In fiber laser cutting applications, the relationship between laser power, cutting speed, and material thickness is critical to processing efficiency and cost-effectiveness. Choosing the right power level impacts not only cut quality but also overall equipment value. This article analyzes real-world cutting data for carbon steel and stainless steel, comparing performance across 500W, 1000W, and 2000W fiber laser cutters. Results show: high power significantly boosts speed on thin sheets (<2mm), but the gap between 1000W and 2000W narrows on thicker materials, while 500W struggles beyond 2mm. Through detailed comparison, we reveal that the 1000W fiber laser cutter offers the best balance of speed and cost, making it the most cost-effective choice for most industrial applications.

The Relationship Between Fiber Laser Cutting Power, Speed, and Material Thickness

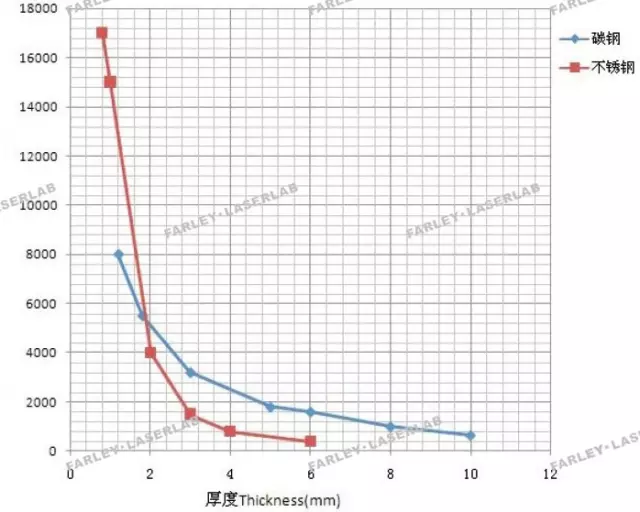

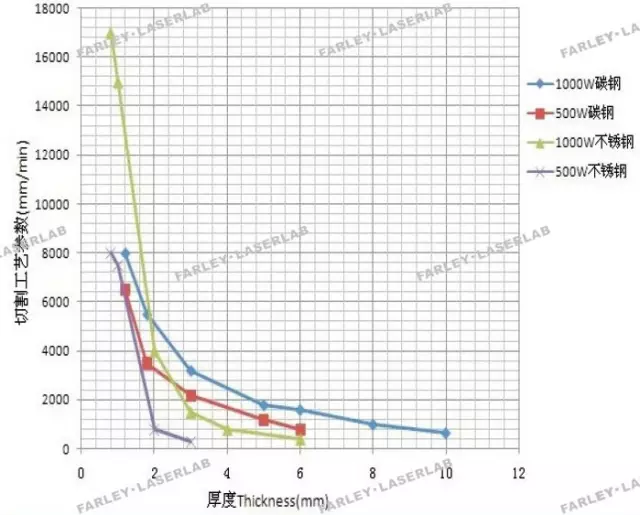

Let’s take carbon steel as an example. As shown in Figure 1, using a 1000W fiber laser cutting machine, for carbon steel materials under 10mm thickness:

- When the thickness is less than 2mm, the maximum cutting speed can reach up to 8 meters per minute.

- At 6mm thickness, the cutting speed is approximately 1.6 meters per minute.

- At 10mm thickness, the speed drops to about 0.6–0.7 meters per minute.

Now, refer to Figure 2, which shows a 2000W fiber laser cutting machine:

- For 1mm carbon steel, the maximum cutting speed can reach 10 meters per minute.

- At 6mm thickness, the speed is approximately 2 meters per minute.

- At 10mm thickness, the speed is around 1 meter per minute.

From this, we can see that for carbon steel thinner than 2mm, manufacturers who prioritize cutting speed may consider using a 2000W fiber laser cutter. However, 2000W machines naturally come with higher equipment costs and operating expenses compared to 1000W models. For materials thicker than 2mm, the cutting speed advantage of a 2000W machine over a 1000W model is relatively small. Therefore, in a comprehensive comparison, the 1000W fiber laser cutting machine offers higher cost-effectiveness than the 2000W option.

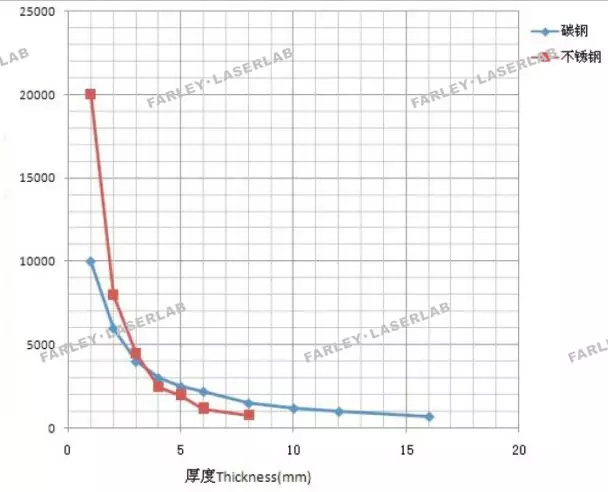

Now, let’s compare the cutting parameters of 500W and 1000W fiber laser cutters, as shown in Figure 3. Again, using carbon steel as the example:

- For carbon steel under 2mm, the maximum cutting speed with a 500W machine is about 6.6 m/min, while the 1000W machine can reach 8 m/min.

- For 6mm carbon steel, the 500W machine cuts at approximately 0.8 m/min, while the 1000W machine reaches 1.6 m/min—a clear performance gap that follows the same trend for other thicknesses.

Next, let’s examine stainless steel. As shown in the data:

- For stainless steel under 2mm, the 500W machine achieves a maximum speed of about 8 m/min, while the 1000W machine can reach around 17 m/min.

- For 3mm stainless steel, the 500W machine cuts at approximately 0.4 m/min, while the 1000W machine reaches about 1.4 m/min—a significant difference.

In conclusion, when comparing 500W vs 1000W fiber laser cutters, the 1000W model is clearly the smarter and more capable choice for both carbon and stainless steel processing.

Key Takeaways:

- Higher power = higher speed on thin materials, especially noticeable in stainless steel.

- Diminishing returns on thick plates: The speed gap between 1000W and 2000W narrows significantly beyond 2mm.

- 1000W strikes the best balance between performance, stability, and cost for most industrial applications.

- 500W is limited in medium-to-thick plate processing and not suitable for high-efficiency production.

Subscribe to “Laser Cutting Technology” for more updates on laser processing techniques!

Articles on laser material processing are continuously being updated.

Feel free to share and republish with proper attribution.