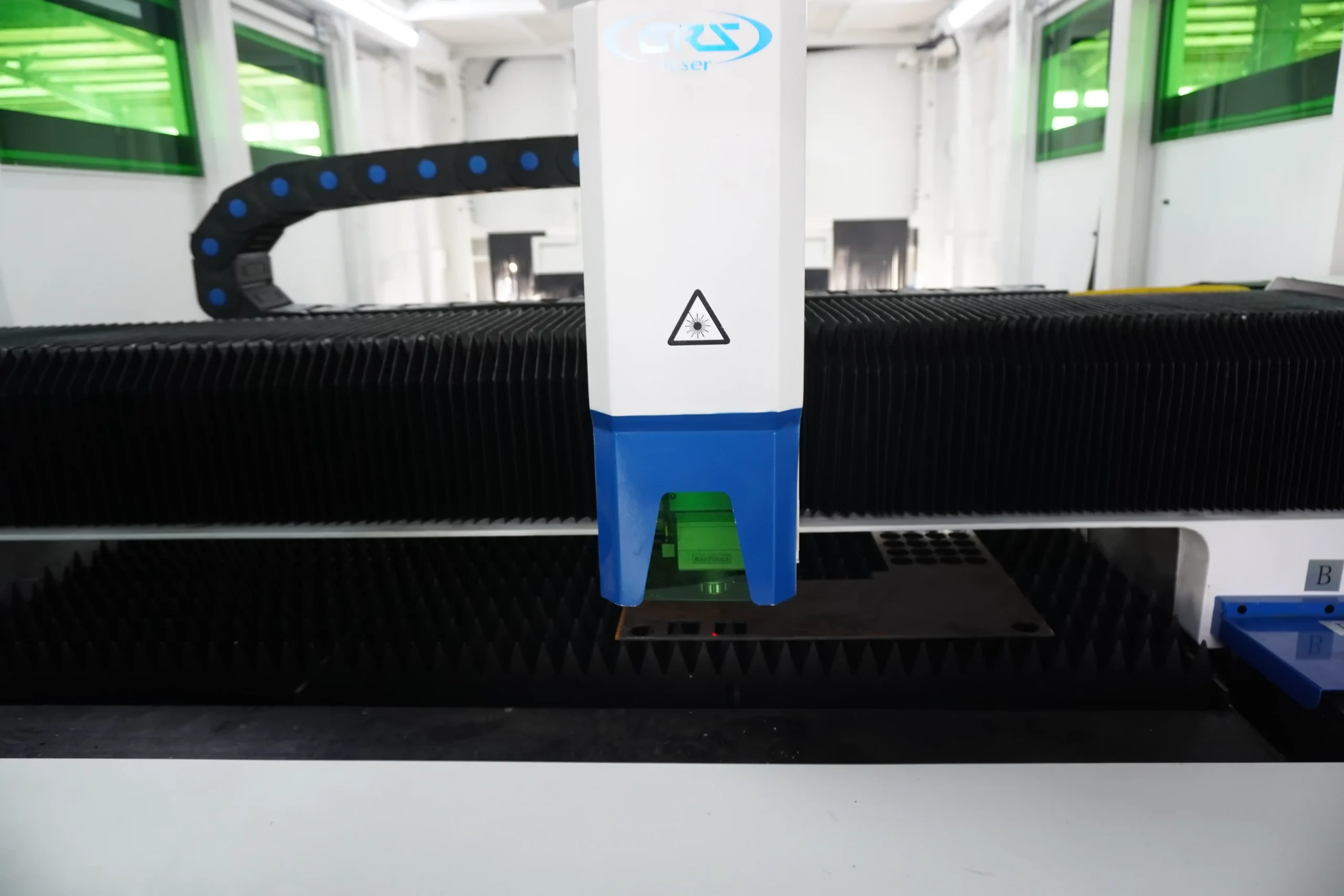

The laser cutting machine utilizes the cutting principle of laser. The core of laser cutting lies in the laser beam generated by a high-power laser, which is focused into an extremely small spot, usually only a few tens of micrometers to a few hundred micrometers in diameter, through a system of mirrors and lenses, especially focusing lenses, to create a very high energy density on the surface of the material being processed.

Under the irradiation of a high energy density laser, the surface of the material is rapidly heated to thousands to tens of thousands of degrees Celsius, resulting in instantaneous melting, vaporization or combustion reactions. In the case of metallic materials, this may be accompanied by an oxidizing reaction.

In the laser cutting process, often with the use of high-pressure auxiliary gases (such as oxygen, nitrogen, argon or compressed air, etc.), on the one hand, to help blow away the molten or vaporized material, on the other hand, play a role in protecting the cutting area, reduce the heat-affected zone, improve the cutting quality and speed.

The main process parameters for laser cutting are laser power for cutting, kerf width, cutting speed and gas flow. Other factors, such as laser beam quality, lens focal length, the amount of out-of-focus and nozzle for laser cutting also has a great impact.

