Laser mold welding machine, laser mold refinishing machine, this kind of laser mold burner is universal laser launched suitable for steel mold, aluminum mold refinishing.

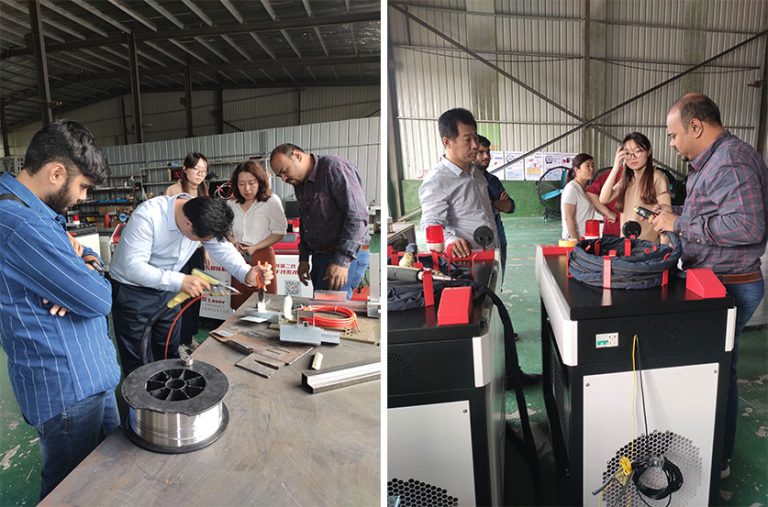

Advantage: unique overall structural design, suitable for a variety of small, medium and large mold repair.

Small mold repair.

- Parameter adjustment adopts intelligent remote control, simple and fast operation.

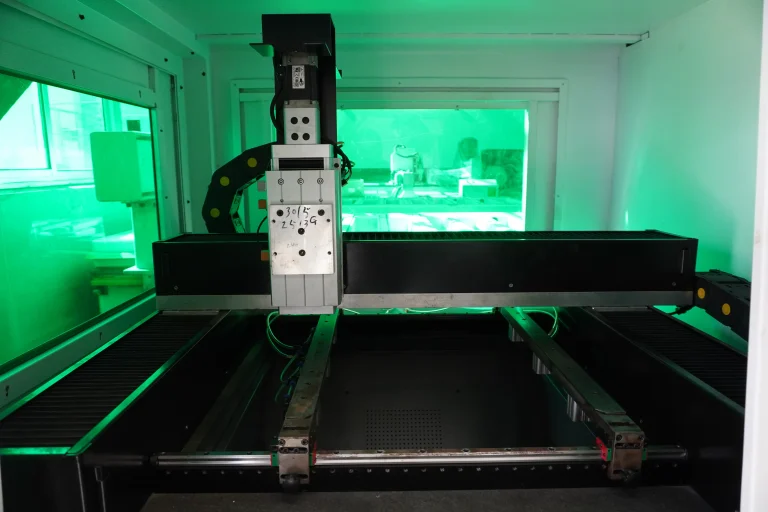

- The table can be motorized lift, three-dimensional movement, easy to operate.

Industry applications and applicable materials: suitable for medium and small mold repair welding. Commonly used in cell phones, digital products, glasses, toys and other mold manufacturing and molding industry.

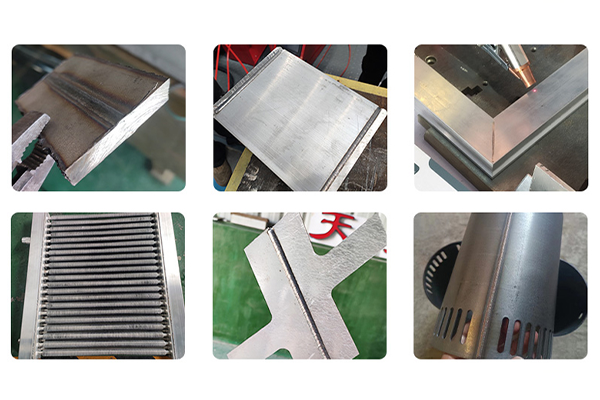

Manufacturing and molding industry. Mending welding of various mold steel, stainless steel, cymbal steel, precious metals and very hard materials. Precision injection molding, die-casting, mold

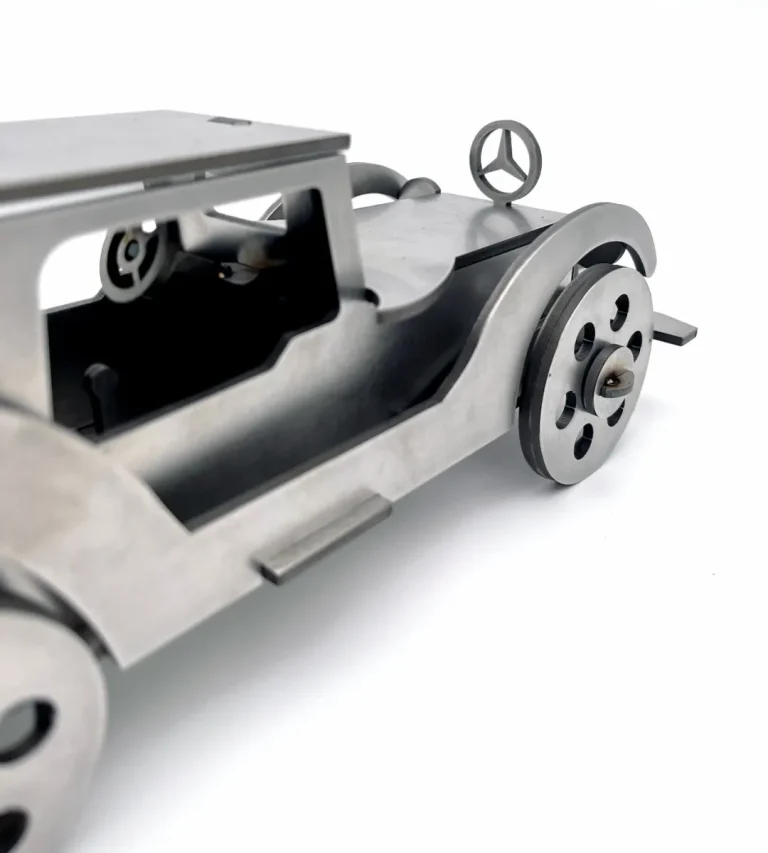

Repair metal jewelry and accessories, precision stamping parts welding, lost wax castings, aluminum castings, stainless steel products, sand holes.

3. The use of imported ceramic spotlight cavity, life (6-8) years, corrosion resistance, high temperature resistance, xenon lamp life of more than 9 million times.

The laser head can be rotated 360 degrees, the optical path part can be rotated 360 degrees, as well as up and down motorized lifting, front and back push, suitable for a variety of repair.

The most advanced shading system, eliminating eye irritation and injury during working hours.