Fiber lasers are widely used in industrial cutting applications, but their cutting efficiency can gradually degrade due to various hidden factors. This article dives deep into the five key hidden causes behind fiber laser performance decline and offers professional detection insights to help users enhance equipment stability and productivity.

Characteristics of fiber laser

Fiber lasers are lasers that use optical fibers as the main working medium and have many unique advantages and features:

High efficiency: Fiber lasers usually have very high electro-optical conversion efficiencies, which enable them to convert input electrical energy into laser output more efficiently than conventional solid-state or gas lasers.

Good beam quality: Due to the characteristics of the fiber itself, fiber lasers can provide very high beam quality (M² value close to 1), which makes them widely used in fine machining, medical surgeries and other fields.

Compact design: Fiber lasers are relatively simple and compact, making them easy to integrate into existing systems. Its small size also means it takes up less space, making it easy to install and maintain.

Good stability: Fiber lasers are insensitive to changes in environmental conditions, such as temperature changes, and therefore have good stability and reliability.

Long life: fiber lasers using semiconductor pump sources usually have a very long service life, pump diode life of up to tens of thousands of hours or more.

Variety of wavelengths: By choosing different doping elements and fiber types, a variety of wavelengths from the ultraviolet to the mid-infrared range can be achieved to meet the needs of different applications.

Easy Heat Dissipation: Because the fiber has a large surface area to volume ratio, the heat generated during the operation of the fiber laser can be easily dissipated, reducing the risk of performance degradation due to overheating.

Expandability: Through the beam combining technology, the power expansion of fiber laser can be easily realized to meet the industrial demand for high power laser.