(1) Laser power

The amount of power required for laser cutting is determined by the nature of the material and the cutting mechanism. For example, cutting materials with high surface reflectivity and good thermal conductivity, as well as cutting materials with high melting point, require larger laser power and power density. With different cutting . Cutting the same material with different cutting mechanisms, the power required is also different, the power required for vaporization cutting is the largest, followed by melting cutting, oxygen-assisted melting cutting requires the smallest power. With the increase in plate thickness, the required laser power increases.

(2) Cutting speed

Under certain power conditions, the thicker the plate, the slower the cutting speed. Cutting speed also has a greater impact on the surface roughness of the kerf. Research shows that the relationship between the kerf surface roughness and cutting speed is U-shaped change, different plate thickness of the material, different cutting gas pressure, there is an optimal cutting speed, cutting at this speed, the kerf surface roughness value is minimized. Generally speaking, the faster the cutting speed, the greater the power required.

(3) Pressure of gas (gas flow)

The gas blown during cutting has the following functions: in melting cutting, it relies on the pressure of the blown gas to blow away the liquid metal and form the kerf. In oxygen-assisted melting cutting, the gas reacts with the cutting metal and releases heat, providing part of the cutting energy, while at the same time relying on the gas to blow away the reactants. However, the gas also has a cooling effect on the material, which will take away part of the energy from the cutting zone. Therefore, the effect of gas on the cut quality is twofold. Gas flow and nozzle form also has a relationship, different nozzles, the use of different gas flow. In the power and cutting material plate thickness, there is an optimal cutting gas flow, which is the fastest cutting speed. As the laser power increases, the optimal flow of cutting gas increases.

(4) beam quality, lens focal length and defocusing amount

The mode of the laser output beam is based on the transverse mode when the laser cutting is most favorable. In this way, it is possible to obtain a small spot and high power density by focusing. Experimental studies have shown that the kerf width is almost equal to the laser spot diameter in non-oxygen assisted cutting. The spot size is proportional to the focal length of the focusing lens. Short focal length of the lens can get a smaller spot, but the depth of focus is very small. It should be noted that: unlike geometric optics, the focal depth used in laser processing technology is defined as follows: if the power density at the center of a cross-section of the beam is 1/2 of that at the focal point, the distance between this point and the focal point is called the depth of focus. The smaller the depth of focus, the thinner the plate thickness that can be cut, and the more stringent the distance from the surface of the workpiece to the lens. When cutting thick plates, the focusing lens with a larger focal length should be used. The amount of focus on the cutting speed and cutting depth has a greater impact on the cutting process must remain unchanged, the general amount of focus to choose a negative value, that is, the focus position is placed on the cutting plate surface below a certain point.

(5) Nozzle

Nozzle is an important part of the laser cutting quality and efficiency. Laser cutting generally use coaxial (airflow and optical axis concentric) nozzle, nozzle outlet diameter size should be based on the thickness of the plate to choose. In addition, the distance from the nozzle to the surface of the workpiece also has a greater impact on the quality of the cut, in order to ensure the stability of the cutting process, this distance must remain constant.

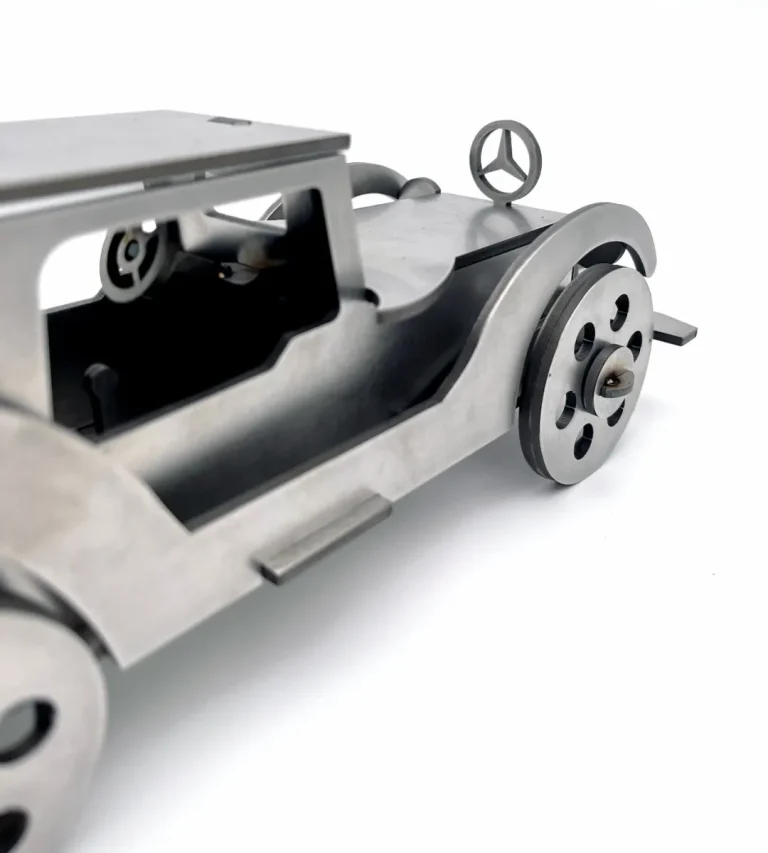

Laser cutting of industrial materials

(1) Laser cutting of metallic materials

Almost all metal materials have high reflectivity to infrared light at room temperature. For example, the absorption rate of 10.6μm carbon dioxide laser is only 0.5%~10%. However, when a focused beam with a power density of more than that is shone on a metal surface, it can start melting the surface in microseconds. The absorption of most metals in the molten state rises dramatically, typically to 60% to 80%. As a result, CO2 lasers have been successfully used in the practice of cutting many metals.

The maximum thickness of carbon steel plate that can be cut by modern laser cutting systems has exceeded 20mm. The slit for cutting carbon steel plate using the oxygen-assisted melting cutting method can be controlled to a satisfactory width, and the slit can be as narrow as about 0.1mm for thin steel plates. Laser cutting for stainless steel plate is an effective means of processing, it can control the heat-affected zone in a small range, so as to maintain its corrosion resistance well. Most alloy structural steel and alloy tool steel can be laser cutting method to get a good quality of the cut edge.

Aluminum and aluminum alloys can not be cut with oxygen-assisted melting, to use the melting cutting mechanism, aluminum laser cutting requires a very high power density to overcome the high reflectivity of the 10.6μm wavelength of the laser. 1. 06μm wavelength YAG laser beam due to the high absorption rate, can significantly improve the cutting quality and speed of aluminum laser cutting.

Titanium and titanium alloys commonly used in the aircraft manufacturing industry, the use of oxygen as an auxiliary gas when the chemical reaction is intense, cutting speed is faster, but easy to form an oxide layer on the cutting edge, and even cause overcooking. The use of inert gas as an auxiliary gas is more stable, can ensure the cutting quality.

Most nickel-based alloys can also be implemented oxygen-assisted melting cutting. Copper and copper alloy reflectivity is too high, basically can not use 10.6μm carbon dioxide laser cutting.

(2) Laser cutting of non-metallic materials

10.6μm carbon dioxide laser beam is easily absorbed by non-metallic materials, its low reflectivity and evaporation temperature so that almost all the absorbed light energy into the material inside, and in the instant caused by the formation of holes in the vaporization of holes into the cutting process of the virtuous cycle. Plastic, rubber, wood, paper products, leather, natural fabrics and other organic materials can be cut by laser. However, the thickness of the wood needs to be limited, the thickness of the board within 75mm, laminates and chipboard about 25mm. inorganic materials in the quartz and ceramics can be cut with a laser, the latter is suitable for controlled fracture cutting and can not be used with high power. Glass and stone are generally not suitable for laser cutting.

Other materials that are difficult to process by conventional methods, such as composite materials, hard alloys, etc., can be cut by laser, but it is necessary to experimentally select a reasonable cutting mechanism and process parameters.

In the actual application of laser cutting technology, enhancing cutting efficiency, improving cutting quality and reducing cutting cost is one of the things we often need to consider.

Enhancement of laser cutting technology to improve productivity, cutting quality and reduce costs can start from the following aspects:

1, with the progress of laser technology, the use of higher power laser (such as 10,000 watts) can significantly increase the cutting speed, while reducing the heat-affected zone and material deformation, making the cutting more efficient and better quality, especially for thicker materials cutting.

2、Reasonable adjustment of laser power, cutting speed, auxiliary gas type and pressure, the distance between the nozzle and the material and other parameters, according to the specific material and cutting requirements for the refinement of the settings, through a number of tests to find the optimal combination of parameters, can improve cutting efficiency and quality.

3, through the automatic focusing system, according to the material thickness and type of automatic adjustment of the laser focus position, to ensure cutting accuracy.

4、Reduce the non-cutting time and improve the overall operation efficiency by quickly moving the cutting head to the next cutting starting point.

5、Automatically detect the material edge and tilt angle, automatically adjust the cutting path, reduce material waste and pre-treatment time.

6、Use CNC software to simulate cutting, plan the most concise cutting path, reduce empty travel, improve material utilization and cutting speed.

7、Regular maintenance and repair of the laser cutting machine, such as replacing wearing parts, cleaning optical components, calibrating equipment, etc., can ensure long-term stable operation of the equipment and maintain the best cutting performance.

8, keep the working environment of the laser cutting machine clean, suitable temperature, moderate humidity, to avoid dust and high humidity on the equipment and cutting effect.

9、Adopt more advanced CNC control system and software to improve control accuracy and response speed to support more complex cutting tasks.

10、Continue to pay attention to new advances in laser technology, such as more efficient laser sources, more advanced optical systems, intelligent software algorithms, etc., in order to continuously improve the cutting ability.