Advantages of fiber laser in cutting

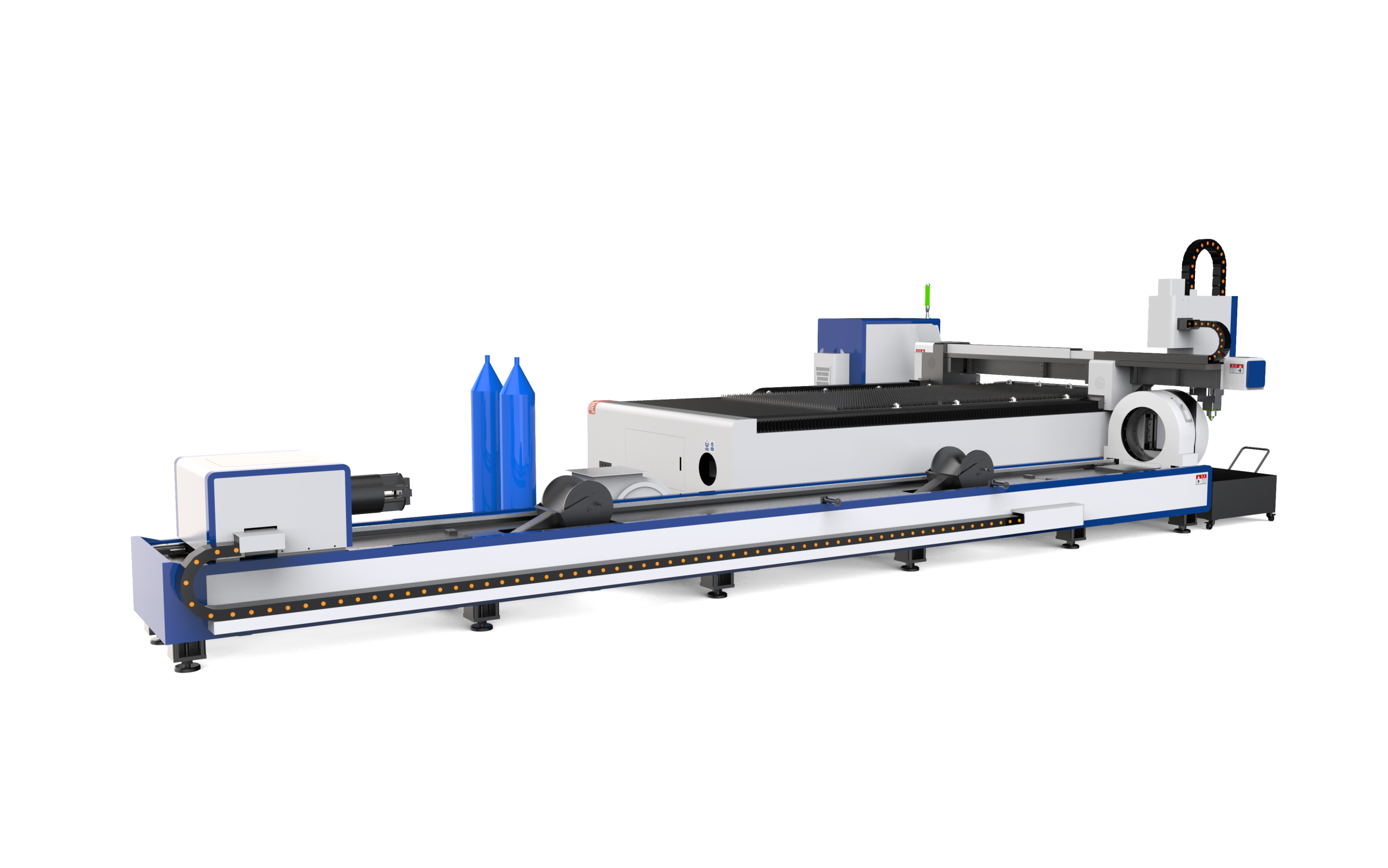

Many laser cutting machine equipment will use fiber laser as the core component, what is the reason for this, here we have to mention the advantages of fiber laser in cutting.

Fiber lasers have several advantages in cutting applications, as follows:

High precision: fiber lasers can be focused to a very small point (up to 25 microns), providing extremely high cutting precision and smaller heat-affected zones, making the kerf finer and smoother.

High Speed: Fiber laser cutting machines are 2-3 times faster than CO2 lasers of the same power in sheet metal cutting. This means higher productivity and faster processing cycles.

Low Maintenance: Fiber lasers use optical fibers to deliver the beam, eliminating the need for complex optical alignment, reducing maintenance requirements and making operation easier.

Low Operating Costs: Fiber lasers typically have photoelectric conversion efficiencies in excess of 30%, compared to 5% to 15% for CO2 lasers and even less for solid state lasers, which results in significant reductions in energy consumption and operating costs over the long term.

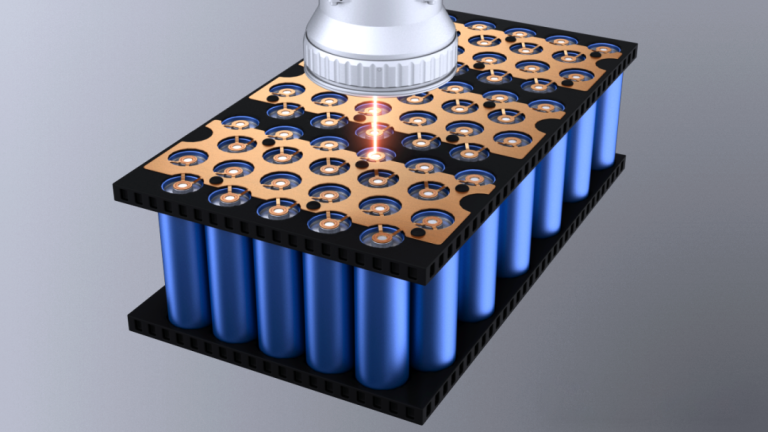

Wide material applicability: Fiber lasers are capable of processing a wide range of metal materials, including carbon steel, stainless steel, copper and other highly reflective materials, which is very suitable for sheet metal manufacturing, 3C home appliance industry, new energy industry and other areas of demand.

Flexible processing: as a flexible processing method, fiber laser can be combined with automated control system to realize automatic tracking, automatic edge finding, automatic nesting and other functions, thus improving the automation level and flexibility of the production line.

Strong environmental adaptability: due to its compact structure and good stability, fiber laser has lower requirements on the working environment and can work stably under more demanding conditions.

Economy: In addition to electricity consumption and a small amount of consumables costs, fiber laser cutting machine almost no other additional expenses, suitable for large-scale and small-scale production.

Although the fiber laser has many advantages in the field of cutting, but in the use of fiber laser cutting machine, we are still difficult to avoid the phenomenon of attenuation of the cutting efficiency, this time in the end which link is out of the problem?

Next we will analyze the potential causes of fiber laser cutting efficiency attenuation from a more in-depth perspective.

In the field of industrial laser processing, fiber laser cutting machine after a long period of high load operation state, there is a general phenomenon of gradual decline in cutting efficiency.

In addition to the conventional reasons may include lens contamination, focal length shift, insufficient gas pressure will lead to the above phenomenon, from a deeper perspective of analysis, we can also rank the following hidden triggers.

I. Quantum efficiency degradation due to pump source wavelength shift

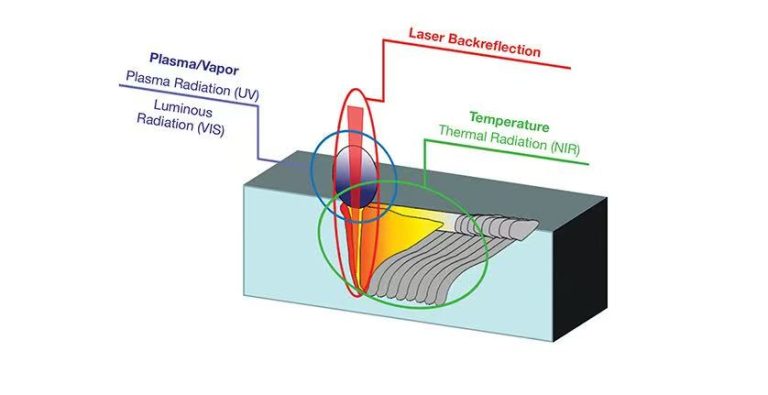

Conventional cognitive focus on the pump source power attenuation, but the actual test found:

980nm pump wavelength offset to the long wave direction of 0.5nm, ytterbium-doped fiber absorption efficiency can be reduced by up to 3.2

The wavelength stability of the 915nm band directly affects the thermal management efficiency, 0.8nm shift can lead to an increase in quantum loss by 1.8%

Semiconductor pump module aging caused by the spectral broadening effect, so that the effective pumping energy ratio decreased.

The hidden nature is reflected:

Conventional power meters are unable to detect changes in spectral characteristics

Wavelength shift initially has a weak effect on output power (<5%)

Long-term accumulation leads to irreversible damage to the gain medium

2. the progressive degradation of beam quality caused by higher-order mode excitation

Unlike the conventional optical component contamination problem, intrinsic beam degradation is manifested as:

Progressive degradation characterized by a weekly increase of 0.02 in the M² factor

Polarization degradation due to mode competition (typical values from >20dB to 15dB)

Elevated LP11 mode excitation probability induced by fiber bending loss

Key Parameter Correlations:

| Parameter change | Cutting speed decay rate | Increase in section roughness |

|---|---|---|

| M²+0.1 | 2.8% | 15μm |

| Eccentricity -1dB | 1.5% | 8μm |

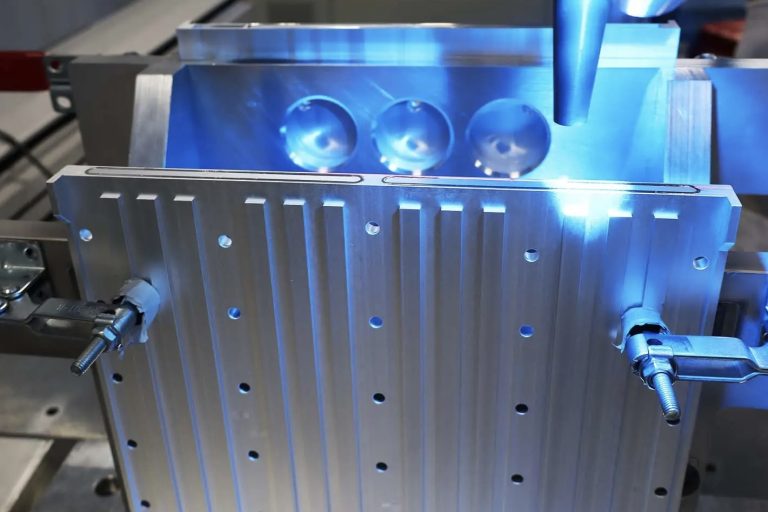

3. Thermal birefringence cumulative effect

In continuous operation, the polarization characteristics change triggered by the thermal effect of the fiber:

- Temperature gradients lead to changes in the birefringence coefficient of up to 3 × 10^-6/°C

- Polarization Dependent Loss (PDL) increase of 0.12dB/month

- Thermal stress-induced beat length change affects nonlinear effect thresholds

Typical performance:

- Periodic grain deepening when cutting stainless steel

- Increased oxide layer non-uniformity in aluminum cutting

- Copper processing plasma shielding effect increased

4. the acousto-optic modulator frequency response attenuation

Acousto-optic device performance degradation directly affects the quality of pulse processing:

- 20kHz modulation rise time from 120ns to 150ns

- Duty cycle control precision decreased by 0.8%

- Pulse front jitter increased to ±3ns

Impact on processing quality:

- 12% decrease in piercing success rate

- 25% increase in thin plate cutting burr rate

- Thick plate cutting taper change of 0.5°

5. Coolant dielectric properties decay

Traditional knowledge is limited to temperature control, ignoring the medium itself performance changes:

- Glycol solution capacitance rate of 2.3% annual decay rate

- Leakage current rise of 0.8mA/cm² due to increased ionic concentration

- Increase in dielectric loss angular tangent tanδ up to 15%.

Induced secondary problems:

- Reduced efficiency of the high voltage power supply system

- Reduced stability of RF drives

- 30% reduction in power electronics life time

When our fiber laser cutting efficiency decay, in addition to some conventional causes of inspection, we may need to find the root of the problem from a deeper perspective.

While fiber lasers offer advantages such as high efficiency, precision, and low maintenance, long-term operation may still lead to efficiency degradation caused by pump wavelength drift, beam quality deterioration, thermal birefringence effects, and more. Regular inspections and systematic maintenance can help identify and resolve these hidden issues, extending equipment lifespan and improving processing quality and productivity.